A method for measuring the thickness of the thin layer of heat and mass transfer on the surface of wood during the drying process

A wood surface, heat and mass transfer technology, applied in the field of wood drying treatment, measuring the thickness of wood surface heat and mass transfer thin layer in the process of wood drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

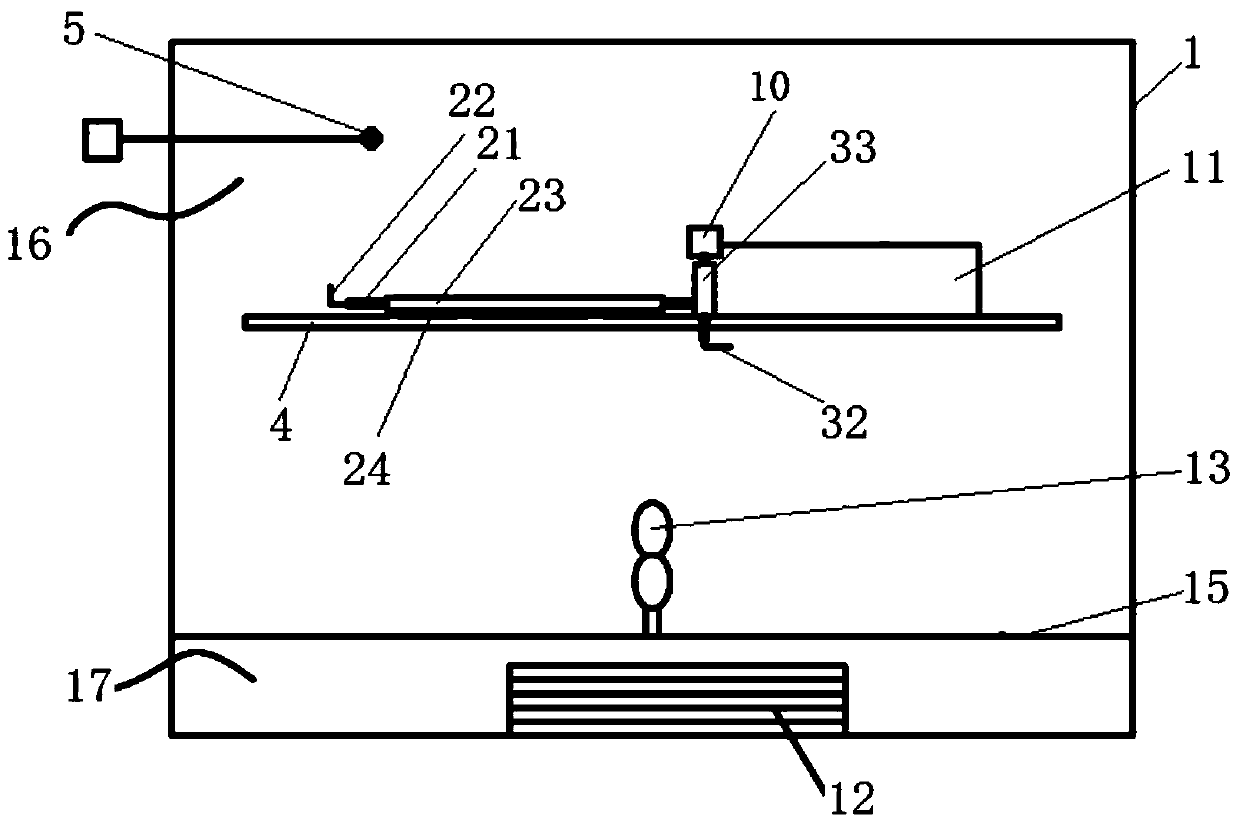

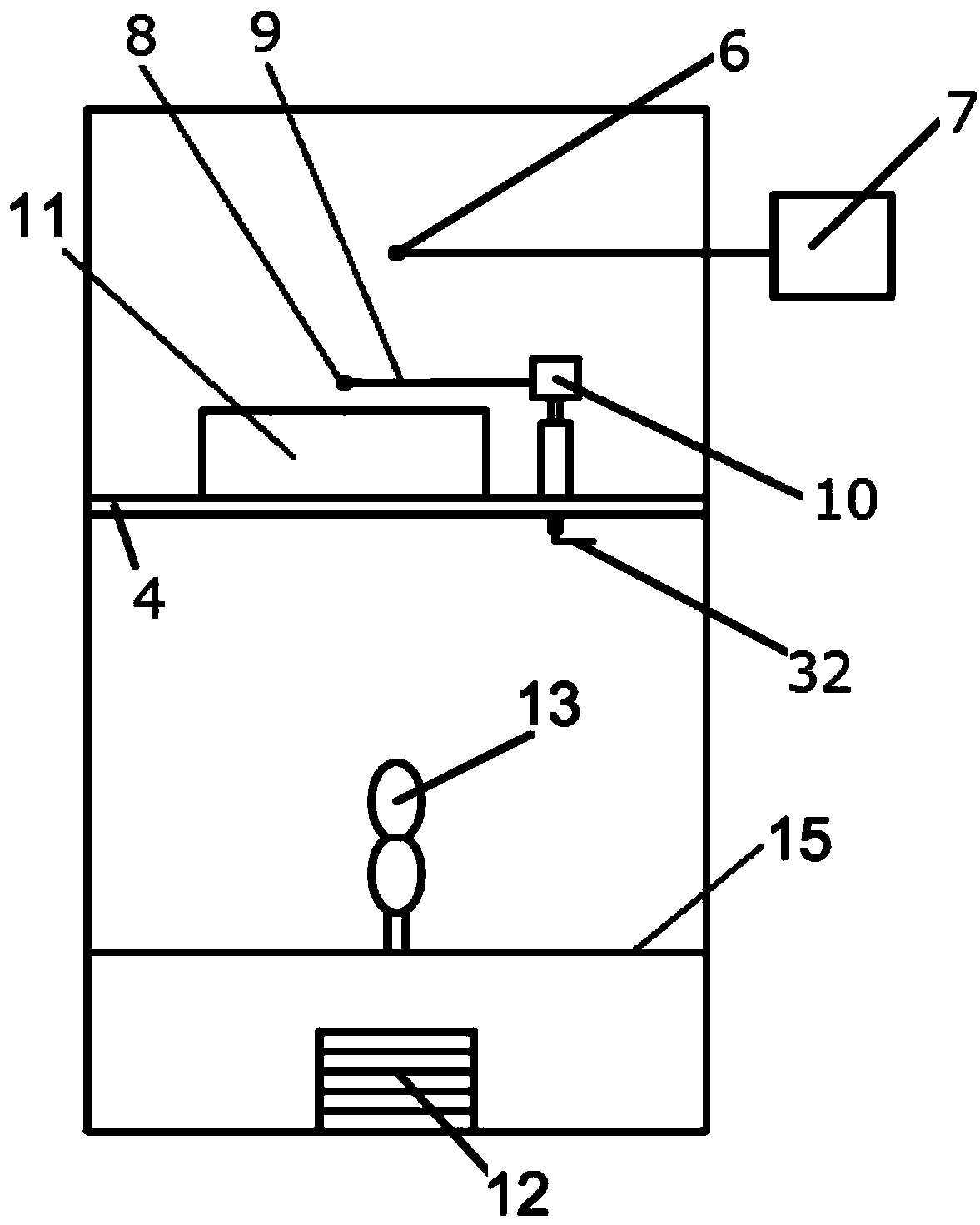

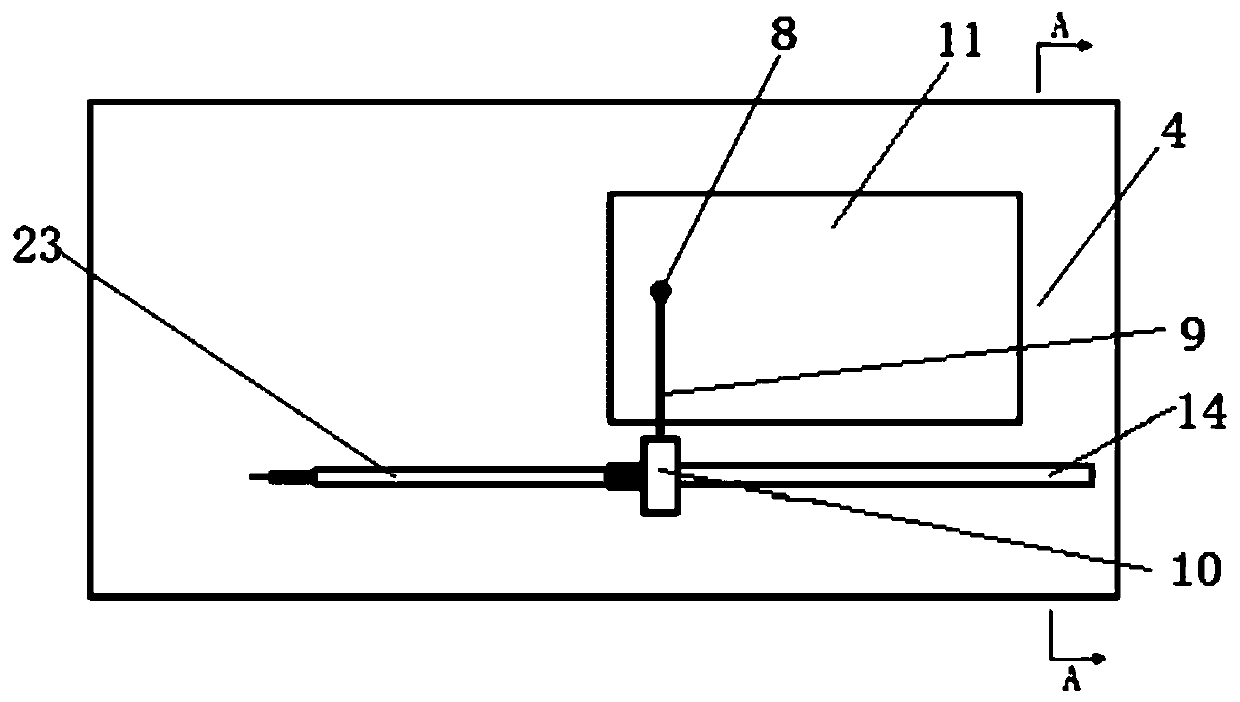

[0159]Using the device for measuring the thickness of the wood surface heat and mass transfer thin layer of the present invention, the poplar board with a length of 1.8m is dried under the condition that the dry bulb temperature of the medium is 60°C and the flow rate is 2m / s. Driven by the fan, the air inlet end is on the left side of the wood, and the air outlet end is on the right side of the wood, that is, the medium moves along the wood surface from Figure 8 The left side enters, flows through the wood surface, flows out from the right side, and circulates along the longitudinal direction of the drying room as an example.

[0160] Determination of the heat and mass transfer thin layer thickness at different positions on the wood surface, the specific method is as follows:

[0161] 1. If Figure 7 , 8 , a poplar plank with a length of 1.8m is placed on the upper part of the support, and the length and width of the wood are respectively consistent with the longitudinal d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com