Intelligent automation household plate material punching device

A punching device and plate technology, applied in the field of plate processing, can solve problems affecting efficiency, punching, and tediousness, and achieve the effect of improving efficiency and accuracy and preventing inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

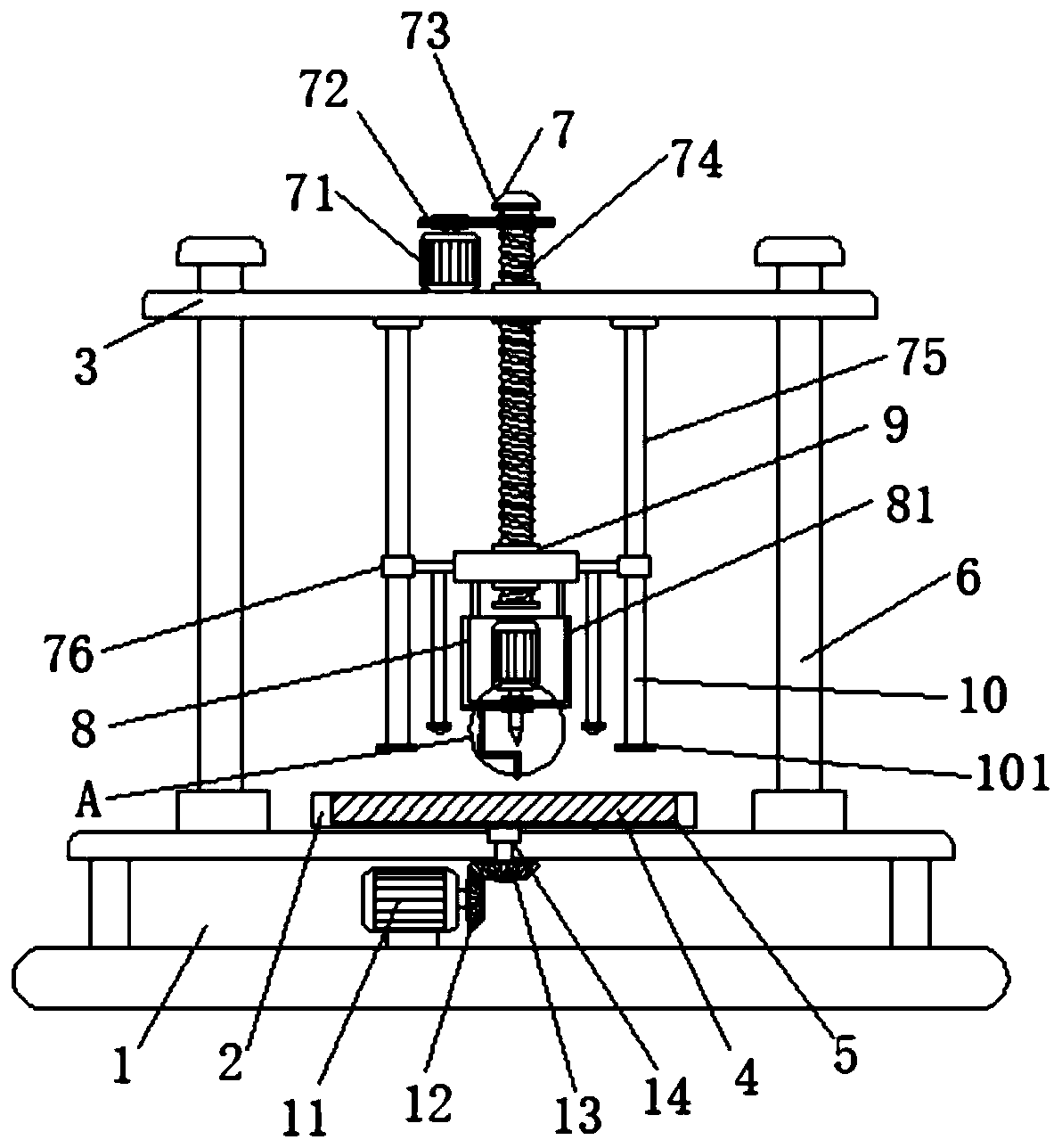

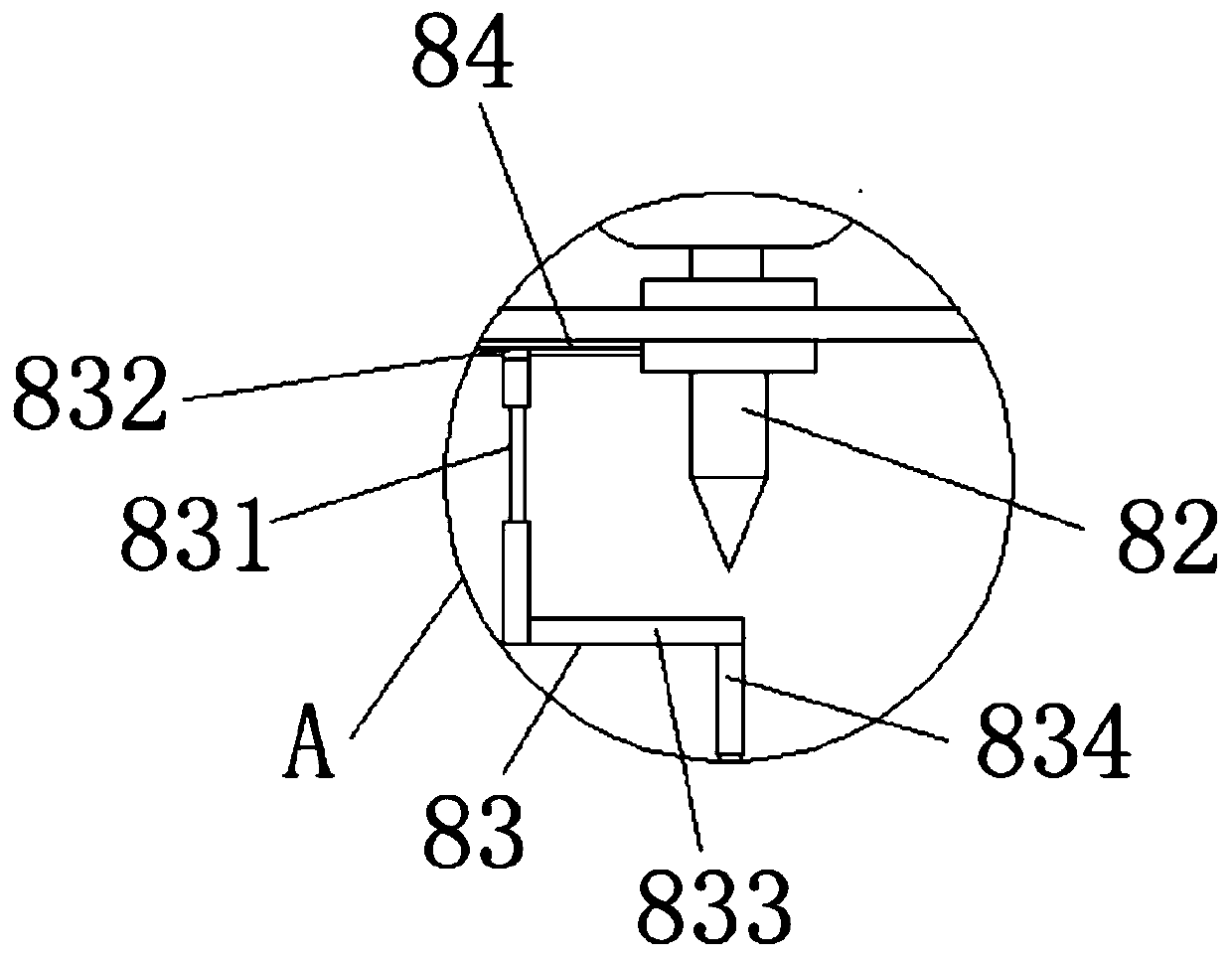

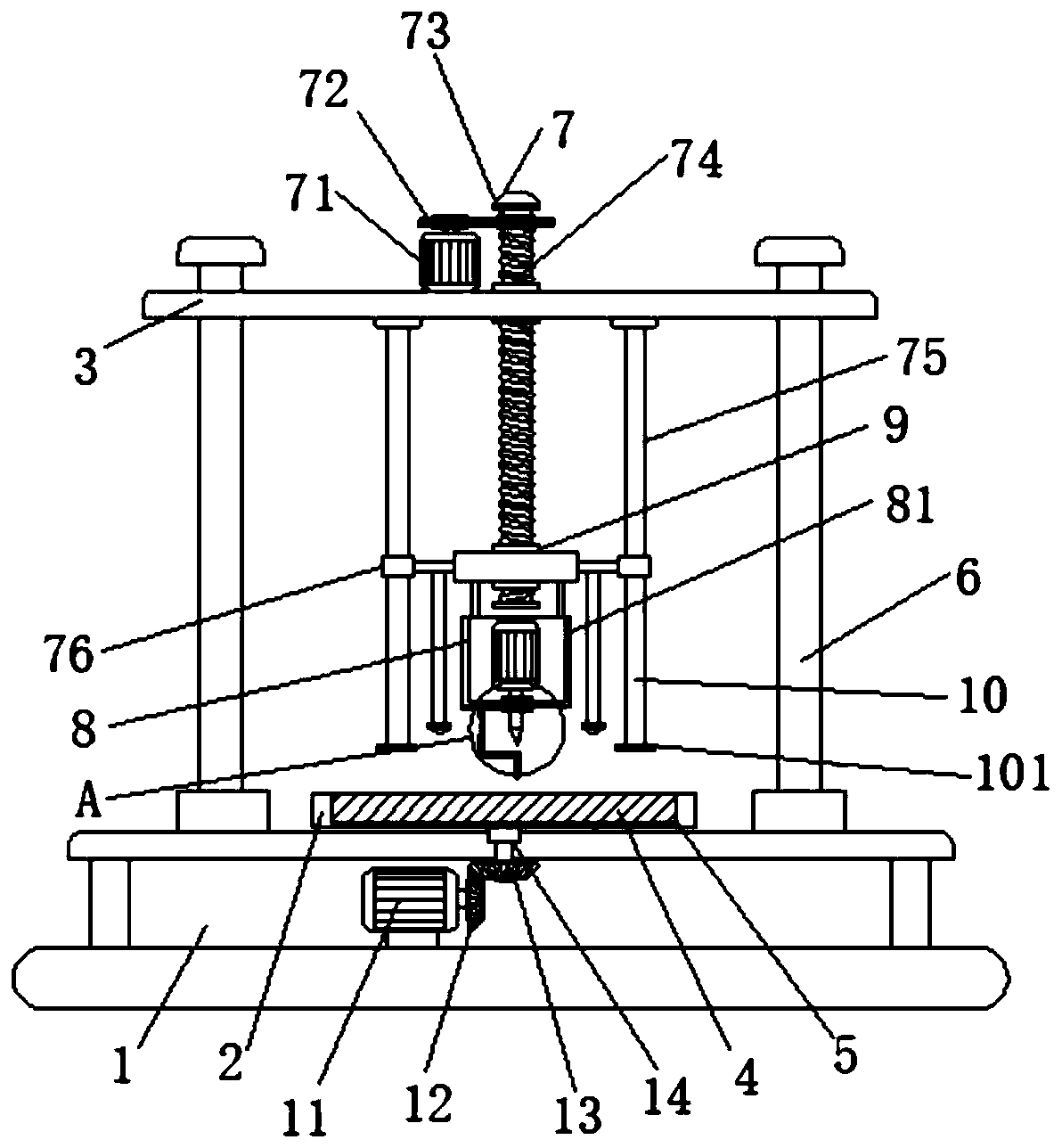

[0026] Example: such as Figure 1-2 As shown, the present invention provides an intelligent automation home plate punching device, including a base plate 1 and a punching mechanism 8, the base plate 1 is placed on a horizontal plane, and above it, a placement base plate 2 and a mounting plate 3 are sequentially arranged in parallel; The placement substrate 2 is used to place the home board 4, and it has a placement groove 5, and the home board 4 is fitted and fixed in the placement groove 5; the two sides of the placement groove 5 are provided with support columns 6, and one end of the support column 6 is fixed On the base plate 1, the other end thereof extends upwards along the vertical direction with the base plate 1, and the support column 6 is connected to the mounting plate 3; a lifting device 7 is installed on the mounting plate 3, and the lifting device 7 is used for elevating the punching mechanism 8. Including a motor one 71, a driving gear 72 and a driven gear 73, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com