Concrete equipment vehicle-mounted water tank heating device

A heating device and concrete technology, which is applied in lighting and heating equipment, solar heating systems, solar heat storage, etc., can solve the problems of reduced cleaning efficiency, easy cooling, and inability to heat the water in the vehicle tank, achieving multi-practicability and functional effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

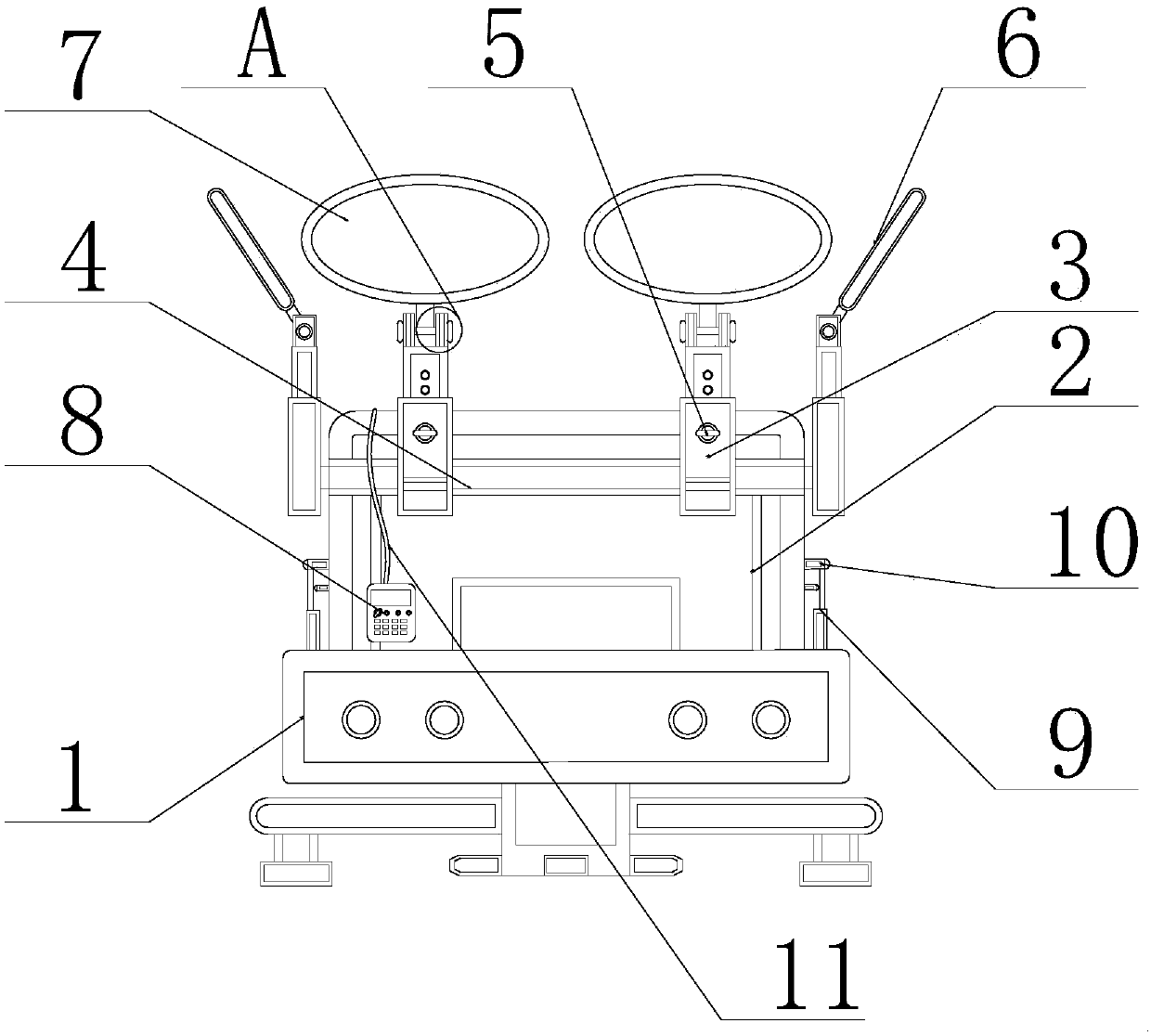

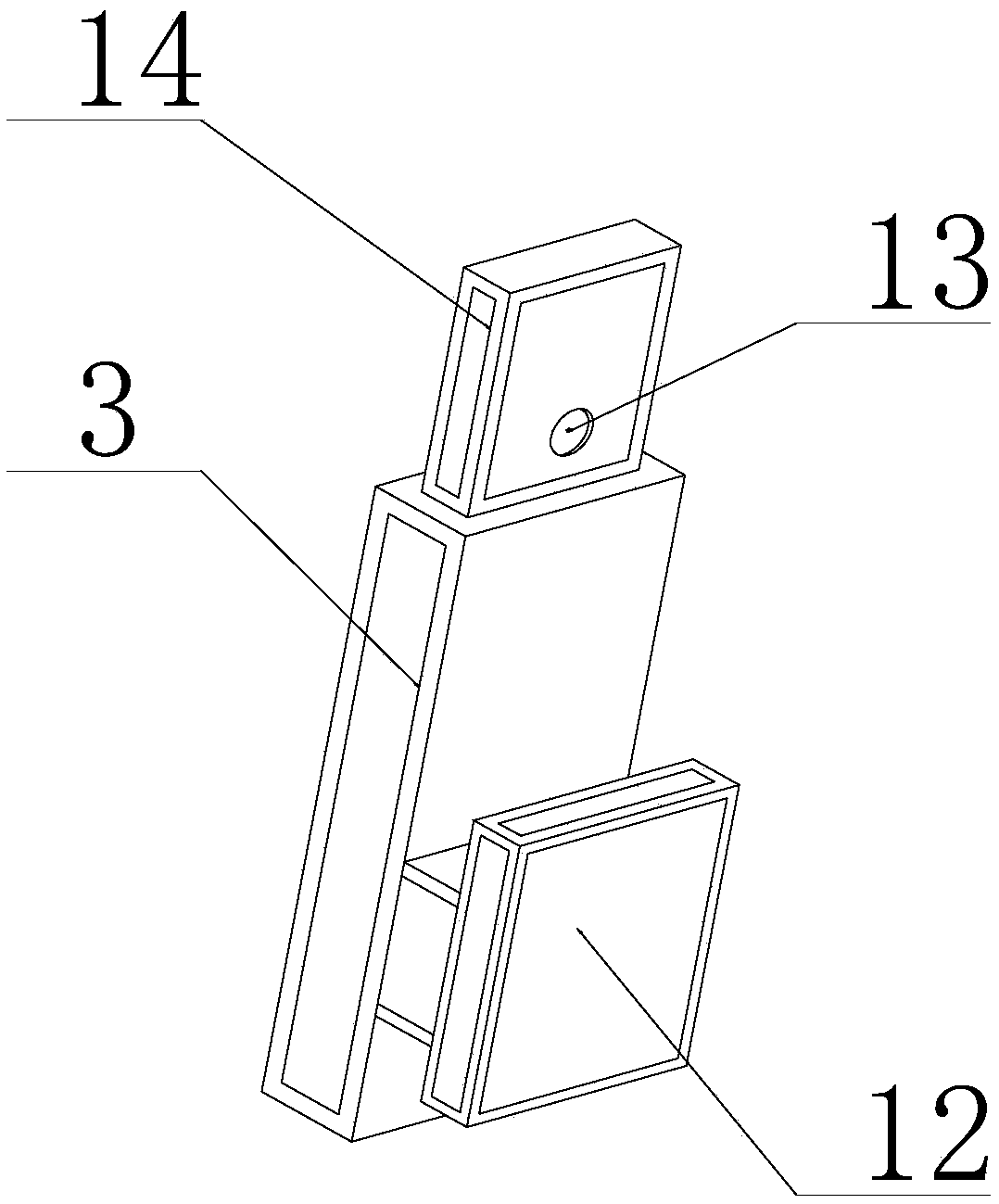

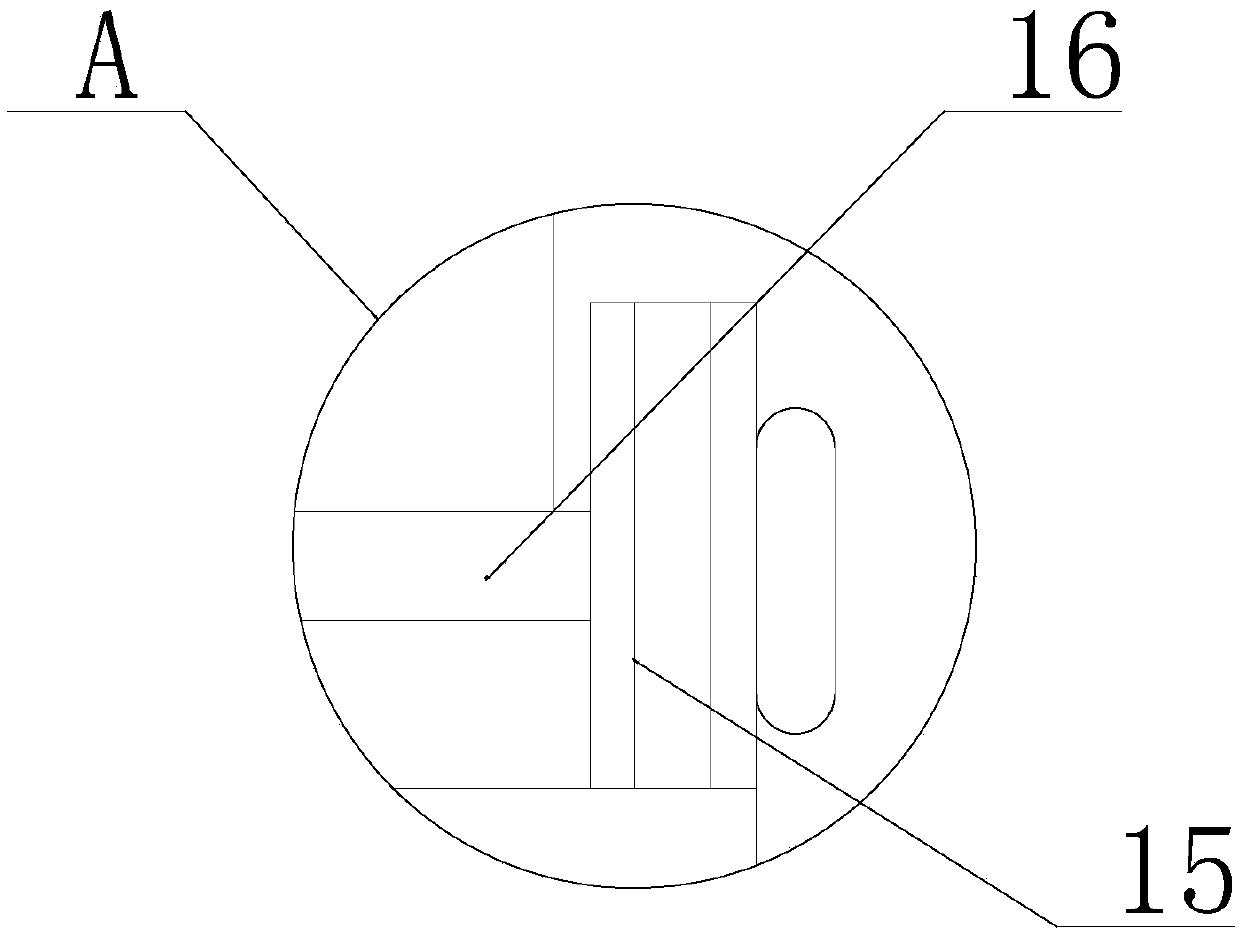

[0022] see Figure 1-5 , the present invention provides the following technical solutions: a vehicle-mounted water tank heating device for concrete equipment, comprising a second water storage case 2, a chute 4 is opened on the surface of the second water storage case 2, and one side of the second water storage case 2 A slider 3 is provided, one end of the slider 3 is integrally formed with a clamping block 12, the slider 3 is engaged in the chute 4 through the clamping block 12, and an engaging block 14 is arranged above the sliding block 3, and on the surface of the engaging block 14 A plurality of holes 13 are distributed, and a knob 5 is arranged on the surface of the slider 3, and the connecting block 14 is fixedly connected with the slider 3 through the holes 13 and the knob 5, and fixed blocks 15 are welded on both sides of the upper surface of the connecting block 14, and the two A rotating rod 16 is connected between the two fixed blocks 15, and a reflective disk 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com