Precise portable type manual sheet bending machine and operating method thereof

A portable bending machine technology, applied in the field of mechanical processing and manufacturing, can solve the problems that the bending angle is difficult to achieve the expected accuracy, high production cost, limited space, etc., to achieve high product precision, low cost, and accurate bending angle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

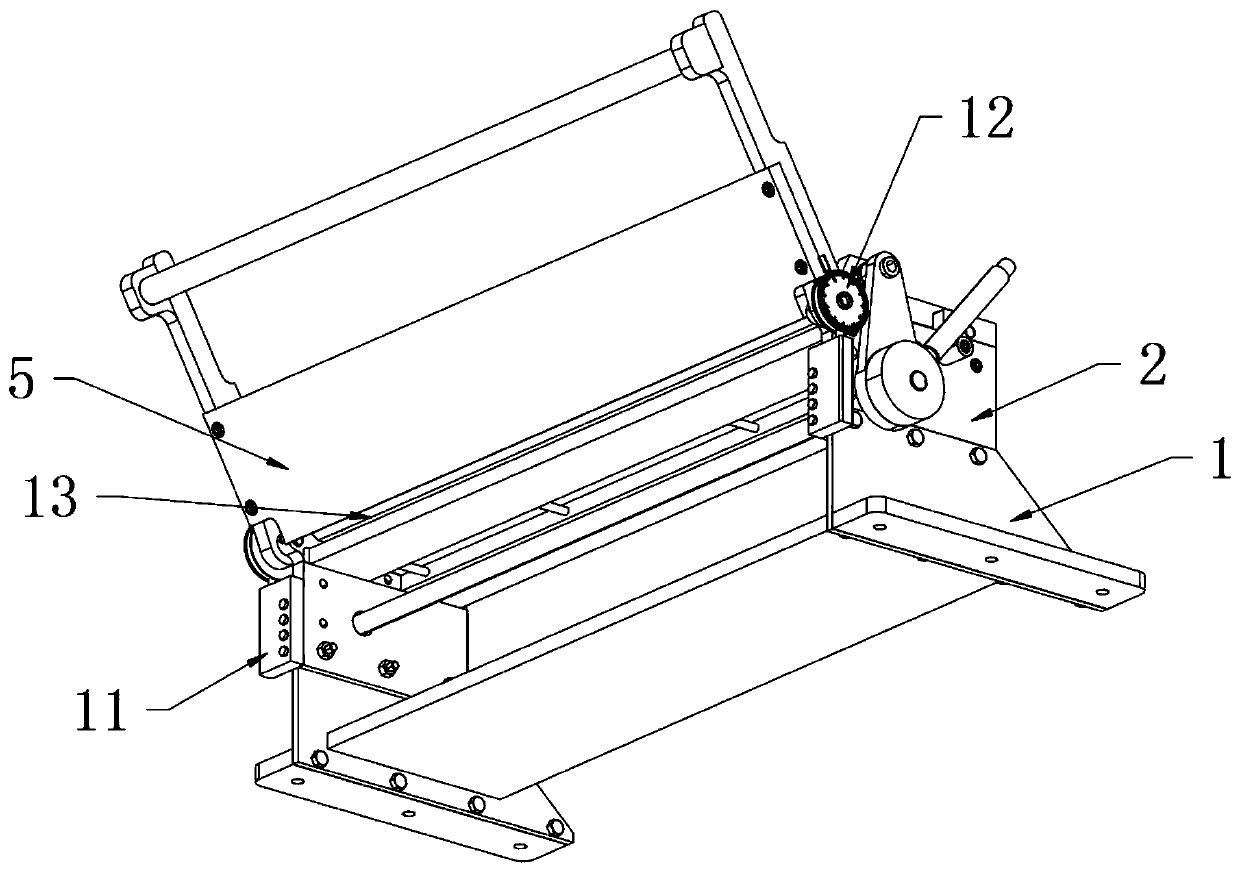

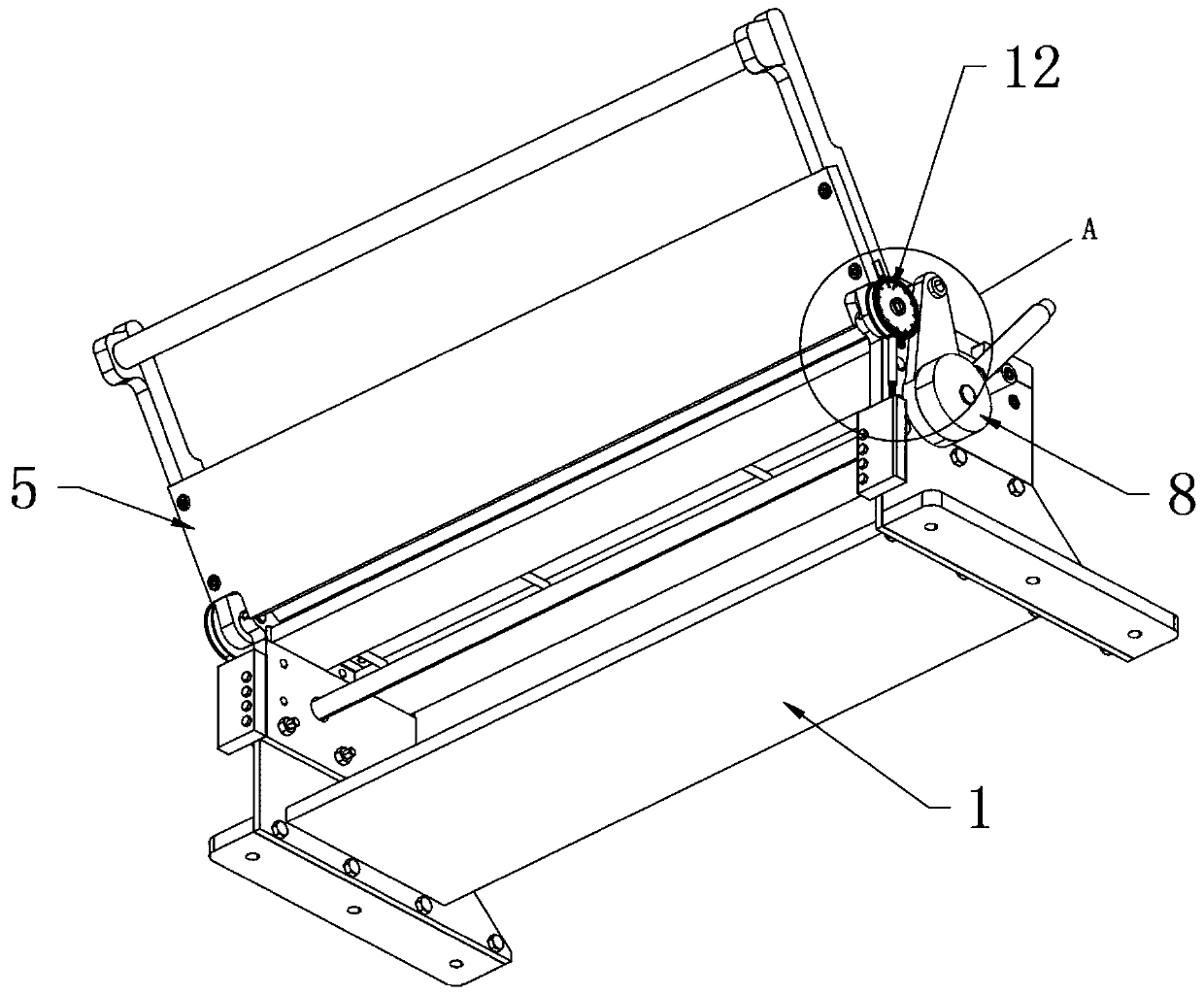

[0024] as attached figure 1 to attach Figure 4 Shown:

[0025] The present invention provides a precise and convenient manual thin plate bending machine, including a base 1, a side plate 2, a groove 201, a bottom plate 3, a pressure plate 4, a bending plate 5, a first rotating pin 6, a limit column 7, a runner 8, Connecting plate 9, second rotating pin 10, angle limit box 11, angle plate 12, side groove 1201, socket 1202, inner plate 13, pointer 14, positioning column 15 and spring 16; the left and right sides of the base 1 The side plates 2 are fixedly installed by bolts; the upper ends of the inner opposite side walls of the two parallel side plates 2 are inlaid with the bottom plate 3 through the groove 201; the top front end of the side plates 2 is rotated by the first rotating pin 6 It is connected to the two ends side plates of the pressing plate 4, and the rear end of the pressing plate 4 is connected to the rear end of the side plate 2 through the rotation of the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com