Electric Field Driven Droplet Jetting Nozzle Based on Pyroelectric Effect

A droplet spraying and pyroelectric technology, applied in coating devices, manufacturing tools, additive manufacturing, etc., can solve problems such as the influence of the stability of the printing process, and achieve a stable effect of the printing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

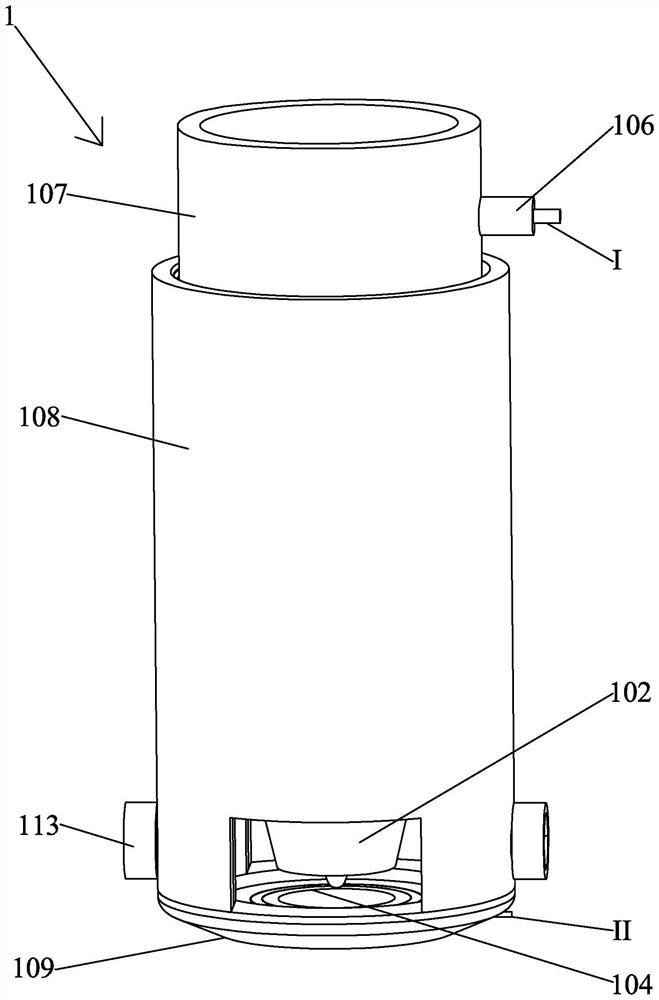

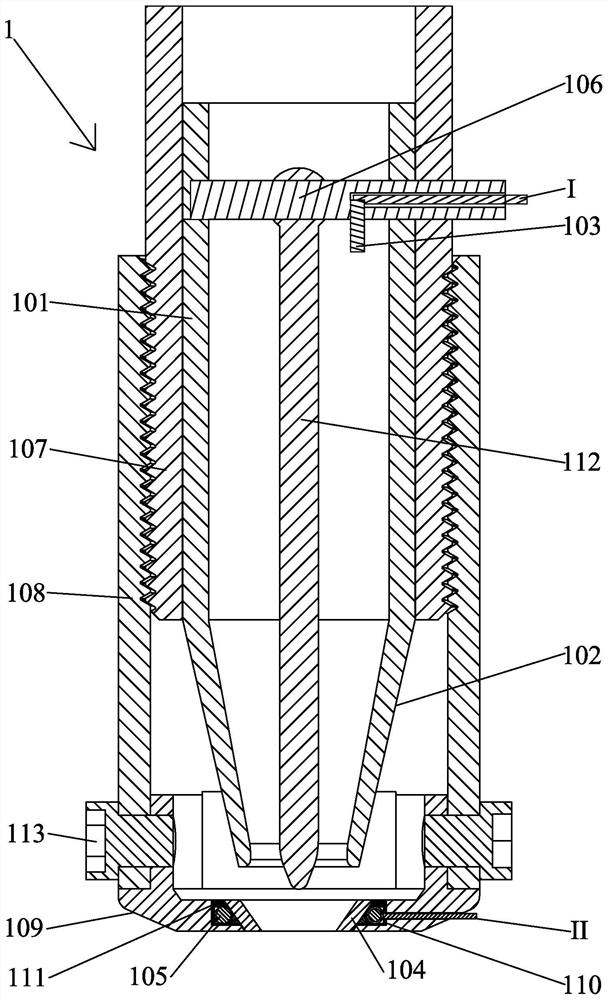

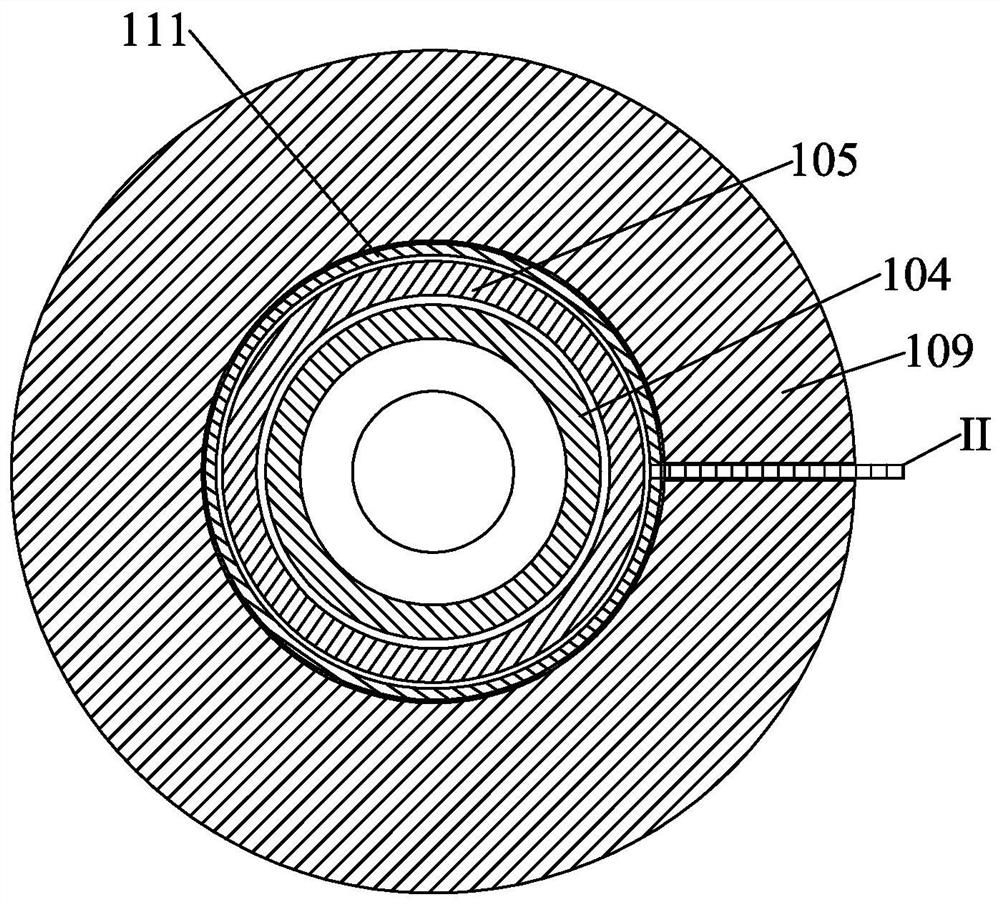

[0027] What the present invention discloses is a kind of electric field-driven droplet spray nozzle based on pyroelectric effect, such as Figure 1 to Figure 3 Shown is a preferred embodiment of the droplet ejection head of the present invention. The spray nozzle 1 includes a storage tank 101, a nozzle 102, an electrode 103, a pyroelectric crystal ring 104, a heating ring 105 and a casing. in:

[0028] The nozzle 102 is arranged below the storage tank 101, and the two can be integrally formed, or can be a separate interconnected structure, and the nozzle 102 is tapered.

[0029] The electrode 103 is arranged in the storage tank 101. Specifically, a beam 106 is arranged above the storage tank 101 to run through the inside and outside of the storage tank 101, and a hollow structure connecting the inside and outside of the storage tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com