Automatic preparation device for filling material of rock test specimen

A technology for automatic preparation of rock specimens, applied to mixers with rotating stirring devices, mixer accessories, mixers, etc., can solve problems such as high work intensity, human health hazards, and low work efficiency, and achieve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

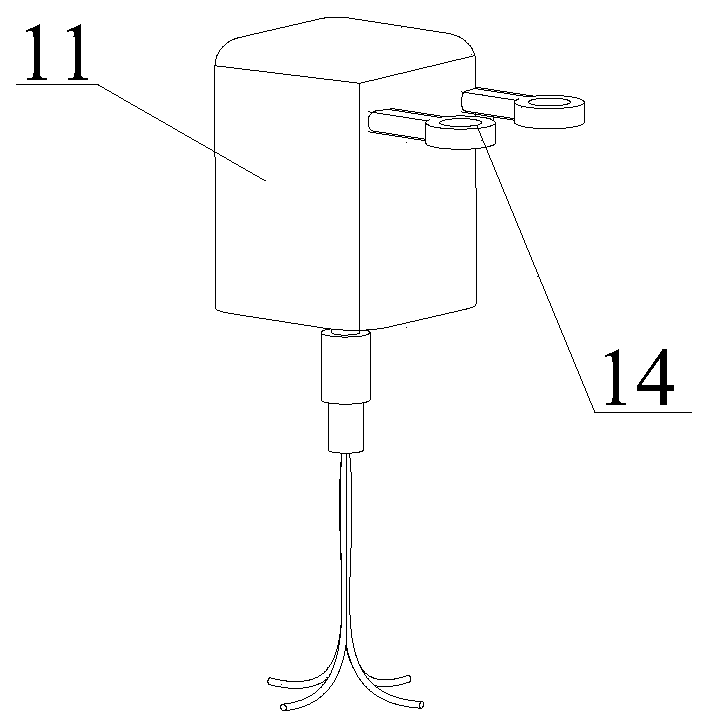

[0015] refer to Figure 1 to Figure 5 , the present invention is an automatic preparation device for rock specimen filler, which consists of a workbench [1]; a tray bracket [2]; a mixing and stirring motor [3]; a control unit [4]; an electronic scale [5]; Motor [6]; Spreading funnel [7]; Funnel bracket [8]; Mixer [9]; Mixer moving frame [10]; Stirring motor [11]; Moving shaft [12]; Water injector [13] ]; fixed nut [14]; rotating motor [15]; bracket screw hole [16].

[0016] The funnel bracket [8] is installed on the spreading motor [6], the spreading funnel [7] is installed on the funnel bracket [8]; the mixer moving frame [10] is installed on the rotating motor [15] ], the four mixers [9] are connected to the mixer moving frame [10] through the bracket screw holes [16], and the mixer [9] can be moved to different stations by rotating the motor [15] ; The workbench [1] is fixed on the horizontal platform for placing the mixer [9]; the moving shaft [12] is fixed behind the wo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com