Non-aqueous electrolyte of high-temperature resistant lithium ion battery

A lithium-ion battery and non-aqueous electrolyte technology, applied in the field of lithium-ion batteries, can solve problems such as the limit temperature that cannot be commercialized, and achieve the effects of improving long-term cycle performance, reducing reaction, and reducing gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Electrolyte solution preparation steps: In a glove box filled with argon, mix ethylene carbonate, propylene carbonate and diethyl carbonate according to the mass ratio of EC:PC:DEC=40:5:55, and then slowly pour into the mixed solution Add 12.5wt% lithium hexafluorophosphate, finally add 1.0wt% vinylene carbonate (VC) based on the total weight of the electrolyte, and 3.5wt% 1,3-propane sultone (1,3-PS) based on the total weight of the electrolyte ), based on the vinyl ethylene carbonate (VEC) of 0.5wt% of the total weight of the electrolyte, the lithium-ion battery electrolyte of Example 1 was obtained after stirring.

[0033] The prepared lithium-ion power battery electrolyte was injected into the fully dried artificial graphite material / lithium cobaltate (4.2V) battery, and after the battery was left at 45°C, formed by high-temperature fixtures and sealed twice, it was routinely divided.

Embodiment 1-10

[0034] Embodiment 1-10 and comparative example 1-5

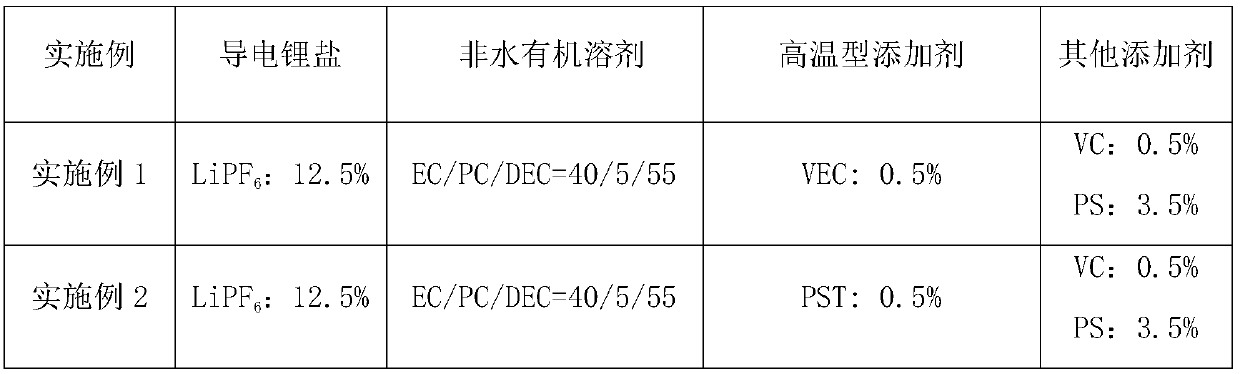

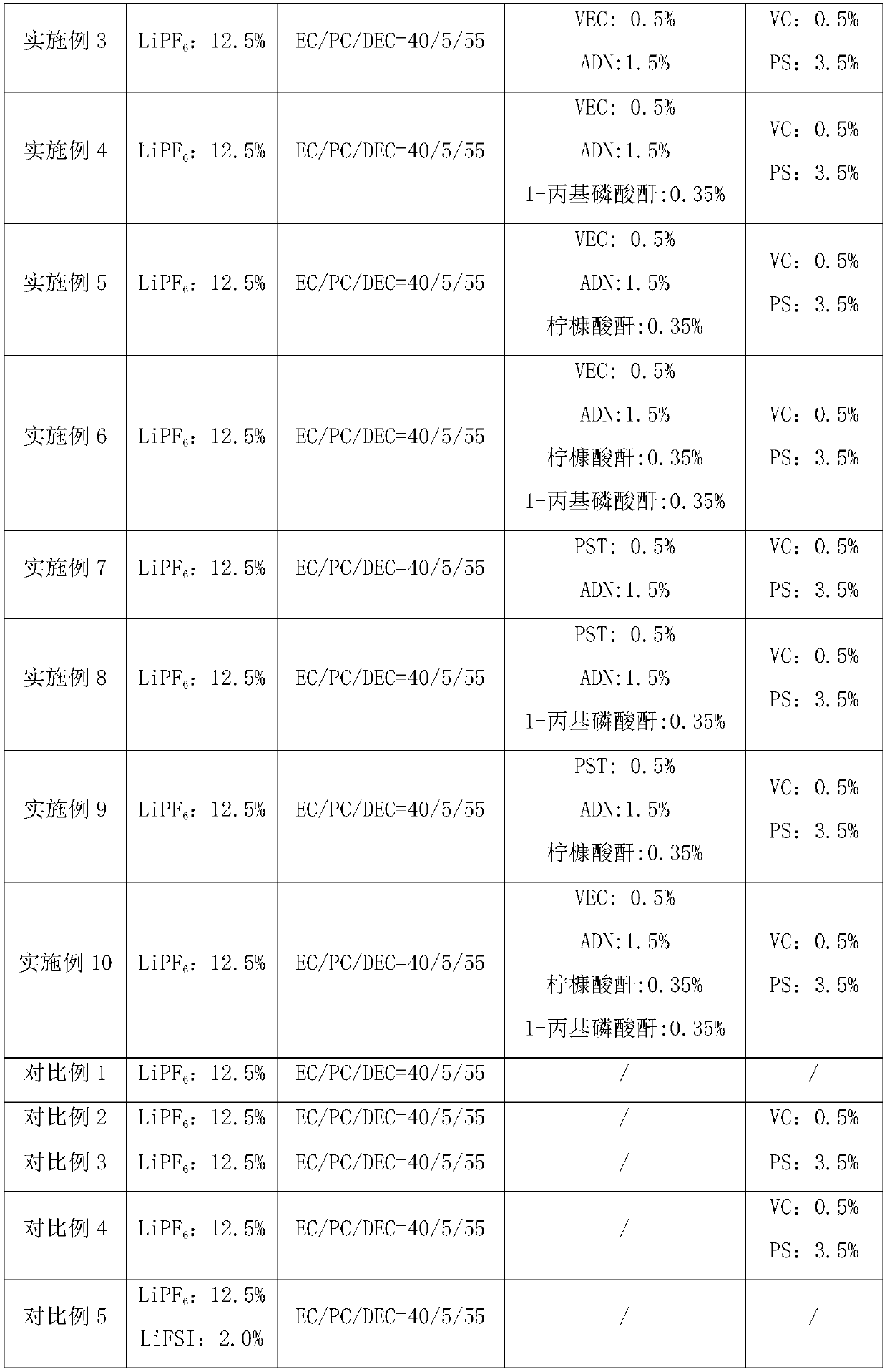

[0035] As shown in Table 1, in Examples 2-10 and Comparative Examples 1-5, except that the composition ratio of the components of the electrolyte solution is added as shown in Table 1, the others are the same as in Example 1.

[0036] Table 1 Embodiment 1-10 and the composition and proportioning ratio of the electrolyte of comparative examples 1-5

[0037]

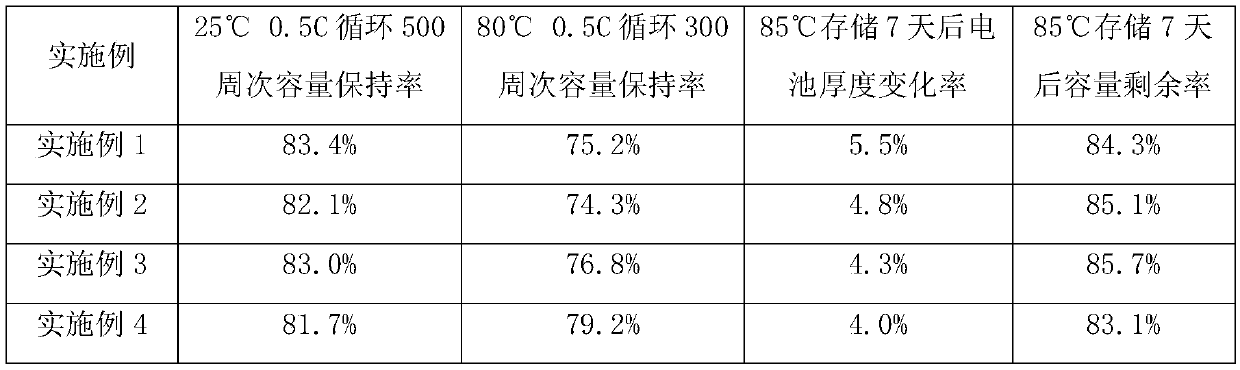

[0038]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com