Optical fiber coupler

A fiber coupler and fiber bundle technology, which is applied in the coupling of optical waveguides, lasers, and laser parts, etc., can solve the problems of difficulty in mass production and cost reduction, large volume, and limited increase in output power, and achieve functional diversification. , Simple structure, reasonable design effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

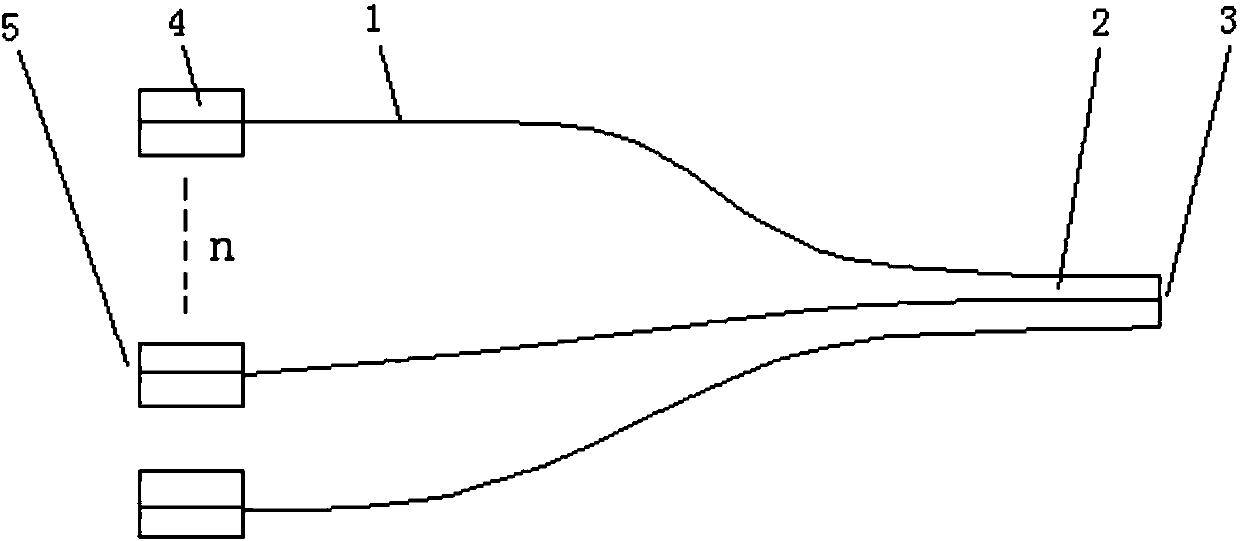

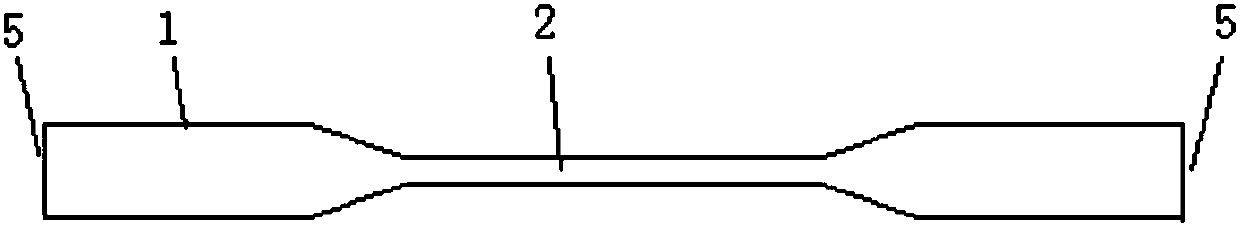

[0029] Such as image 3 or Figure 4 As shown, the present invention uses 20 20x400um 2 Of rectangular fibers are stacked closely together to form 400x400um 2 Large rectangular fiber bundle, and then form 100x100um in the middle of the fiber bundle by fusion tapering process 2 Or Φ100um 2 Finally, the fusion tapering part is cut to obtain two optical fiber couplers. The cut surface formed by cutting is used as the output end 3 of the optical fiber coupler, and the two ends of the 20 rectangular optical fibers are used as the two optical fibers The input of the coupler.

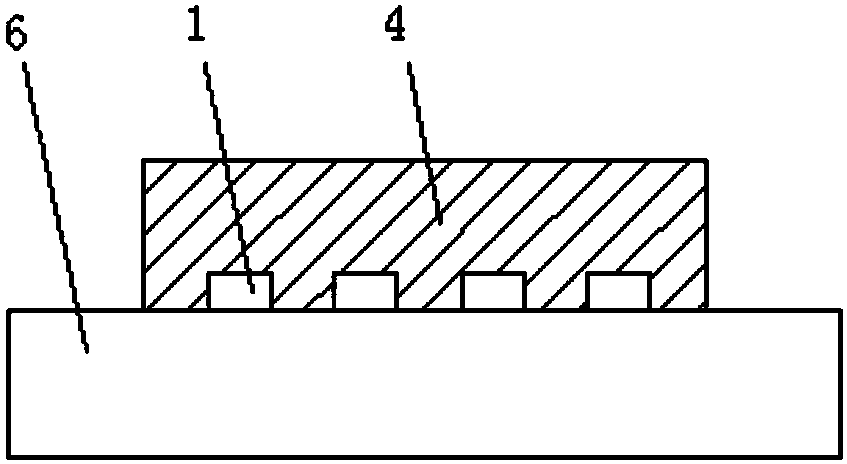

[0030] When 20 rectangular optical fibers are stacked, the optical fiber bundle is fixed by the mold 4.

[0031] As a structure of the mold 4, the mold 4 has a rectangular groove array for pressing down and fixing the optical fiber; when in use, 20 rectangular optical fibers can be placed on a flat carrier 6 such as flat glass, and then two molds 4 are used. The two ends of the rectangular slot array are pressed an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com