Automatic injection pipe production device

A technology of automatic production and grouting pipe, applied in the field of automatic production of grouting pipe and automatic production equipment of grouting pipe, to achieve the effect of strong adaptability, improving the efficiency and quality of hot-melting, and saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

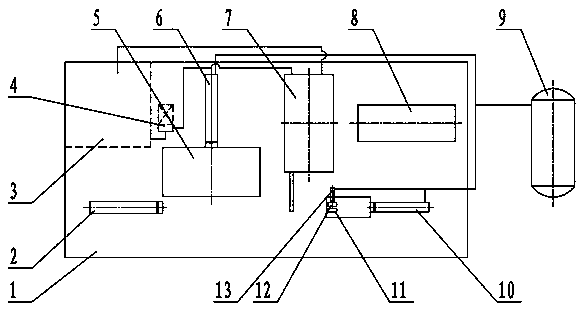

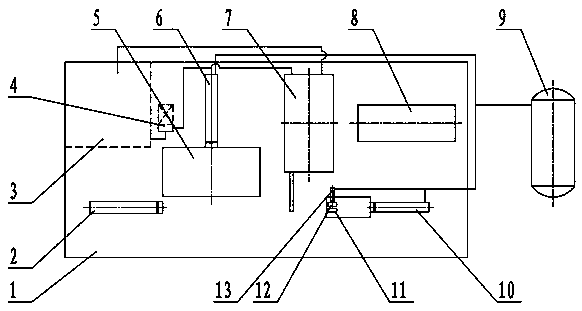

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] combine figure 1 with figure 2 , it can be seen that the automatic production equipment for grouting pipes of the present invention includes a workbench 1, and also includes a high-frequency fuser 7, a material feeding device, a pneumatic linkage device, a computer numerical control device, a cooling circulation pump 4 and a water tank 3, and an air pump 9.

[0024] The blanking and feeding device is composed of a blanking slide 5, a pneumatic push rod I6, and a pneumatic push rod II2; wherein, the blanking slide 5 cooperates longitudinally with the pneumatic push rod I6, and the blanking slide 5 cooperates horizontally with the pneumatic push rod II2.

[0025] The pneumatic linkage device is composed of clamp I11, clamp II12, pneumatic push rod III13, and pneumatic push rod IV10; among them, clamp I11 and clamp II12 cooperate; pne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com