A super wear-resistant pvg flame retardant conveyor belt cover rubber

A conveyor belt, ultra-wear-resistant technology, applied in the field of conveyor belts, can solve the problems of short service life, high wear index, and high operating cost of conveyor belts, and achieve the effects of low cost, large transport volume, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

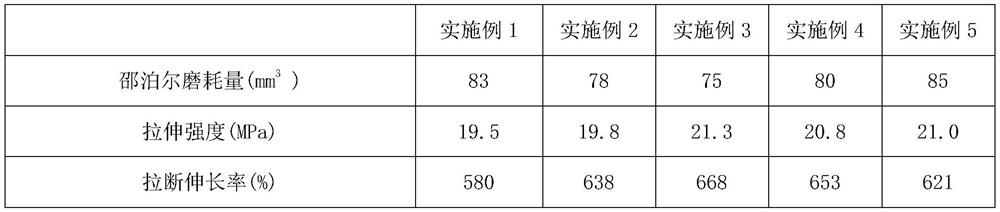

Examples

Embodiment 1

[0027] A super wear-resistant PVG flame-retardant conveyor belt cover rubber, which is composed of the following components by weight: 95 parts of SG-3 resin, 15 parts of dioctyl phthalate, tris (2-chloroethyl) phosphate 20 parts, 2 parts of tribasic lead sulfate, 4 parts of dibasic lead phosphite, 13 parts of triaryl phosphate, 5 parts of tetrapropylene titanate, 3 parts of antimony trioxide, 5213 parts of chlorinated paraffin, water 3 parts of zinc borate, 1 part of silane coupling agent, 1 part of dicumyl peroxide.

[0028] The preparation method of the super wear-resistant PVG flame-retardant conveyor belt cover glue comprises the following steps:

[0029] (1) Put SG-3 type resin, dioctyl phthalate, and tetrapropylene titanate into the internal mixer for 2 minutes, the speed is 40r / min, and then add tris (2-chloroethyl) phosphate , tribasic lead sulfate, dibasic lead phosphite, triaryl phosphate, antimony trioxide, chlorinated paraffin-52, zinc borate water, mixing for 5 ...

Embodiment 2

[0033]A super wear-resistant PVG flame-retardant conveyor belt cover rubber, which is composed of the following components by weight: 98 parts of SG-3 resin, 18 parts of dioctyl phthalate, tris (2-chloroethyl) phosphate 23 parts, 2 parts of tribasic lead sulfate, 4 parts of dibasic lead phosphite, 14 parts of triaryl phosphate, 6 parts of tetrapropylene titanate, 4 parts of antimony trioxide, 5214 parts of chlorinated paraffin, water 3 parts of zinc borate, 1 part of silane coupling agent, 1 part of dicumyl peroxide.

[0034] The preparation method of the super wear-resistant PVG flame-retardant conveyor belt cover glue comprises the following steps:

[0035] (1) Put SG-3 resin, dioctyl phthalate, and tetrapropylene titanate into the internal mixer for 3 minutes, the speed is 42r / min, and then add tris (2-chloroethyl) phosphate , tribasic lead sulfate, dibasic lead phosphite, triaryl phosphate, antimony trioxide, chlorinated paraffin-52, zinc borate water, mixing for 6 minute...

Embodiment 3

[0039] A super wear-resistant PVG flame-retardant conveyor belt cover rubber, which is composed of the following components by weight: 100 parts of SG-3 type resin, 20 parts of dioctyl phthalate, tris (2-chloroethyl) phosphate 25 parts, 3 parts of tribasic lead sulfate, 5 parts of dibasic lead phosphite, 15 parts of triaryl phosphate, 7 parts of tetrapropylene titanate, 5 parts of antimony trioxide, 5215 parts of chlorinated paraffin, water 3.5 parts of zinc borate, 2 parts of silane coupling agent, and 2 parts of dicumyl peroxide.

[0040] The preparation method of the super wear-resistant PVG flame-retardant conveyor belt cover glue comprises the following steps:

[0041] (1) Put SG-3 type resin, dioctyl phthalate, and tetrapropylene titanate into the internal mixer for 3 minutes, the speed is 43r / min, and then add tris (2-chloroethyl) phosphate , tribasic lead sulfate, dibasic lead phosphite, triaryl phosphate, antimony trioxide, chlorinated paraffin-52, zinc borate in wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com