Tension lifter for doubling and twisting machine

A lifting frame and twisting machine technology, applied in the direction of textiles and papermaking, etc., can solve the problems that the yarn diameter of the de-spun yarn cannot be too large, the yarn tension is uneven, and the phenomenon of loops, etc., to achieve convenient and quick installation and replacement , Balanced yarn feeding tension and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

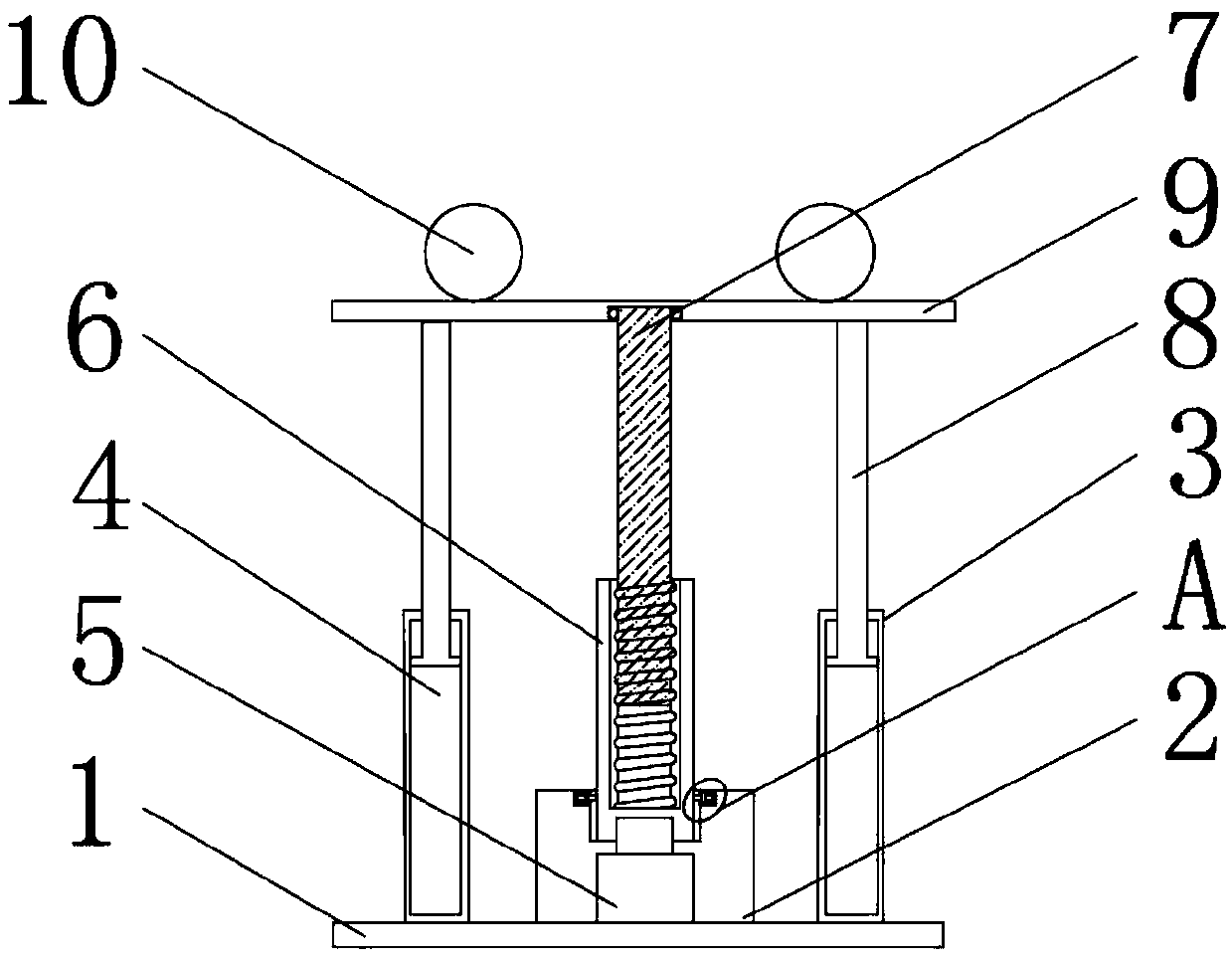

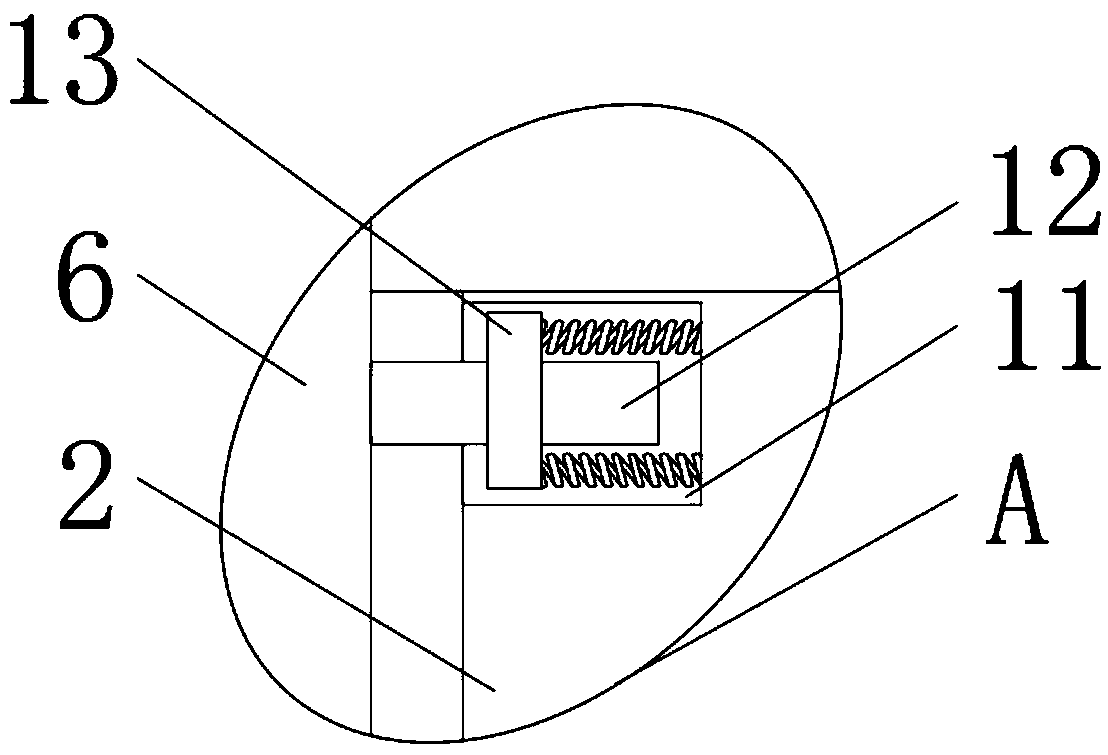

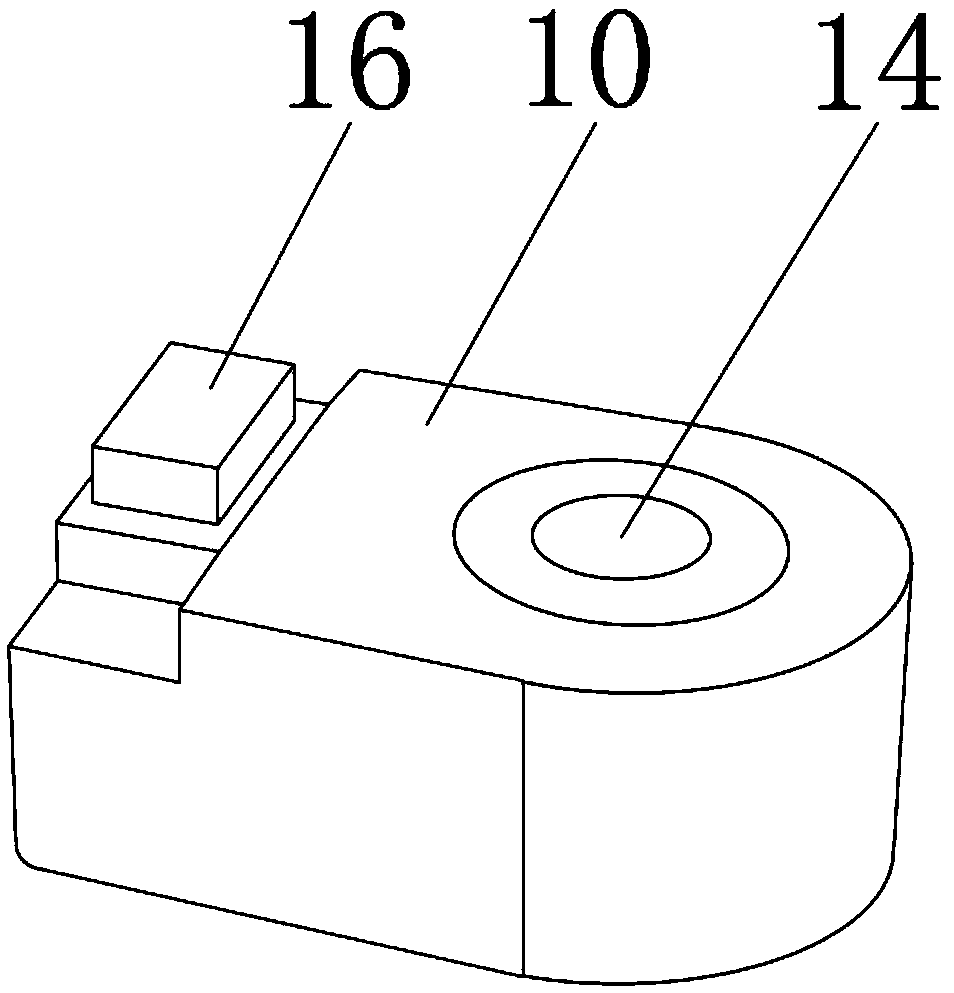

[0030] refer to Figure 1-2 As shown, a tension lifting frame of a twisting machine includes an upper end plate 1 of the primary twisting cylinder, a support frame 2 is welded at the center of the top outer surface of the upper end plate 1 of the primary twisting cylinder, and the top outer surface of the upper end plate 1 of the primary twisting cylinder is close to the support The position of the frame 2 is welded with four limit frames 3, and the four limit frames 3 are equidistantly distributed, the inside of the limit frame 3 is provided with a limit groove 4, and the inner center of the support frame 2 is fixed by bolts. Motor 5, and the top outer surface of motor 5 is fixedly installed with rotating drum 6, and the inner surface of rotating drum 6 is installed with support rod 7 through internal and external thread movable, and the top outer surface of support rod 7 is installed with platform 9 through bearing movable, platform The outer surface of the bottom end of 9 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com