Small-power large-load omnidirectional lifting trolley

An all-round, large-load technology, applied in the direction of hoisting device, gear transmission device, belt/chain/gear, etc., can solve the problem that the overall size of the transport trolley is difficult to meet the requirements of use, the load requirements of the transporter are high, and the workpieces carried are uneven, etc. To achieve the effect of simple and efficient maintenance, convenient and quick installation and disassembly, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

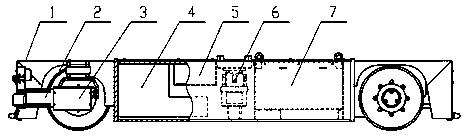

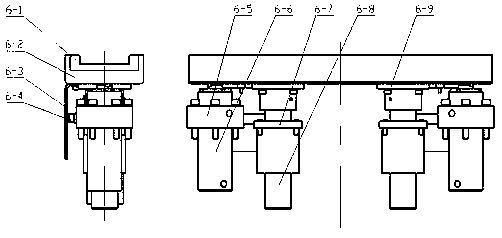

[0024] Such as figure 1 , 2 , 3, 4, and 5, a low-power and large-load lifting all-round trolley, including: car body 1, wheel train composition 2, driver 3, hydraulic station 4, electric control box 5, hydraulic lifting composition 6, Lithium battery pack 7; said wheel train composition 2 has four sets, which are connected to said car body 1 through a vehicle beam; said driver 3 is connected to said wheel train composition 2 through bolts; said hydraulic station 4, said electric Both the control box 5 and the lithium battery pack 7 are installed inside the vehicle body 1 through bolts; the hydraulic lift component 6 is connected to the middle load-bearing beam of the vehicle body 1 through bolts.

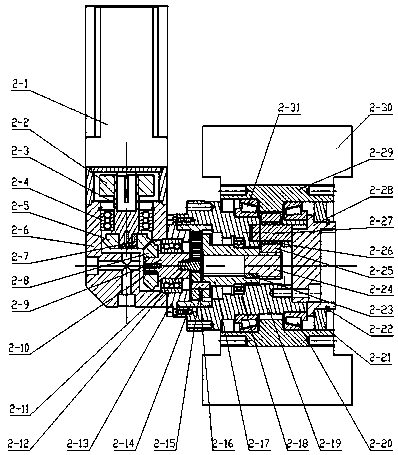

[0025] Such as figure 1 , 2, 3, 4, and 5, a low-power, high-load lifting omnidirectional trolley, the wheel train composition 2 includes: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com