Nanomaterial production device based on LICVD method

A technology of nanomaterials and production equipment, applied in chemical instruments and methods, chemical/physical/physicochemical processes using energy, chemical/physical/physicochemical processes, etc. The vacuum is not complete, the reaction environment is not clean enough, etc., to achieve the effects of reducing production costs, flexible structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

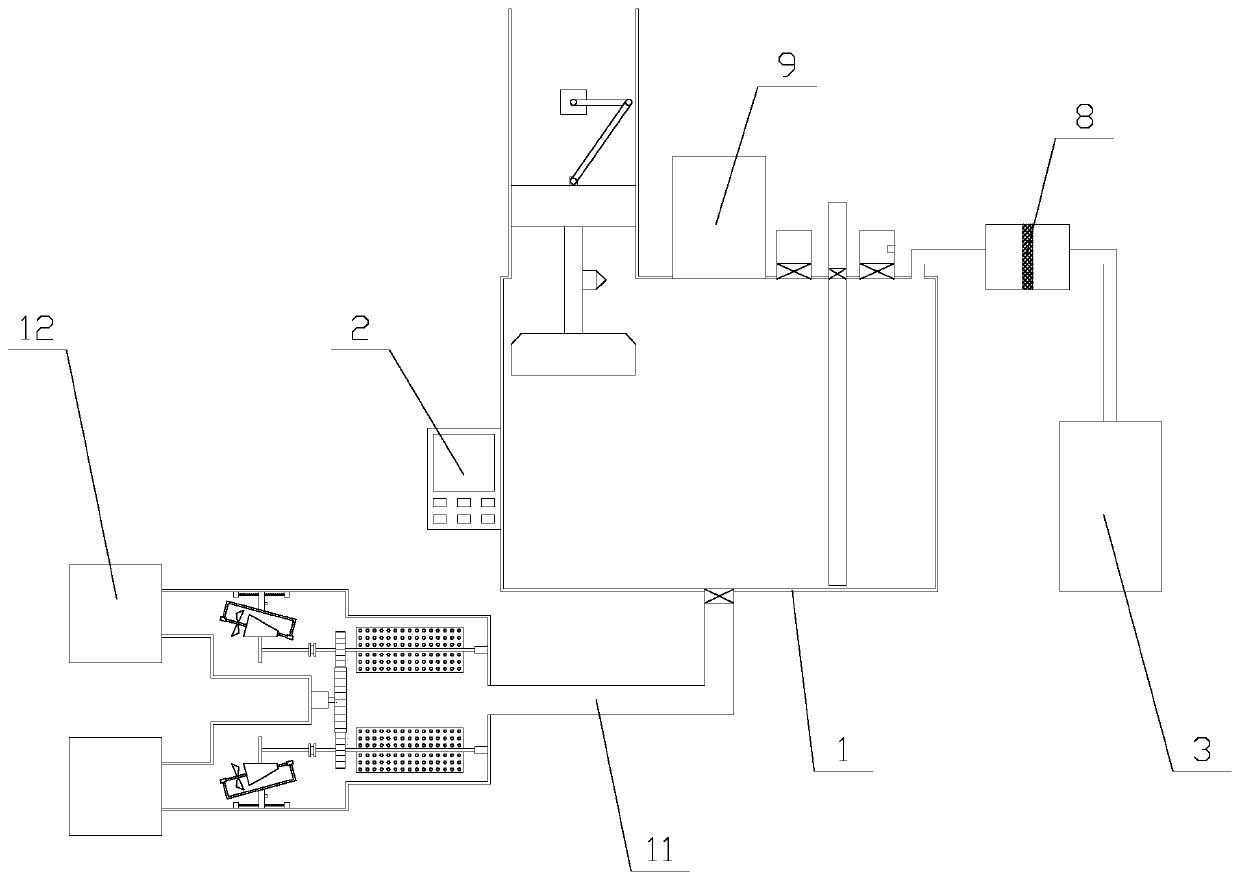

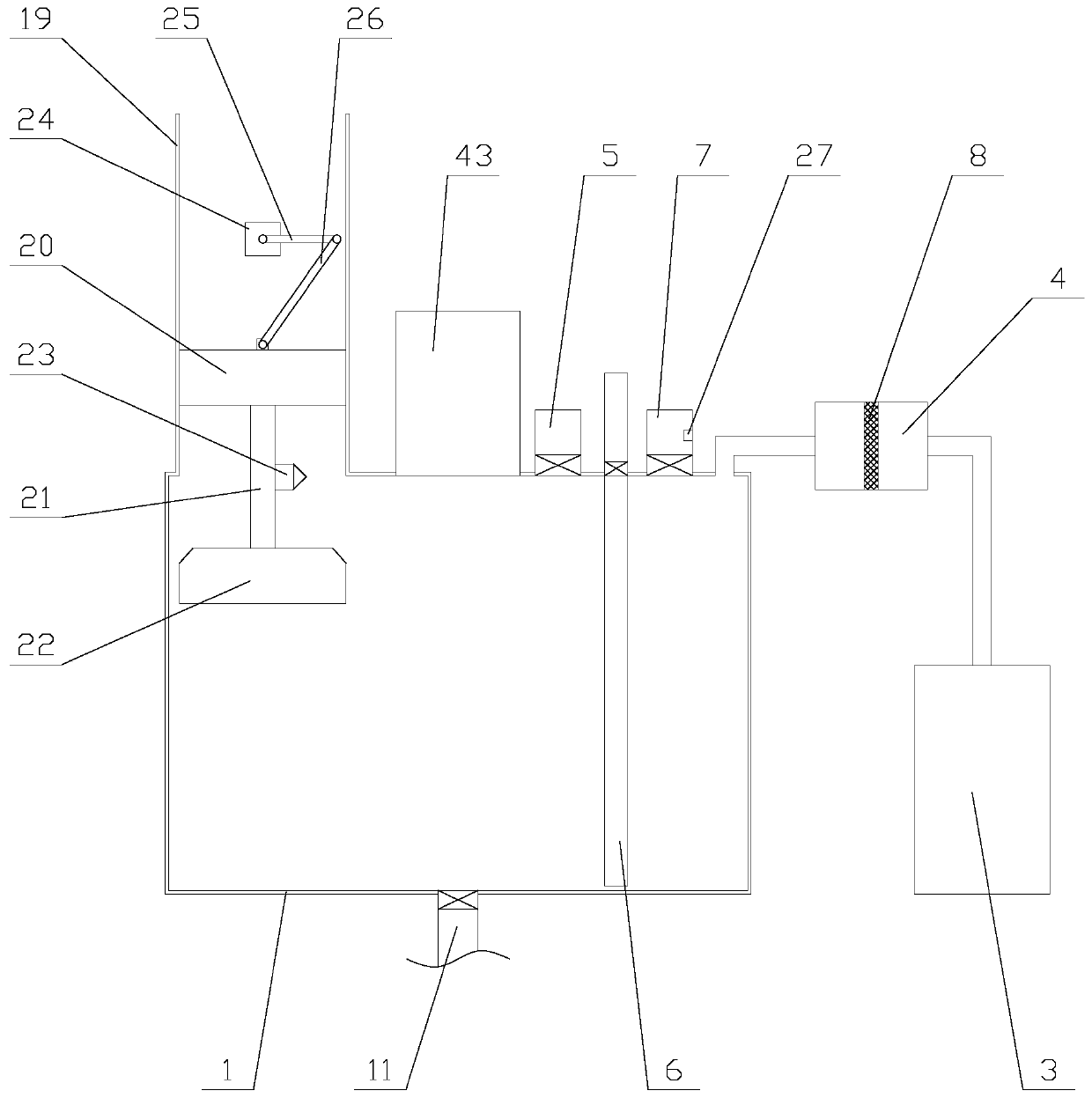

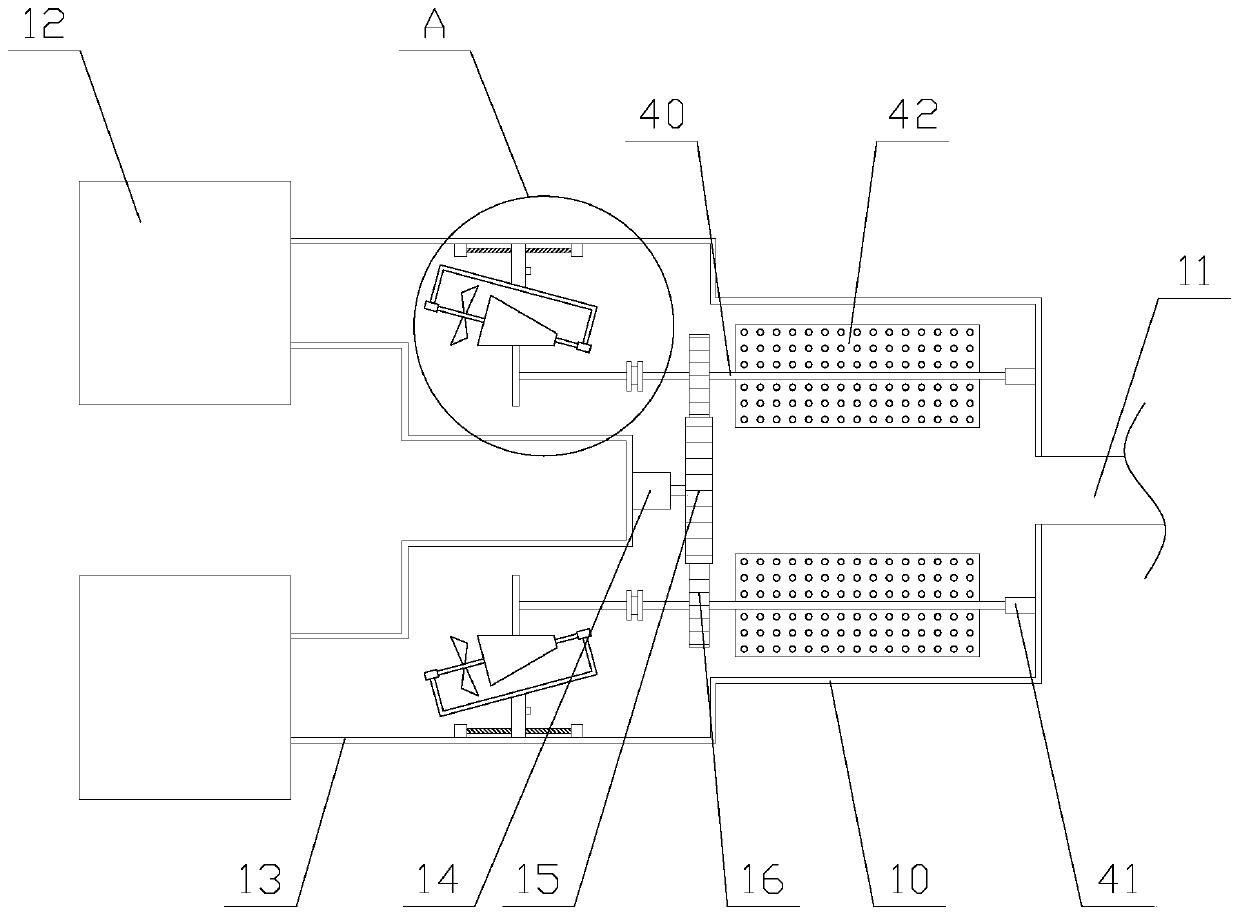

[0024] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0025] Such as figure 1 As shown, a nano-material production equipment based on LICVD method includes a reaction chamber 1, a controller 2, a gas supply mechanism, a cleaning mechanism, a trap 9 and an irradiation mechanism, and the controller 2 is fixed on a part of the reaction chamber 1. side, the gas supply mechanism is connected to the bottom of the reaction chamber 1, the irradiation mechanism is arranged above the reaction chamber 1, the trap 9 is fixed above the reaction chamber 1, and the cleaning mechanism is connected to the reaction chamber 1 , the controller 2 is provided with a PLC, and the trap 9 is electrically connected to the PLC;

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com