Moisture-proof noise-proof sheet

A noise-proof and plank technology, which is applied in the direction of wood processing appliances, wooden veneer joints, lamination, etc., can solve problems such as poor quality, poor tightness, and easy deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

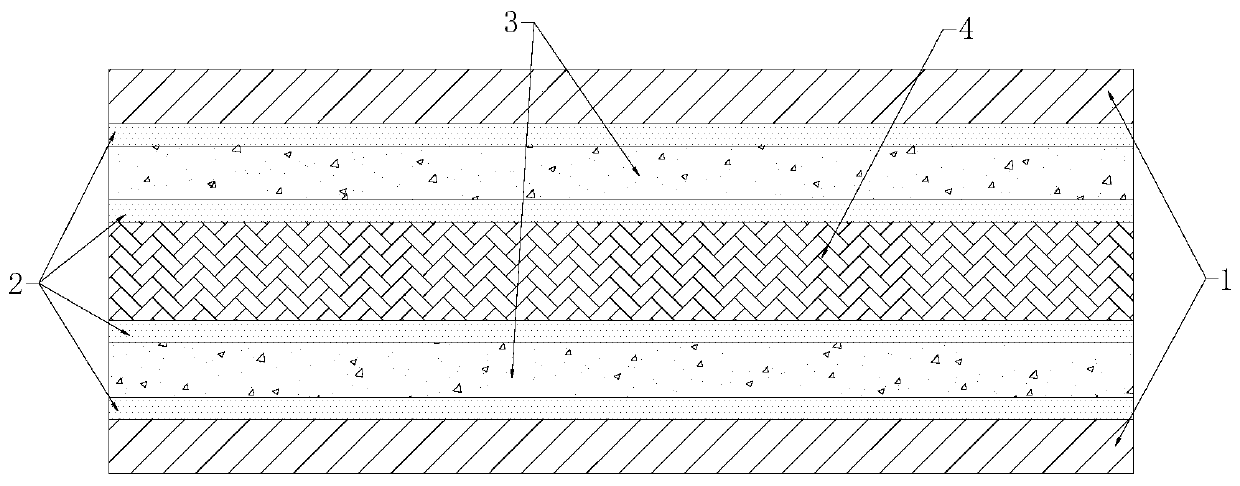

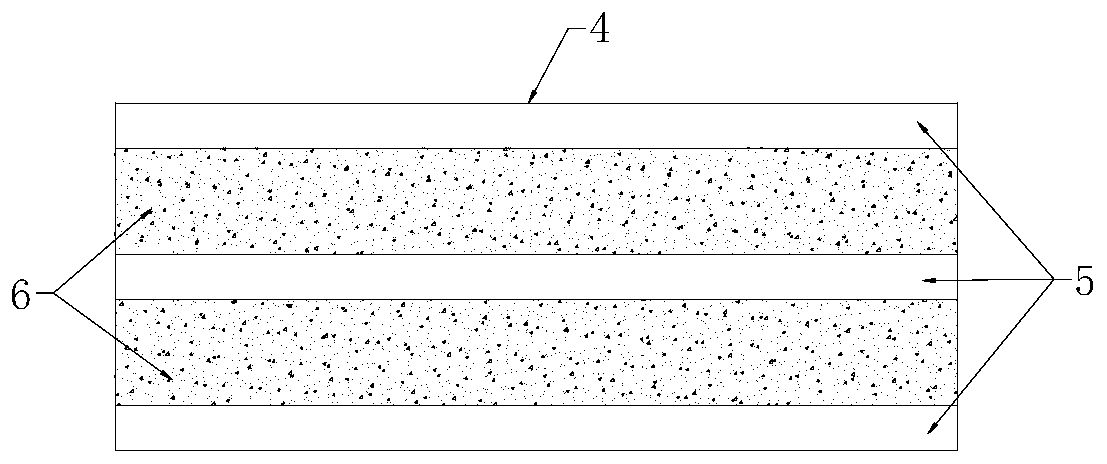

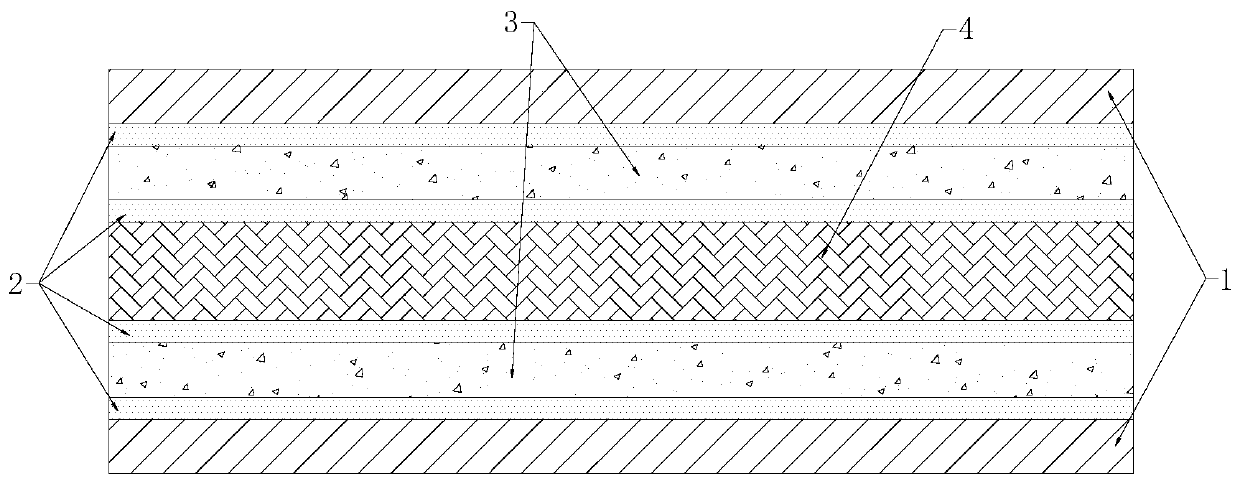

[0029] Example: such as Figure 1-2 As shown, a moisture-proof and noise-proof board includes a decorative layer 1, an adhesive 2, a moisture-proof layer 3, and a sound-insulating layer 4. They are respectively connected with the decorative layer 1 and the sound-insulating layer 4 as a whole, wherein the sound-insulating layer 4 is composed of several layers of plastic films 5 and a sound-insulating filling layer 6 between every two layers of plastic films 5 .

[0030] The number of several layers of plastic films 5 is ≧3, and the thickness of each layer of plastic films 5 is not the same, and each layer of plastic films 5 is a plastic film with undulating surface and uneven surface, which can form an absorption peak for absorbing noise, thereby achieving excellent Sound absorption and noise reduction effect.

[0031] Adhesive 2 is an ant-proof adhesive, which has the function of preventing insects and ants.

[0032] The plastic film 5 is made of one or more materials in PE,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com