Removal method of large-arm fracture inclination of high-altitude towercrane

A technology of tower crane and boom, which is applied in the field of high-altitude tower crane boom fracture and inclined removal, which can solve the problems of unbreakable tower body removal and other problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

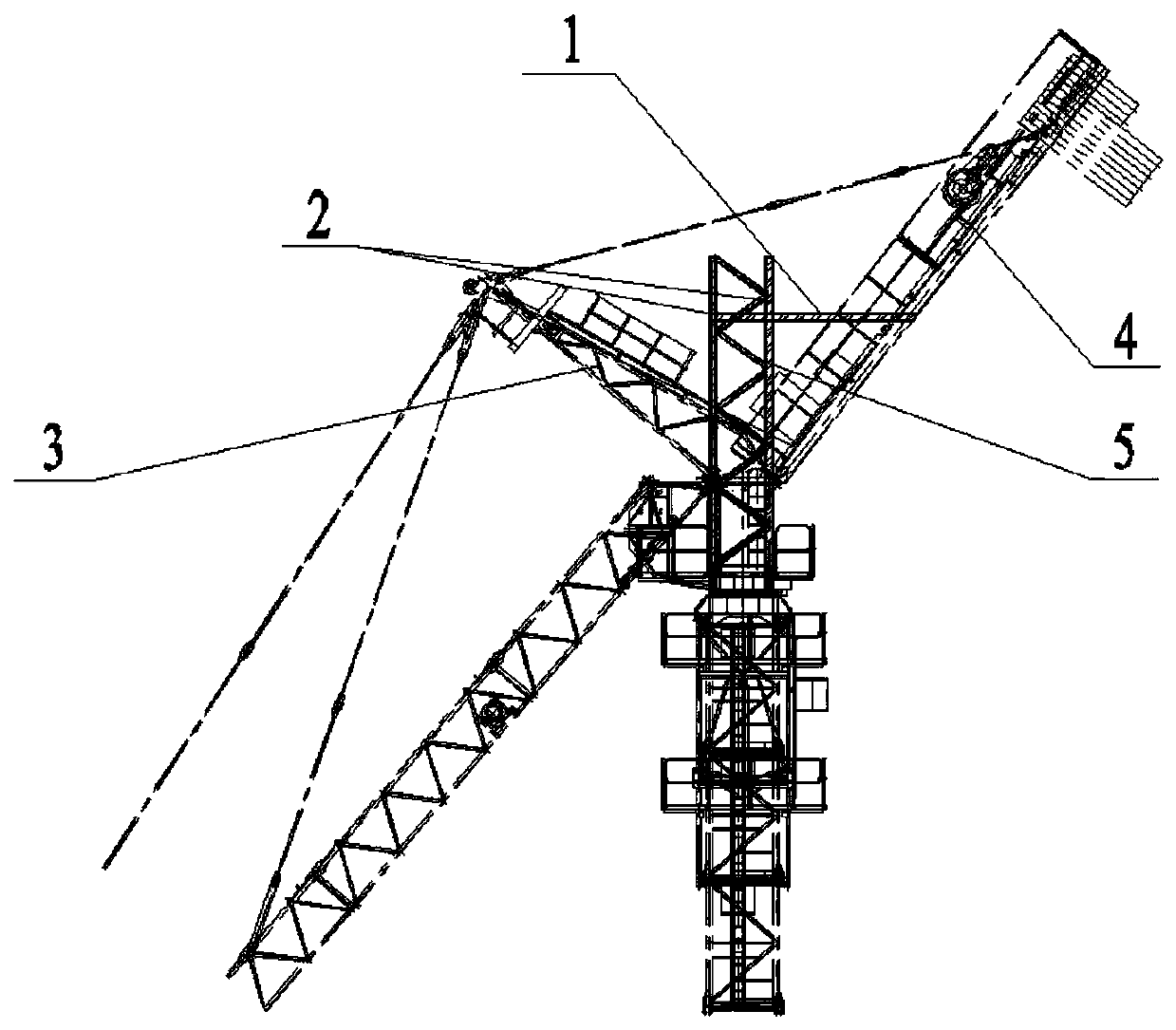

[0029] Due to improper use of a certain project, the boom of the high-altitude tower crane was broken and seriously tilted, and the tilted state of the tower body was backward. The analysis shows that the bending moment in the direction of the balance arm is greater than that in the direction of the lifting arm. The tower crane tilts back 50mm toward the balance arm. The total station is used to accurately survey and map the attitude of the existing tower crane on the hoisting plane passing through the center of the tower body and perpendicular to the tower crane. Through the joint analysis of relevant experts, it is judged that there is also tensile stress in the diagonal brace of the front piece of the tower top in this state. The diagonal brace of the tower top in the direction of the boom needs to be welded and strengthened. The tower crane that is tilted should be dismantled as soon as possible, which will reduce the risk, Resume on-site construction. The demolition hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com