Glass glue fast curing equipment for glass doors and windows

A fast-curing, glass glue technology, used in mechanical equipment, devices for coating liquid on the surface, connecting components, etc., can solve problems such as prolonging the curing time of glass glue, affecting the production efficiency of glass doors and windows, and achieving accelerated curing time, Reduce curing time, increase air circulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

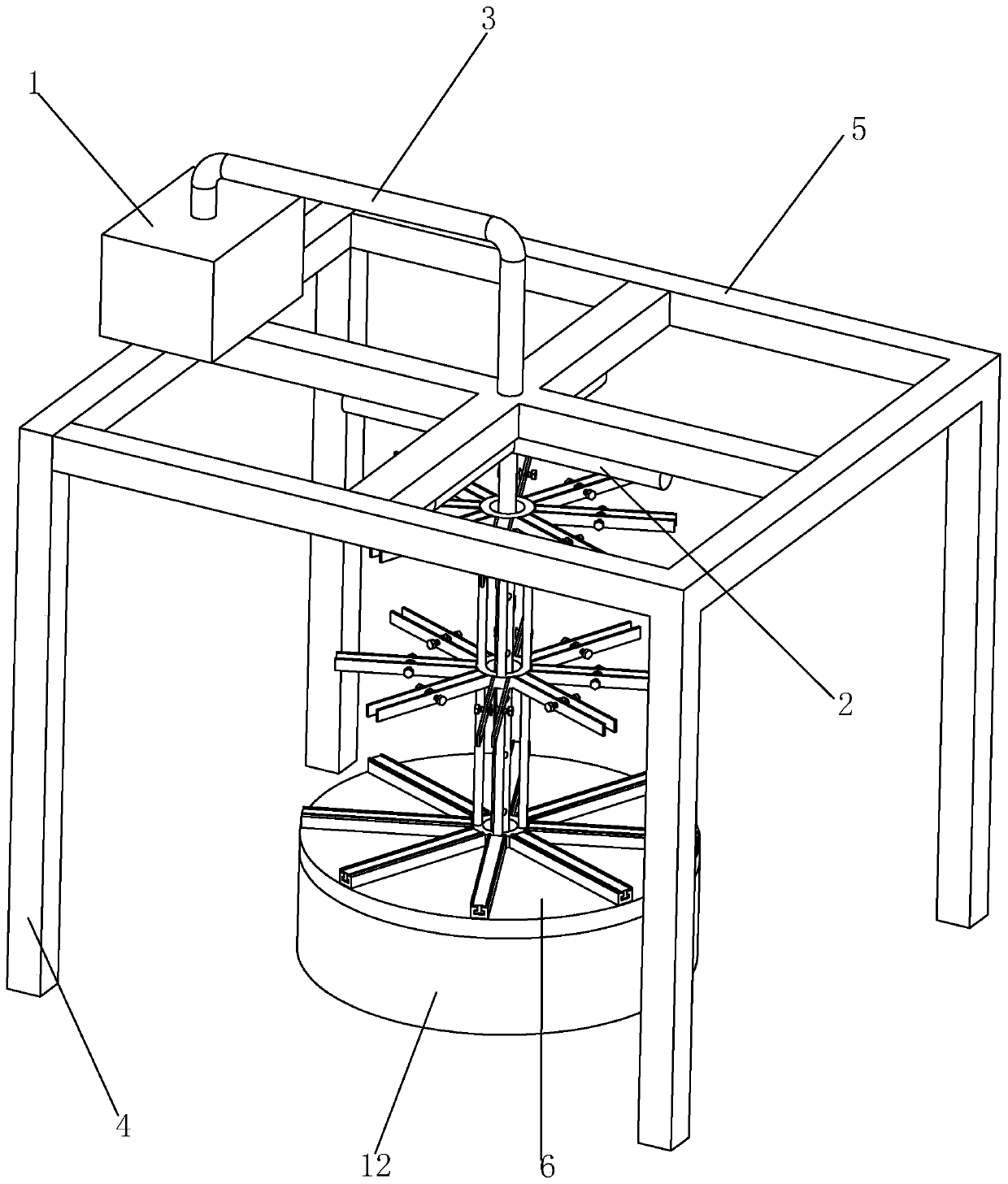

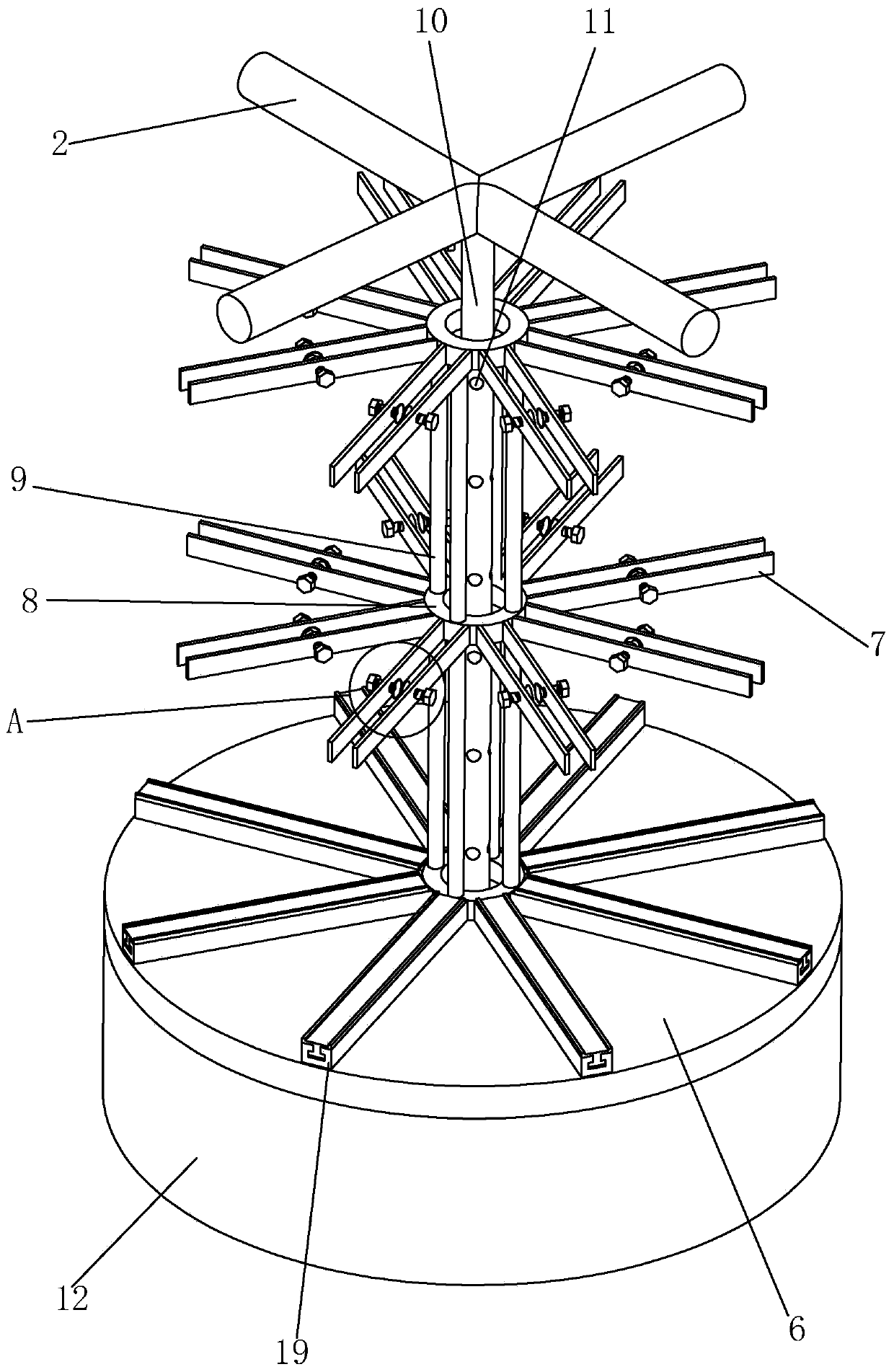

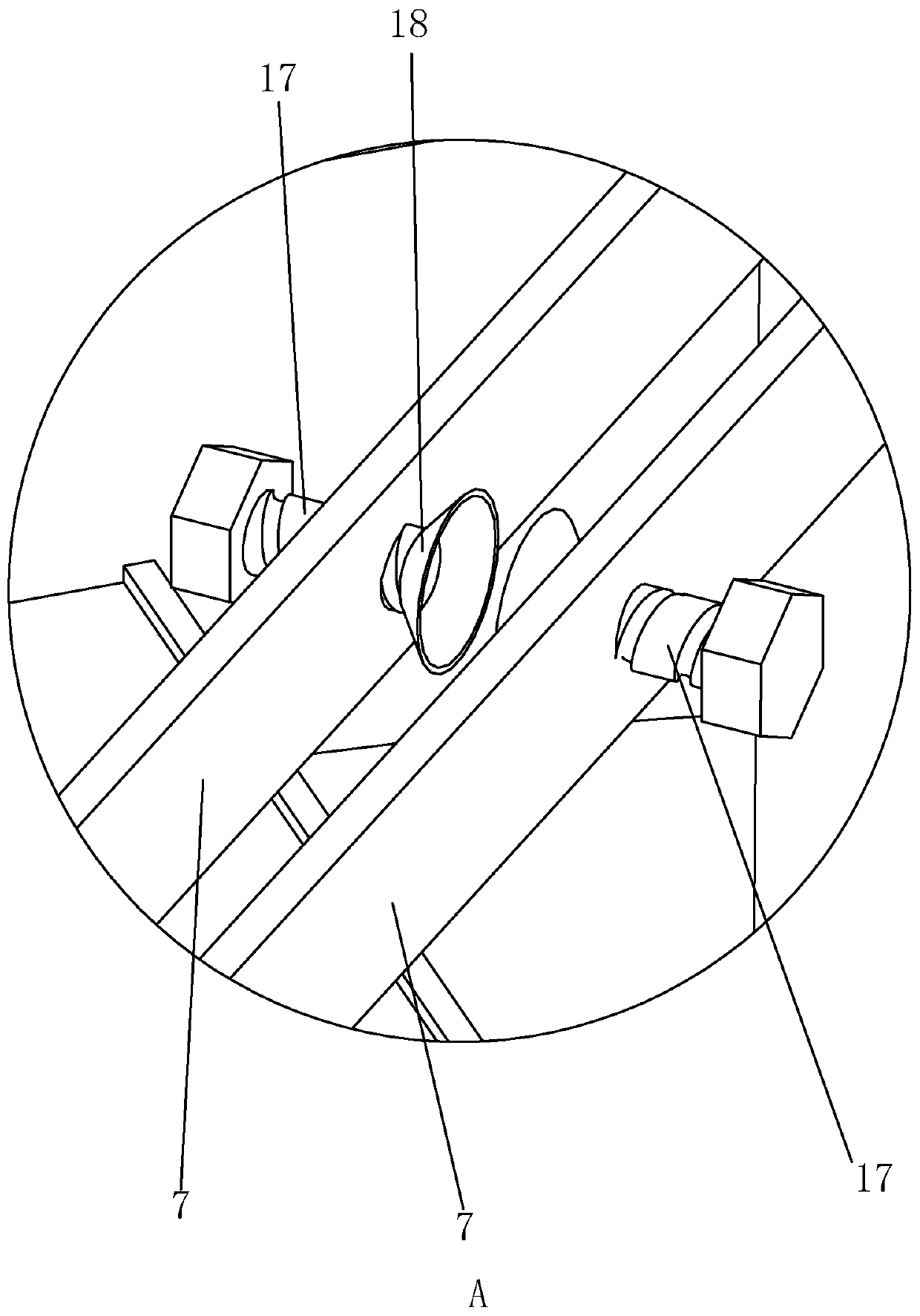

[0036] A glass glue fast curing equipment for glass doors and windows, such as figure 1 As shown, it includes a placement frame, a mounting frame, a humidifier 1, and a humidifying tube 2. The mounting frame is used to place glass doors and windows at intervals. The mounting frame is located in the mounting frame. and is connected to the humidifier 1 through the connecting pipe 3. There are several humidification holes (not shown in the figure) axially spaced on the wall of the humidification pipe 2, and the several humidification holes face between two adjacent glass doors and windows of the shelf. The gap between the glass doors and windows with glass glue is placed on the shelf at intervals, and the moisture generated by the humidifier 1 on the mounting shelf flows to the humidifying pipe 2 through the connecting pipe 3, and then flows to the shelf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com