Yarns with conductive elastomeric cores,fabrics and garments formed of the same,and methods for producing the same

A technology of conductive yarn and conductive parts, applied in the field of yarn and yarn manufacturing, can solve problems such as fabrics where yarn is not suitable for clothing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

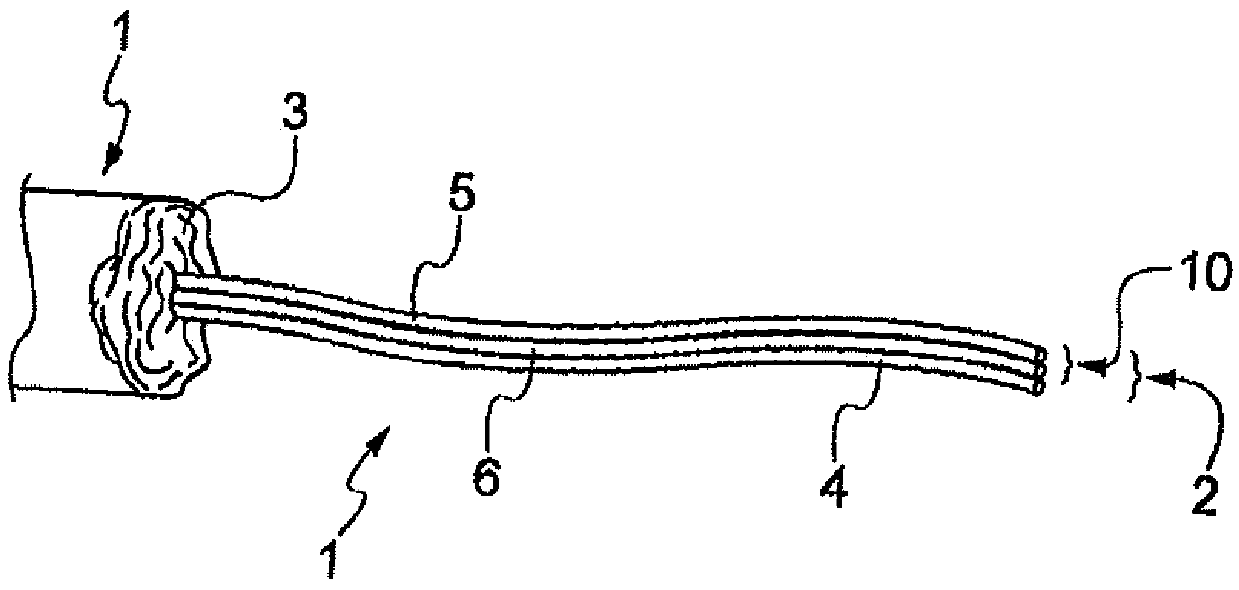

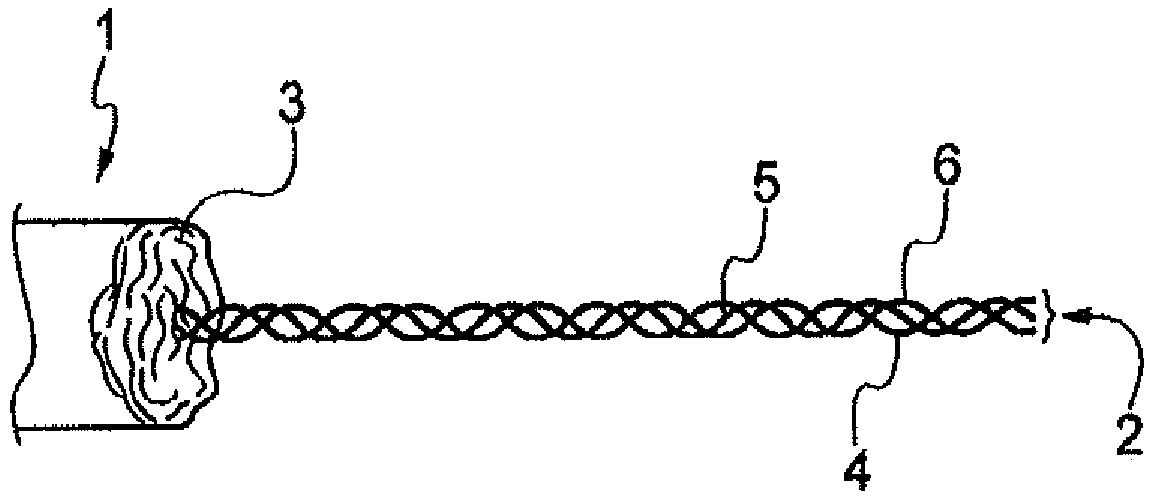

[0021] The present disclosure relates to conductive elastic yarns and the use of various yarn manufacturing processes to make such yarns. The conductive elastic yarn includes a conductive core of one or more elastic fibers and an insulating sheath covering the conductive core. Conductive elastic yarns are used to fabricate stretchable conductive fabrics for various sensing applications in various types of clothing and other wearable appliances and devices. Conductive elastic yarns can be used in both warp and fill directions in woven and knitted fabric construction. Garments formed from stretchable conductive fabrics include various types of shirts, pants, bodysuits, hats, shorts, socks, and various other types of garments. Stretchable conductive fabrics can also be used to form sleeves, tights, or various bands or other implements or devices that are worn at various locations on the wearer's body.

[0022] Stretchable conductive fabrics form sensing devices and are coupled ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com