Ultra-pure aluminum purification crystallization method

A technology of crystallization and pure aluminum, applied in the field of purification crystallization of ultra-high-purity aluminum, which can solve the problems of low product purity, low purification efficiency, and easy generation of oxides, so as to achieve a stable liquid level and reduce the generation of oxides , to reduce the effect of exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

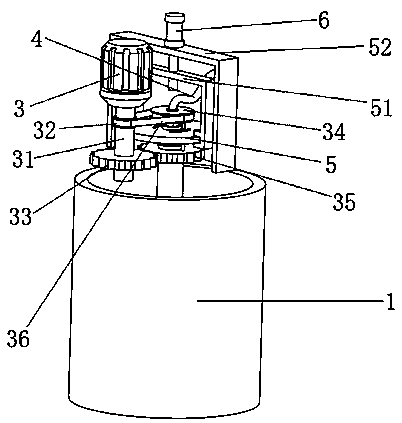

Image

Examples

Embodiment

[0037] Embodiment: Take the purification of 5N aluminum to 5N5 as an example.

[0038] Step 1: Melting a certain amount of 5N aluminum block in a crucible, keeping the temperature at 660-680°C.

[0039] Step 2. Install the purification and crystallization device above the crucible. At this time, the upper rotor 9 and the lower rotor 10 are inserted under the liquid aluminum surface, and the upper rotor 9 is located below the aluminum liquid surface.

[0040] Step 3: 50-100 L / min of normal-temperature air is continuously fed into the crystallization device.

[0041] Step 4: Turn on the rotating motor 3 to continuously rotate the lower rotor 10, control the steering motor 6, so that the upper rotor 9 and the lower rotor 10 rotate in opposite directions, increase the speed to about 80rpm and keep the liquid level from being driven, and rotate During the process, the aluminum liquid with high purity is preferentially solidified due to the cooling action of the crystallization dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com