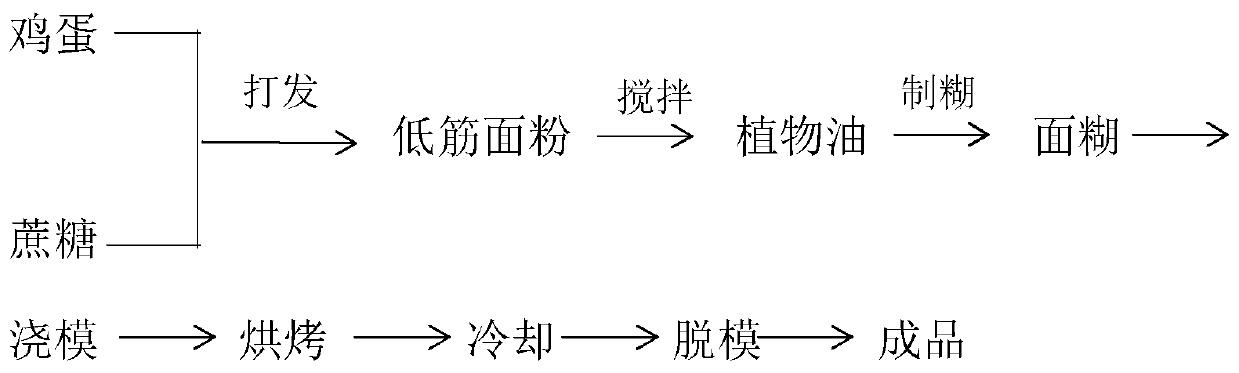

Making method of low-temperature resistant ageing resistant cakes

A production method and anti-aging technology, which is applied in the direction of dough processing, baking, baked food with modified ingredients, etc., can solve the problems of insufficient emulsification, poor cake taste, and inability to fully utilize food colloids, etc., to achieve Effects of anti-aging, enhanced anti-aging performance, and improved low-temperature storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

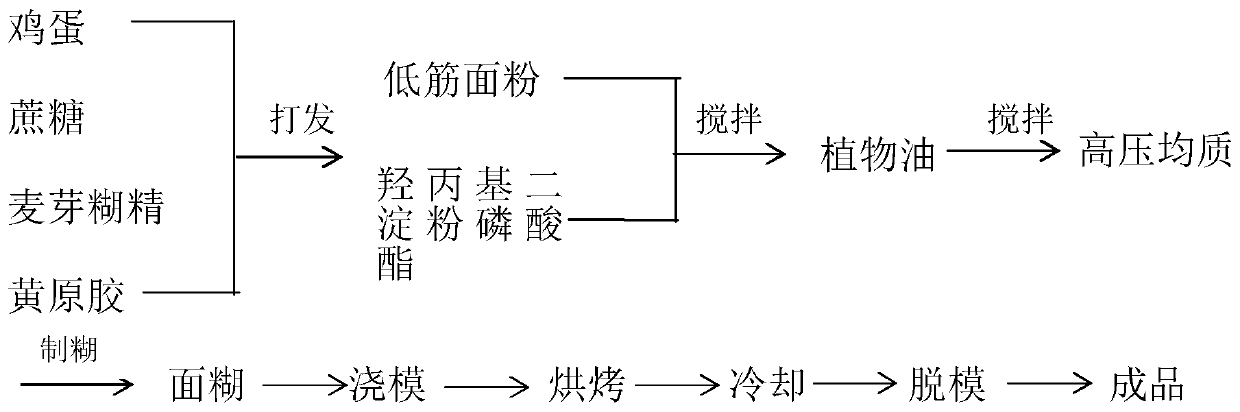

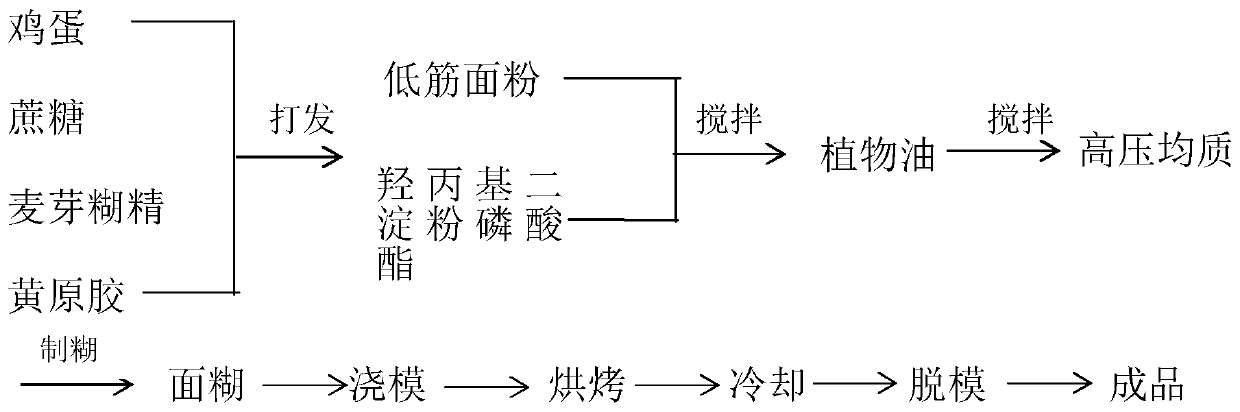

Method used

Image

Examples

Embodiment 1

[0040] (1) Mix 0.2g maltodextrin and 0.05g xanthan gum evenly according to the mass ratio of 0.2:0.05 to obtain a mixture of maltodextrin and xanthan gum; select fresh eggs, beat them into a uniform egg liquid, weigh 149.75g of sucrose, Put 100g of egg liquid, 0.25g of the mixture of maltodextrin and xanthan gum in a blender, and beat at a speed of 80r / min for 30s, then at a speed of 800r / min for 10min, until it becomes a milky white foam;

[0041] (2) Add 214.3g of low-gluten flour and 10.7g of hydroxypropyl distarch phosphate, and continue beating at a speed of 800r / min for 10 minutes to form a paste, so that the flour and egg paste are fully mixed. The amount of low-gluten flour accounts for the total mass of the material 45% of hydroxypropyl distarch phosphate accounts for 5% of the mass of low-gluten flour;

[0042] (3) Add 25g vegetable oil to the cake batter that has been stirred, and whip for 3 minutes at a speed of 1000r / min to obtain the batter emulsified for the fir...

Embodiment 2

[0048] (1) Mix 0.5 g of maltodextrin and 0.25 g of xanthan gum evenly according to the mass ratio of 0.3:0.15 to obtain a mixture of maltodextrin and xanthan gum; select fresh eggs, beat them into a uniform egg liquid, weigh 117.5 g of sucrose, Put 96.75g of egg liquid, 0.75g of the mixture of maltodextrin and xanthan gum into a blender, first beat at a speed of 100r / min for 35s, then at a speed of 900r / min for 8min, until it becomes milky white foam;

[0049] (2) Add 233.6g of low-gluten flour and 16.4g of hydroxypropyl distarch phosphate, and continue beating at a speed of 900r / min for 8 minutes to form a paste, so that the flour and egg paste are fully mixed. The amount of low-gluten flour accounts for the total mass of the material 50% of the mass of low-gluten flour, and hydroxypropyl distarch phosphate accounts for 7% of the mass of low-gluten flour;

[0050] (3) Add 35g vegetable oil to the cake batter that has been stirred, and whip for 2.5min at a speed of 1100r / min t...

Embodiment 3

[0056] (1) Mix 0.4g maltodextrin and 0.1g xanthan gum evenly according to the mass ratio of 0.4:0.1 to obtain a mixture of maltodextrin and xanthan gum; select fresh eggs, beat them into a uniform egg liquid, weigh 92.5g of sucrose, Put 92g of egg liquid, 0.5g of the mixture of maltodextrin and xanthan gum in a blender, first beat at a speed of 120r / min for 40s, then at a speed of 1000r / min for 10min, until it becomes milky white foam;

[0057] (2) Add 250g of low-gluten flour and 25g of hydroxypropyl distarch phosphate, and continue beating at a speed of 1000r / min for 5 minutes to form a paste, so that the flour and egg paste are fully mixed. The amount of low-gluten flour accounts for 55% of the total mass of the material. %, hydroxypropyl distarch phosphate accounts for 10% of the mass of low-gluten flour;

[0058] (3) Add 40g vegetable oil to the cake batter that has been stirred, and whip for 3min at a speed of 1200r / min to obtain the batter emulsified for the first time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com