Method for catalyzing levulinic acid or levulinic acid ester to gamma-valerolactone by in-situ reduction of basic copper carbonate/hydroxyl aluminium oxide

A technology for catalyzing levulinic acid and aluminum oxyhydroxide, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve problems such as increased production costs and high reaction temperatures , to achieve good catalytic activity, simple reaction system, and strong operational safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 0.67mmol methyl levulinate, 0.1g Cu 2 (OH) 2 CO 3 / AlOOH (Cu / Al=3 / 1) and 20ml of isopropanol were placed in a 35mL autoclave. After the autoclave was sealed, the reaction was stirred at 180°C for 5h. After the autoclave was cooled, it was tested.

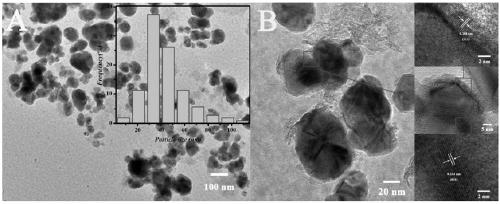

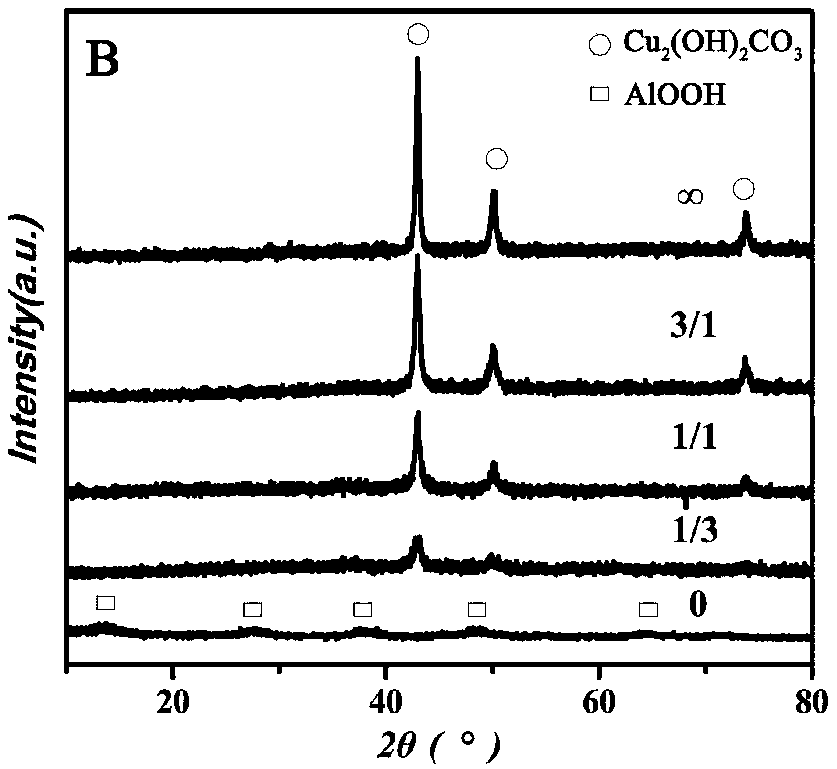

[0046] where Cu 2 (OH) 2 CO 3 The preparation method of / AlOOH catalyst is: with 3.624g Cu (NO 3 ) 2 ·3H 2 O and 1.875gAl 2 (NO 3 ) 3 9H 2 O was dissolved in 40 mL of deionized water and stirred at room temperature for several minutes; subsequently, with 1mol / L Na 2 CO 3 Adjust the pH of the solution to 8-9, stir for ten minutes, and let it stand overnight; then filter it with suction, wash it four or five times with deionized water, and dry it in an oven at 80°C; then grind it and bake it in a muffle furnace at 200°C. Finally, Cu with a Cu / Al molar ratio of 3 / 1 is obtained 2 (OH) 2 CO 3 / AlOOH.

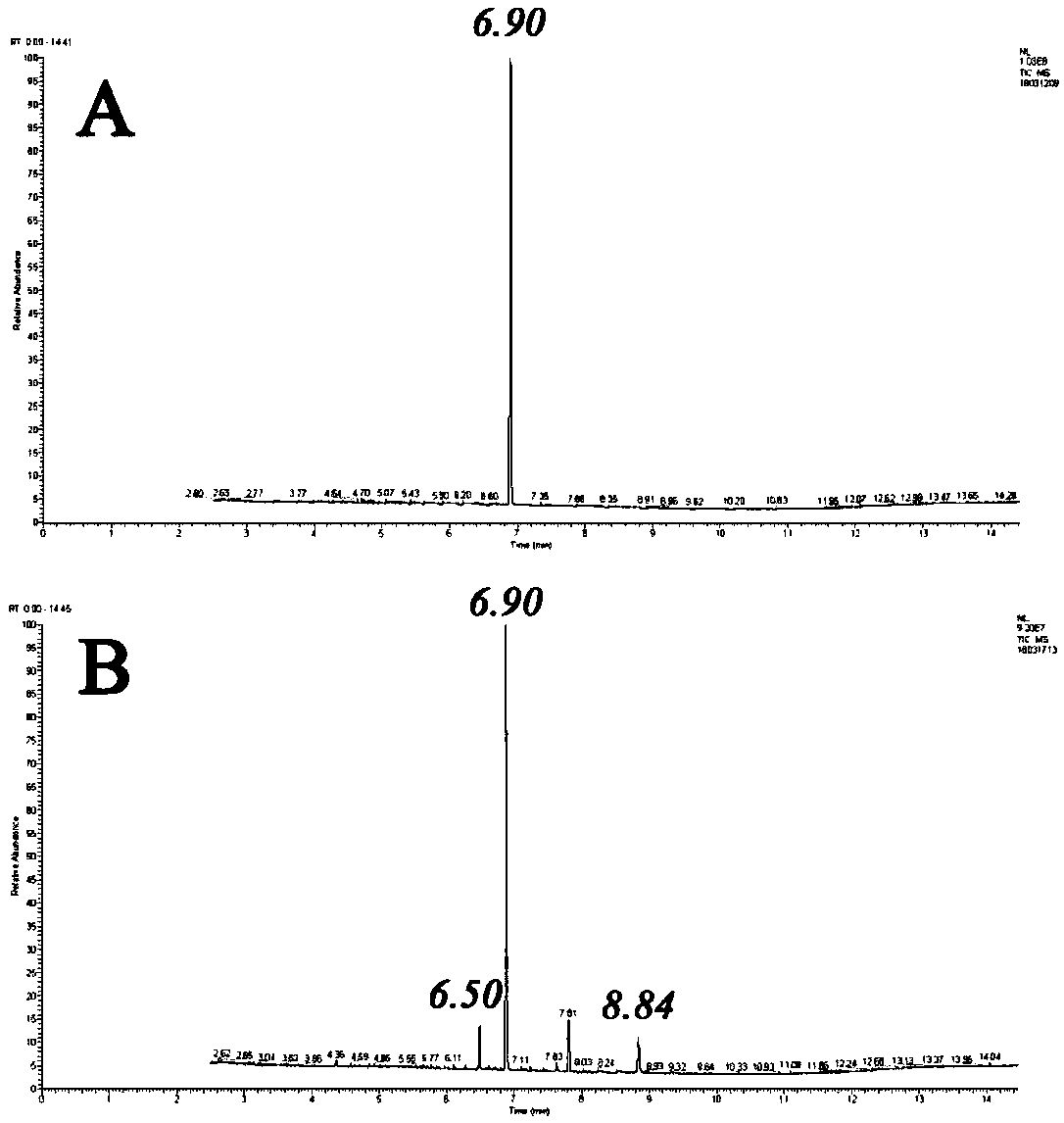

[0047] Such as figure 1 As indicated, the resulting solution was detected by gas chromatography-mass spectrometr...

Embodiment 2

[0050] 0.67mmol methyl levulinate, 0.1g Cu 2 (OH) 2 CO 3 / AlOOH (Cu / Al=3 / 1) and 20ml of isopropanol were placed in a 35mL autoclave. After the autoclave was sealed, the reaction was stirred at 180°C for 1h. After the autoclave was cooled, it was tested.

[0051] where Cu 2 (OH) 2 CO 3 The preparation method of / AlOOH catalyst is: with 3.624g Cu (NO 3 ) 2 ·3H 2 O and 1.875gAl 2 (NO 3 ) 3 9H 2 O was dissolved in 40 mL of deionized water and stirred at room temperature for several minutes; subsequently, with 1mol / L Na 2 CO 3 Adjust the pH of the solution to 8-9, stir for ten minutes, and let it stand overnight; then filter it with suction, wash it four or five times with deionized water, and dry it in an oven at 80°C; then grind it and bake it in a muffle furnace at 200°C. Finally, Cu with a Cu / Al molar ratio of 3 / 1 is obtained 2 (OH) 2 CO 3 / AlOOH.

[0052] The obtained solution was detected by gas chromatography-mass spectrometry (TRACE DSQ GC-MS). According t...

Embodiment 3

[0054] 0.67mmol methyl levulinate, 0.1g Cu 2 (OH) 2 CO 3 / AlOOH (Cu / Al=3 / 1) and 20ml of isopropanol were placed in a 35mL autoclave. After sealing the autoclave, the reaction was stirred and reacted at 180°C for 24h. After the autoclave was cooled, it was to be tested.

[0055] where Cu 2 (OH) 2 CO 3 The preparation method of / AlOOH catalyst is: with 3.624g Cu (NO 3 ) 2 ·3H 2 O and 1.875gAl 2 (NO 3 ) 3 9H 2 O was dissolved in 40 mL of deionized water and stirred at room temperature for several minutes; subsequently, with 1mol / L Na 2 CO 3 Adjust the pH of the solution to 8-9, stir for ten minutes, and let it stand overnight; then filter it with suction, wash it four or five times with deionized water, and dry it in an oven at 80°C; then grind it and bake it in a muffle furnace at 200°C. Finally, Cu with a Cu / Al molar ratio of 3 / 1 is obtained 2 (OH) 2 CO 3 / AlOOH.

[0056] The obtained solution was detected by gas chromatography-mass spectrometry (TRACE DSQ GC-M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com