Toothed disc type bottle cap detection device

A technology of bottle caps and toothed discs, which is applied in measuring devices, optical testing of flaws/defects, and material analysis through optical means. Contamination, effects on stable operation, and simplified detection steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

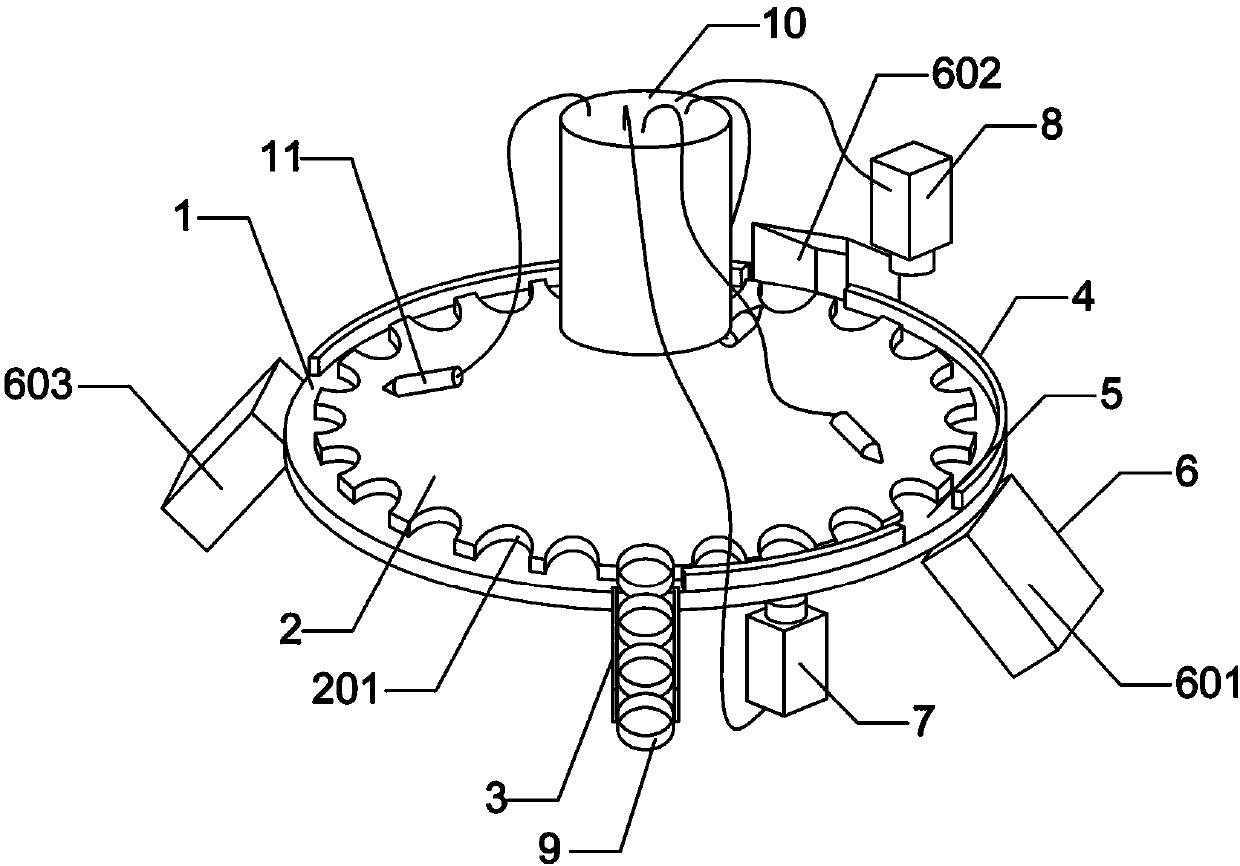

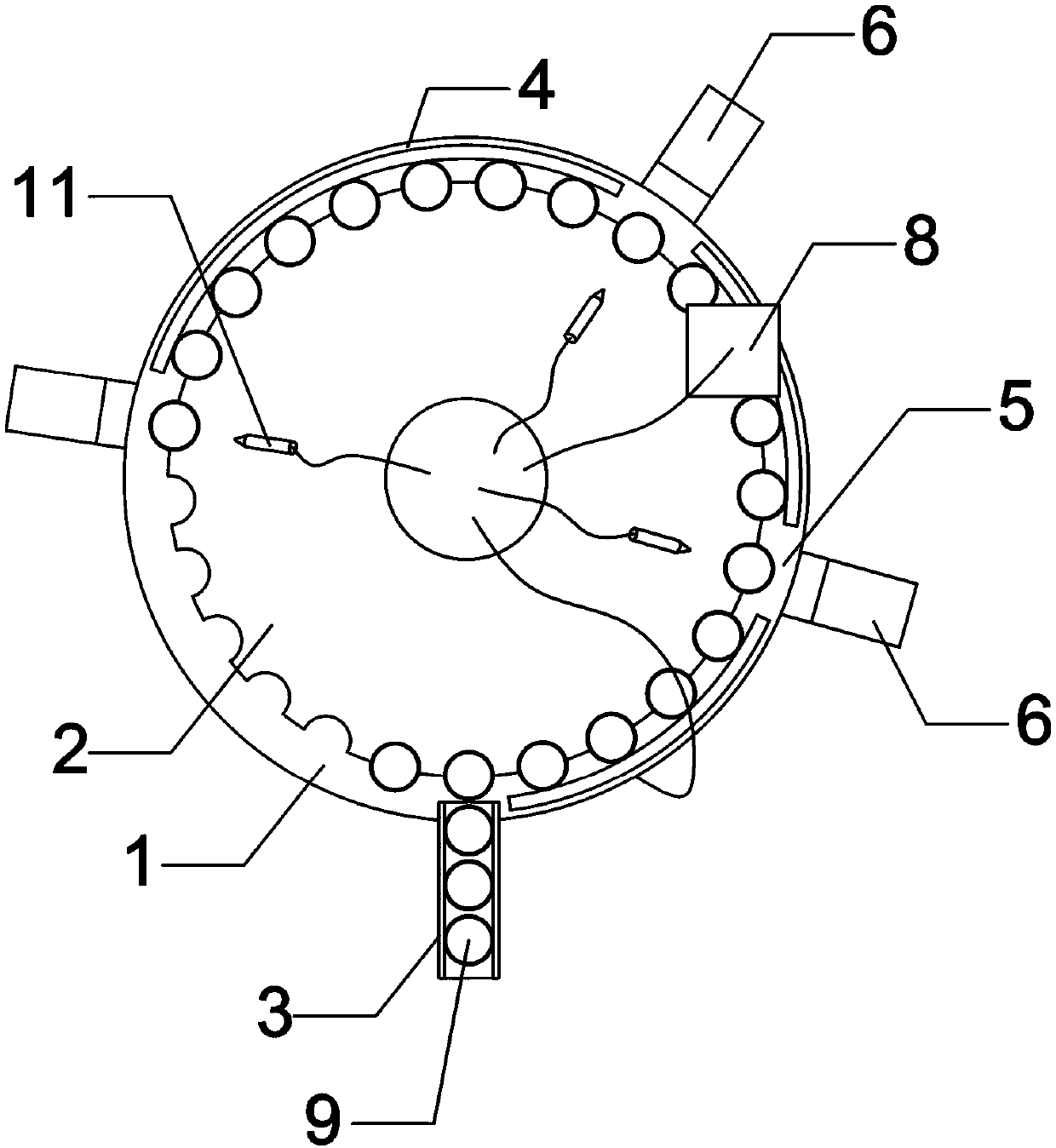

[0020] As shown in the figure, a toothed disc type bottle cap detection device includes a tray 1, a bottle cap limiting toothed plate 2 is arranged on the tray 1, and a bottle cap positioning gap 201 is uniformly provided on the outer side of the bottle cap limiting toothed plate 2. The cap limit tooth plate 2 can rotate axially on the tray, and the bottle cap input port 3 is set on the side of the tray 1;

[0021] A control system 10 is provided above the tray 1, and a blowing nozzle 11 is connected to the control system 10. A discharge port 6 is provided on the outside of the tray 1, and the blowing nozzle 11 is arranged in the direction of the discharge port 6.

[0022] In a preferred solution, the tray 1 is made of a transparent material, and a first image acquisition device 7 and a second image acquisition device 8 are respectively provided below and above the tray 1, the camera of the first image acquisition device 7 is vertically upward, and the second image acquisition ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com