Handle assembly and garden tool equipped with the same

A garden tool and component technology, applied in the field of handle components and garden tools with the same, can solve problems such as engine vibration, large heat generation, and impact on service life of grass trimmers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

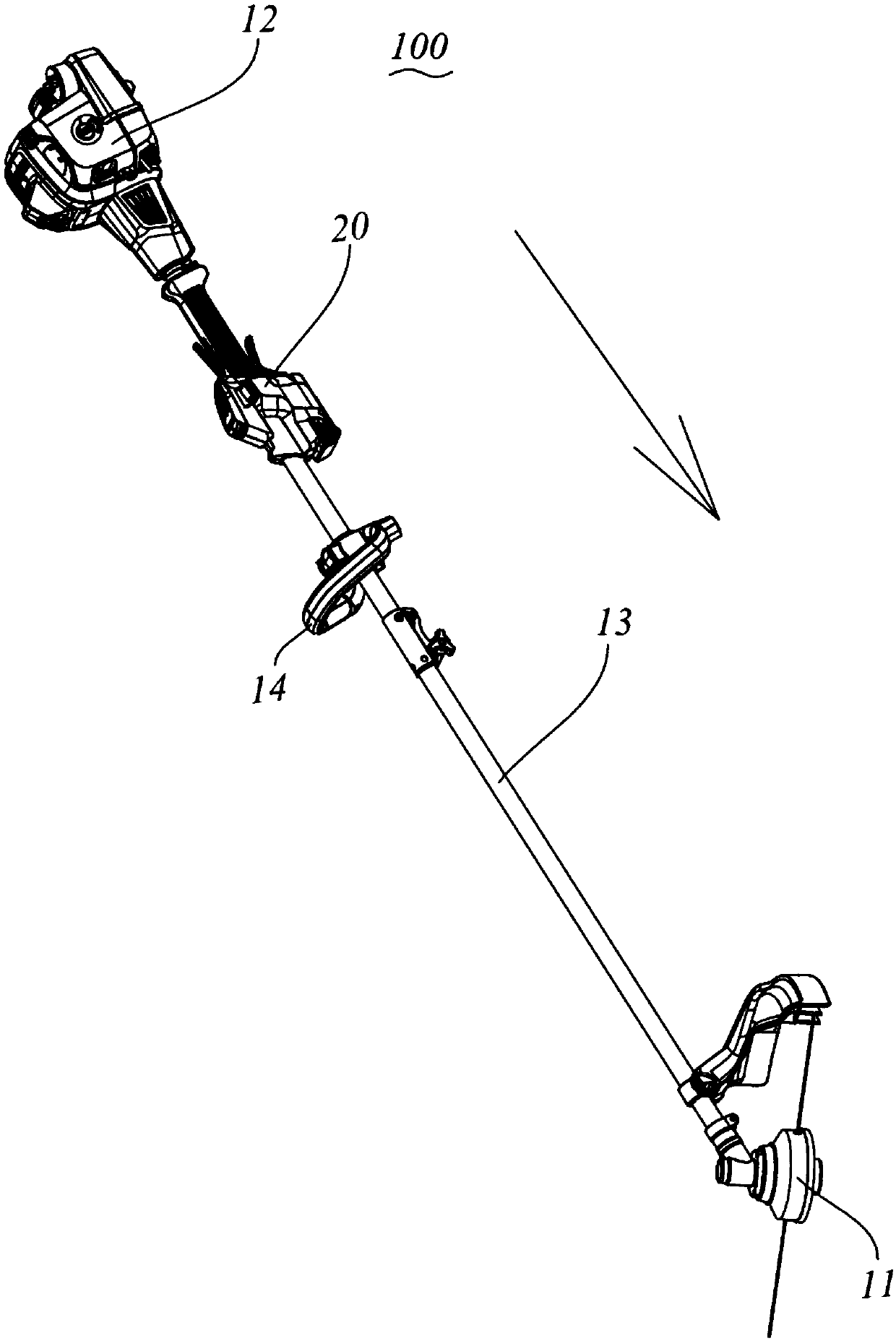

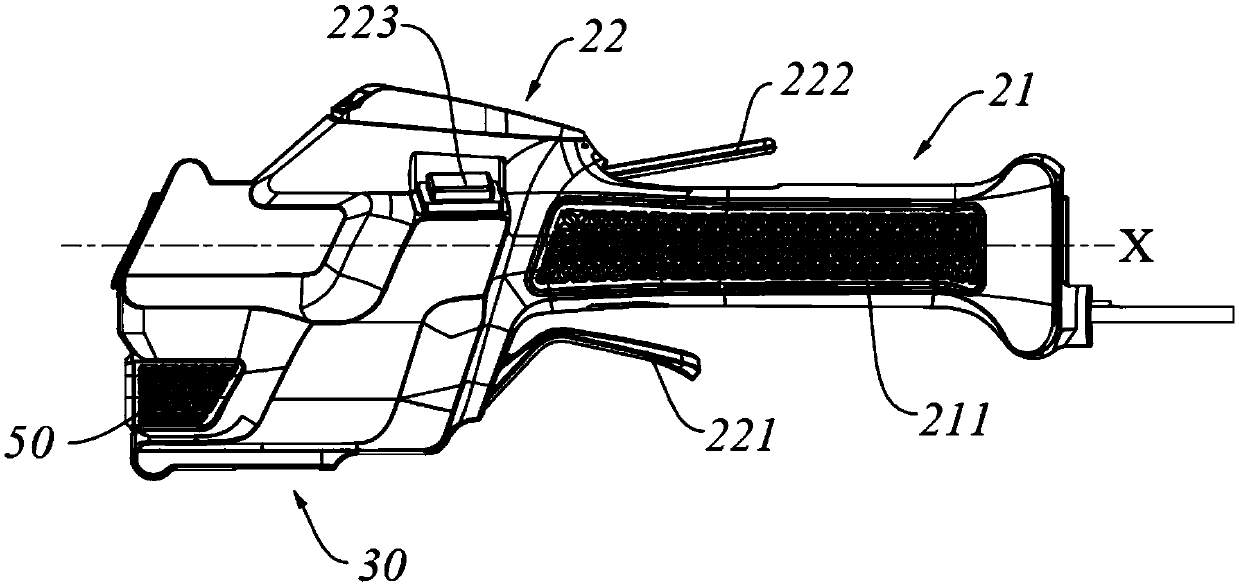

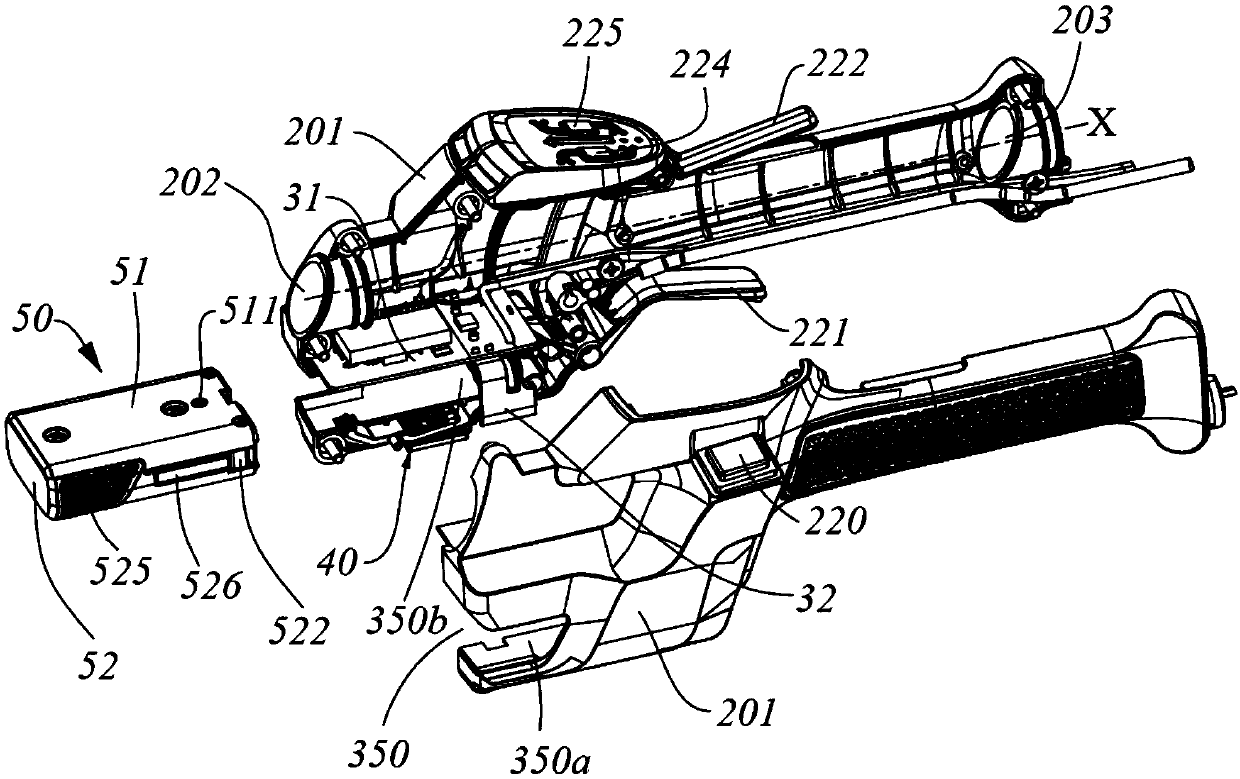

[0100] In this embodiment, a mower is taken as an example for specific description. refer to figure 1 As shown, the mower 100 includes a connecting rod assembly 13 , a working mechanism 11 connected to the front end of the connecting rod assembly 13 and a power mechanism 12 connected to the rear end of the connecting rod assembly 13 . Here, the front and rear ends are close to the area to be cut when operating the mower, and the back is the user holding or away from the cutting area. The direction shown by the arrow in the figure is the front. In this embodiment, the working mechanism 11 includes a casing, a cutting member disposed in the casing and rotating around an axis in a working plane, and a shield connected to the casing or the connecting rod assembly. The mowing machine in this embodiment includes a gasoline engine arranged in the power mechanism 12, and the gasoline engine provides power for the working mechanism 11. A starter motor is also provided in the power me...

Embodiment 2

[0116] Such as Figure 15-Figure 36 As shown, the present embodiment takes an electric start gasoline blowing machine as an example for description. In autumn, there are often a lot of scattered leaves outdoors, which brings many problems to the environment of the courtyard of the house. Especially after it rains, the leaves are mixed with muddy water and stick to the ground, which brings great trouble to cleaning. The electric start gasoline blower of this embodiment is the equipment that can clean garden or surrounding environment, and its working principle is to start the engine of gasoline engine by battery operation, and engine impels crankshaft to rotate at high speed and drives impeller to rotate, thereby produces suction or blows, realizes The purpose of cleaning.

[0117] Specifically, such as Figure 15 and Figure 16 As shown, the air blower 700 includes a body 701, on which a working mechanism and a power mechanism are arranged, wherein the working mechanism inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com