Ceramic underglaze color material and manufacturing method thereof

A ceramic glaze and raw material technology, which is applied in the field of ceramic manufacturing, can solve problems such as difficulties in industrialized production, unfavorable industrialized production, and poor results of finished products, and achieve the effect of reducing the difficulty of writing and drawing, good viewing and collection value, and easy writing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

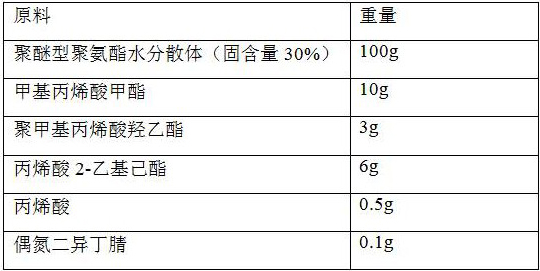

Embodiment 1

[0044]

[0045] (1) Take 120g of deionized water, heat it to 40°C, add methacrylic acid copolymer, shear at high speed to disperse, then slowly add Tween-80, oleic acid and isocyanate, and emulsify for 2 hours to obtain an emulsion;

[0046] (2) Take 40g of deionized water, heat it to 70°C, add hydroxypropyl methylcellulose, stir to dissolve, let cool to 40°C, add N-ethyl urethane, sodium succinate sulfonate, Stir to dissolve to obtain a mixed solution;

[0047] (3) Slowly add the emulsion to the mixed solution under high-speed shear, stir at 60°C for 2 hours, cool to room temperature, then add silicon dioxide and titanium dioxide, and stir for 30 minutes to obtain the product.

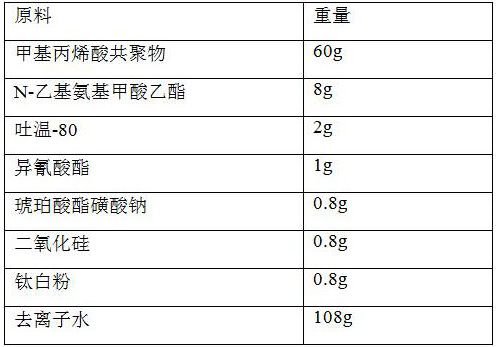

Embodiment 2

[0049]

[0050] (1) Take 90g of deionized water, heat it to 40°C, add ethyl acrylate-methyl methacrylate 1:1 copolymer, shear at high speed to disperse, then slowly add Tween-80, oleic acid and isocyanate, Emulsified for 4 hours to obtain an emulsion;

[0051] (2) Take 40g of deionized water, heat it to 70°C, add hydroxypropyl methylcellulose, stir to dissolve, let cool to 40°C, add N-ethyl urethane, sodium succinate sulfonate, Stir to dissolve to obtain a mixed solution;

[0052] (3) Slowly add the emulsion to the mixture under high-speed shear, stir at 60°C for 2 hours, cool to room temperature, then add silicon dioxide and titanium dioxide, and stir for 20 minutes to obtain the product.

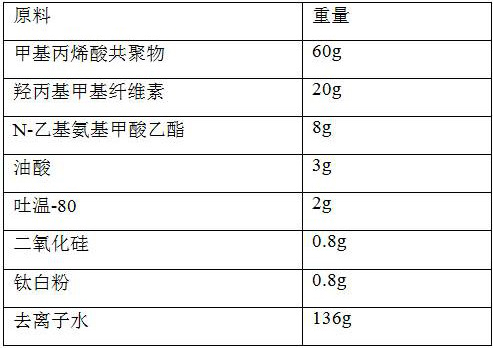

Embodiment 3

[0054]

[0055] (1) Take 100g of deionized water, heat it to 40°C, add dimethylaminoethyl methacrylate-methyl methacrylate 1:2 copolymer, shear at high speed to disperse, then slowly add Tween-80, Oleic acid and isocyanate were emulsified for 3.5 hours to obtain an emulsion;

[0056] (2) Take 50g of deionized water, heat it to 70°C, add hydroxypropyl methylcellulose, stir to dissolve, let cool to 40°C, add N-ethyl urethane, sodium succinate sulfonate, Stir to dissolve to obtain a mixed solution;

[0057](3) Slowly add the emulsion to the mixed solution under high-speed shear, stir at 60°C for 2 hours, cool to room temperature, then add silicon dioxide and titanium dioxide, and stir for 30 minutes to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com