Packing sealing mechanism of motor in medium and small-scale electric appliance

A sealing mechanism, small and medium-sized technology, used in electrical components, electromechanical devices, electric components, etc., can solve problems such as high working noise, and achieve the effects of increasing service life, strong noise absorption and noise reduction, and slowing elastic attenuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Below in conjunction with the accompanying drawings, the specific embodiments of the present invention will be further described in detail, so as to make the technical solution of the present invention easier to understand and grasp.

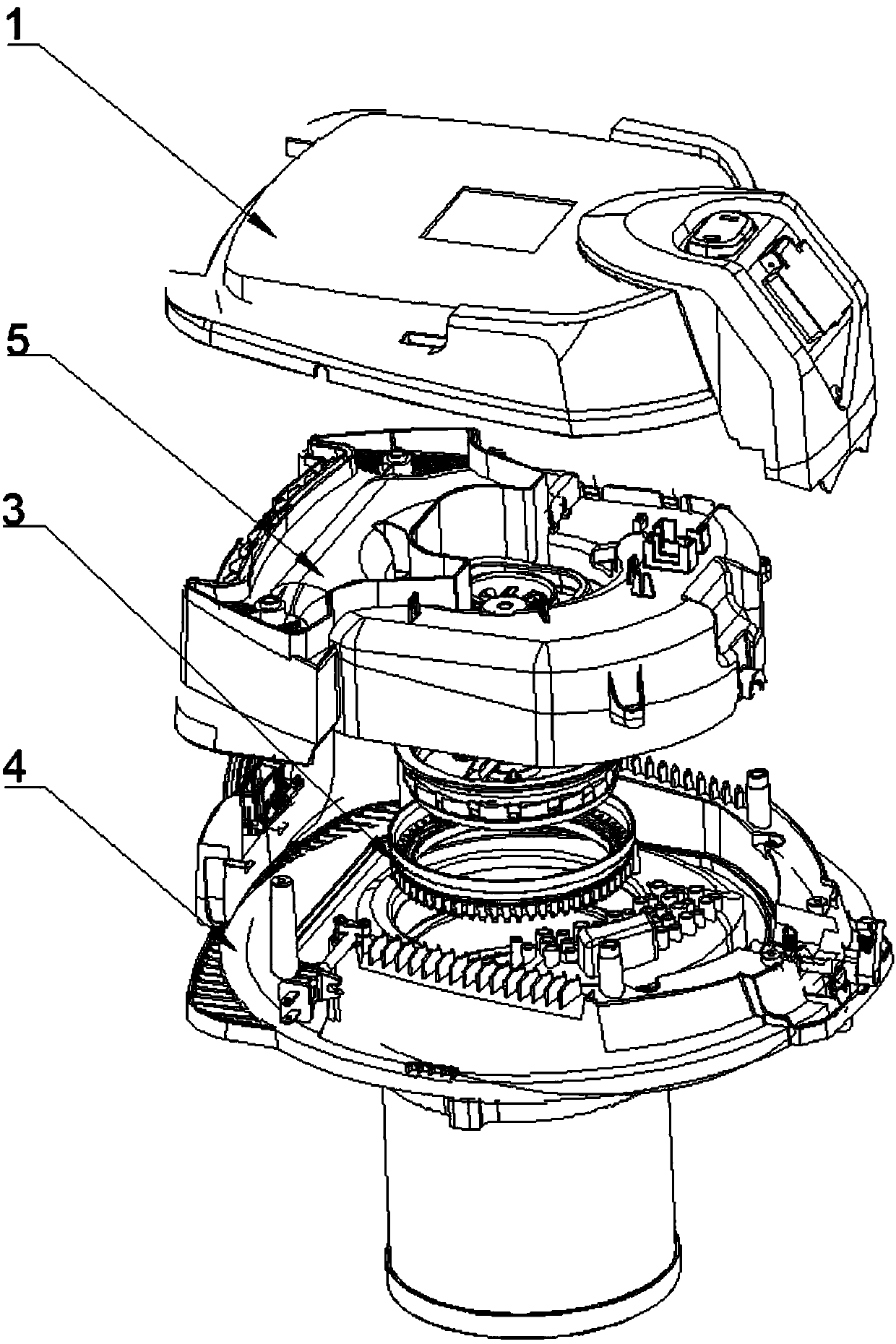

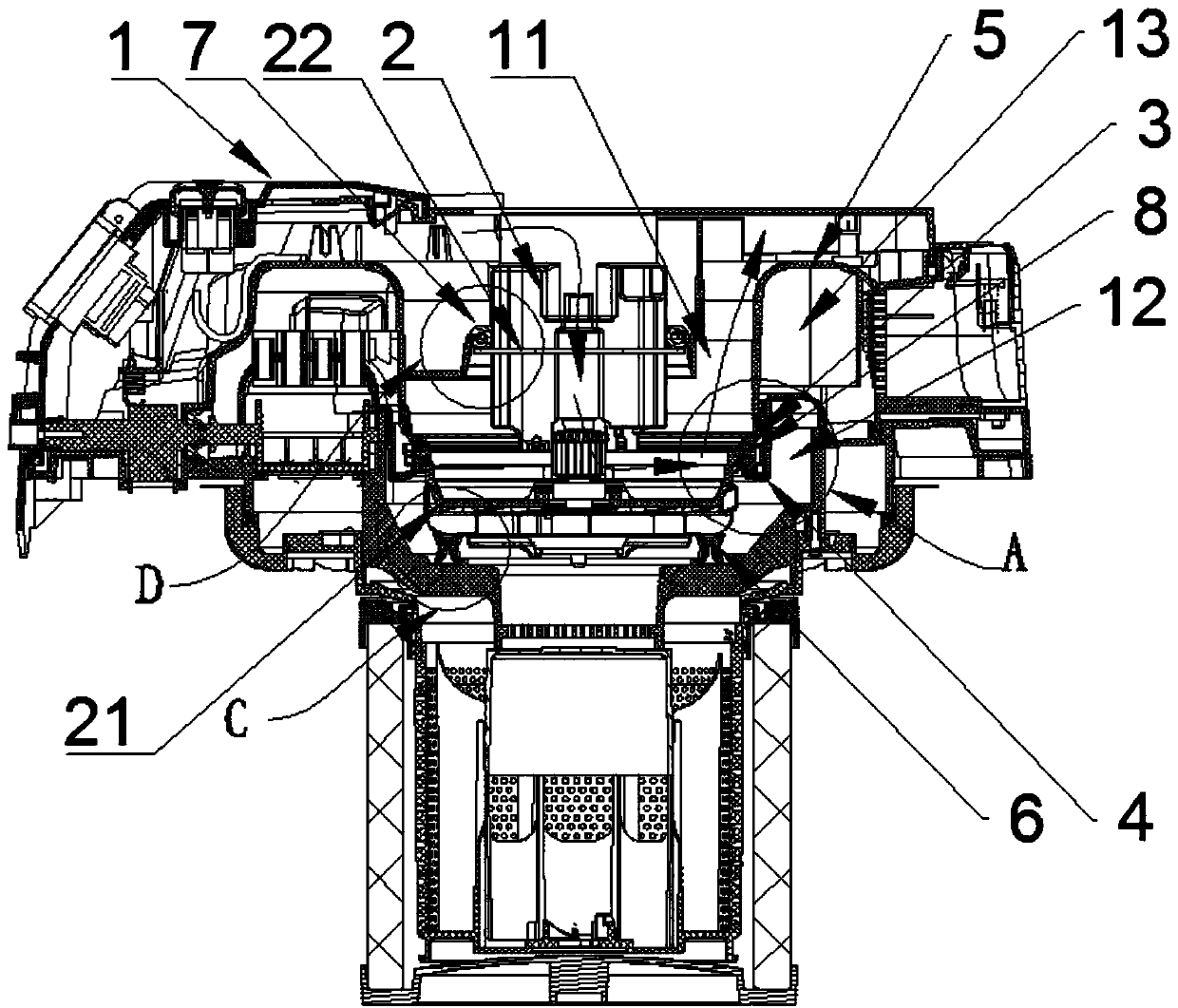

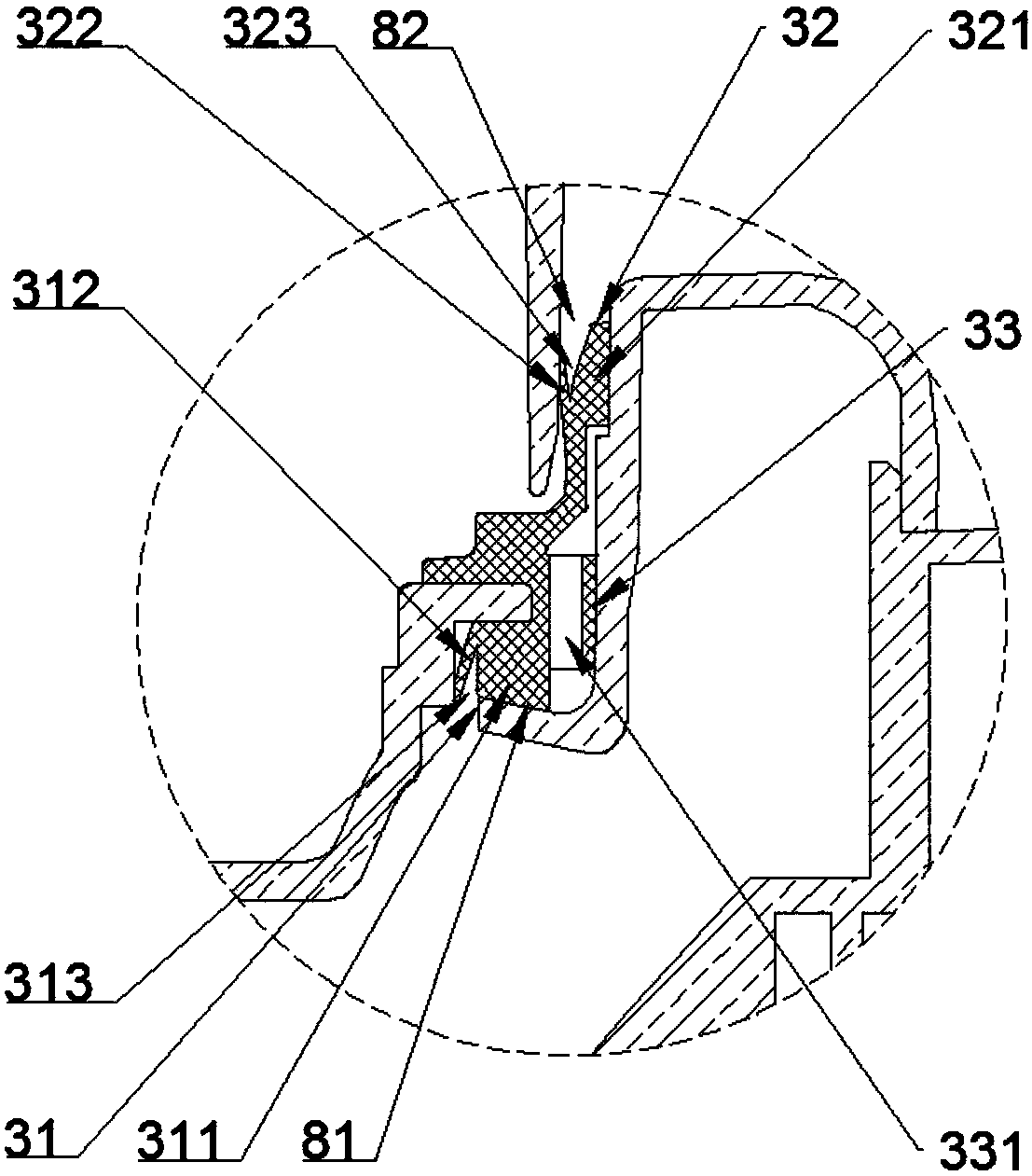

[0045] The invention provides a sealing mechanism for motors in small and medium-sized electrical appliances, such as Figure 7 As shown, the casing 1 is provided with a lower cover 10 for supporting the motor base 21, and a flexible sealing bottom sealing ring 6 is provided between the lower cover 10 and the motor base 21. It should be noted that the lower cover 10 is isolated from the first The cover 4 can be an independent material or an integrated material. The materials of the two are the same or different. More preferably, the bottom of the motor base 21 has an impeller cavity cover 9, and an impeller is formed between the impeller cavity cover 9 and the motor base 21. The chamber 91 and the bottom sealing ring 6 are arranged betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com