Equipment and process for pipeline welding by using auxiliary positioning device

An auxiliary positioning and pipeline technology, which is applied in the direction of auxiliary welding equipment, auxiliary devices, welding equipment, etc., can solve the problems of pipeline deformation and dislocation, labor and time consumption, etc., and achieve the effect of enhancing strength, improving work efficiency, improving efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments. The exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

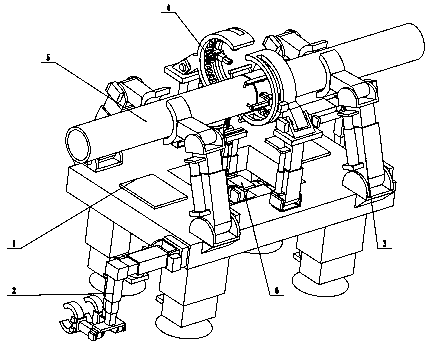

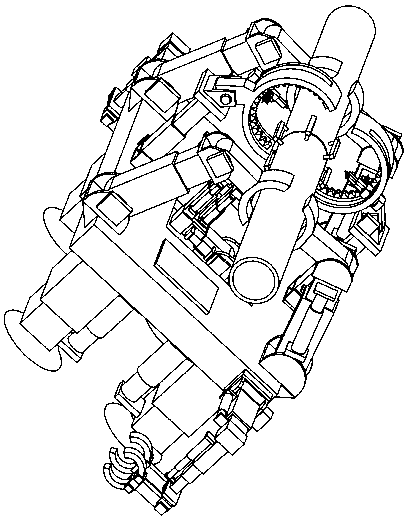

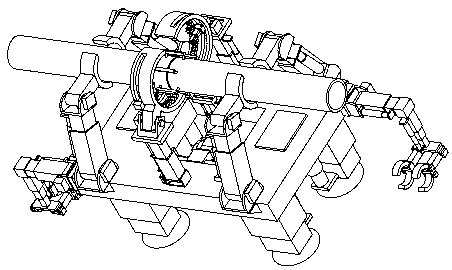

[0029] Example figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 As shown, an equipment and process for welding pipelines using an auxiliary positioning device, including a base support part 1, a grabbing part 2, a fixing part 3, a welding part 4, a pipe display part 5, and a punching nail gun part 6. The first motor 201 of the grasping part 2 is fixedly installed on the front end face of the bottom plate 101 of the base support part 1; Connection; the bottom end face of the sixth support 401 of the welding part 4 is fixedly connected with the upper end face of the bottom plate 101 of the base support part 1; the bottom end fac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com