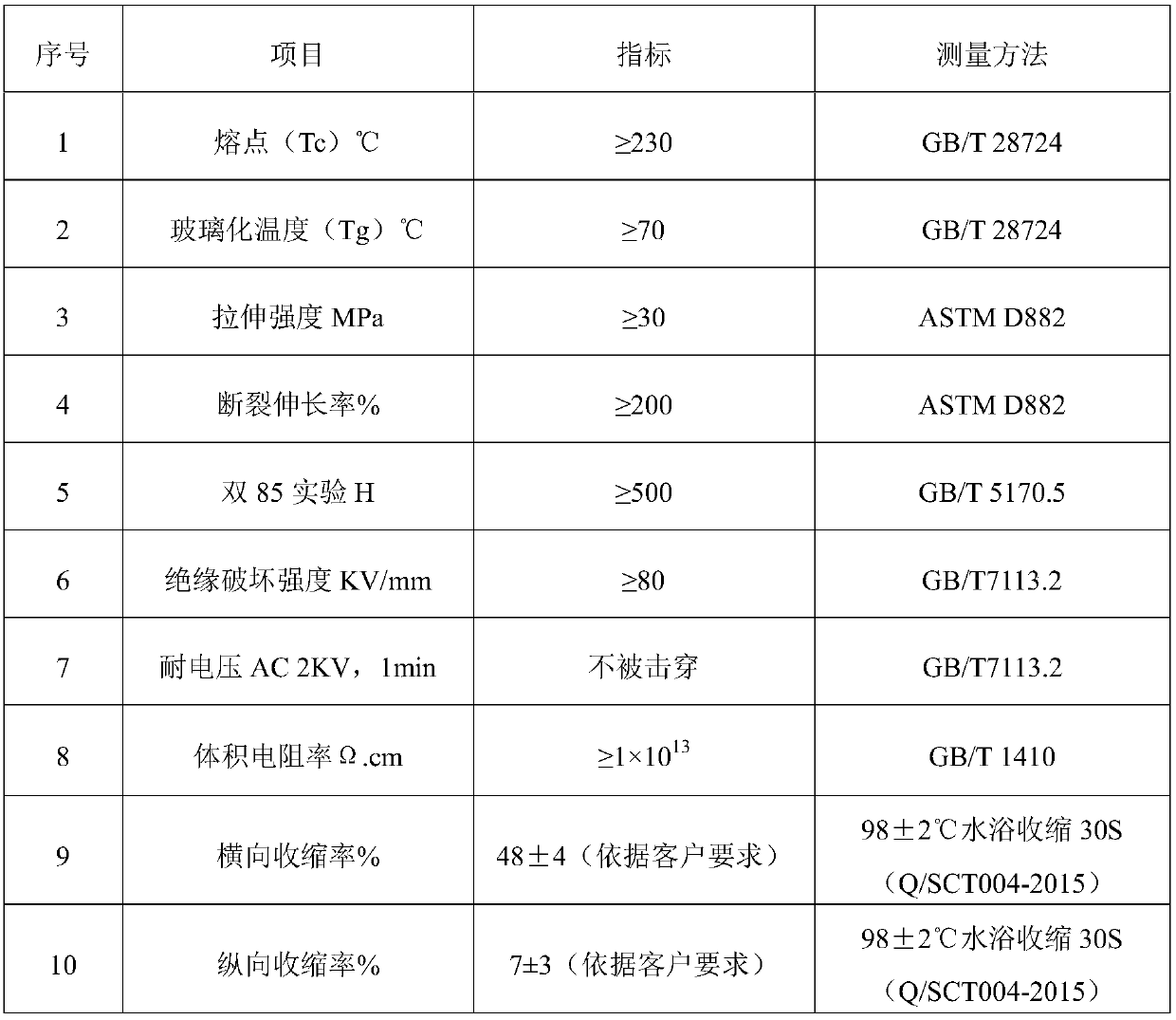

PET heat shrinkable sleeve material with high temperature and high humidity resistance and preparation method of PET heat shrinkable sleeve material

A heat-shrinkable sleeve, high temperature resistance technology, applied in the field of materials, can solve the problems of poor heat dissipation, long working time and other problems, and achieve the effects of excellent mechanical strength and stiffness, excellent high temperature and high humidity resistance, and good shrinkage performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A high-temperature and high-humidity-resistant PET heat-shrinkable tube material, which contains components and their mass percentages: PET45%, PEN 20%, PCTG 25%, TPE 2%, TPEE 6%, and anti-hydrolysis stabilizer monomer Carbodiimide 1%, antioxidant 1%. Antioxidant is a compound of 1010 and 168.

[0026] It adopts the following steps to prepare PET heat shrinkable tubing:

[0027] The first step: Weigh PEN, PCTG, TPE according to the formula (mass ratio), the above materials are dried at 70-80°C for 4-6 hours, mixed uniformly, and then extruded and granulated by a twin-screw extruder to obtain preliminary granulation material;

[0028] The following processing conditions are used for the preliminary granulation of raw materials:

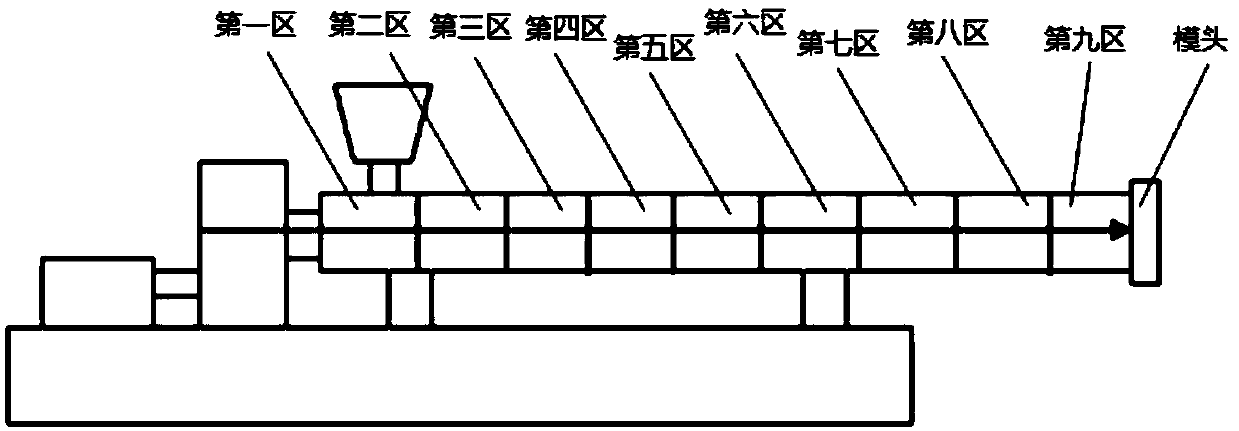

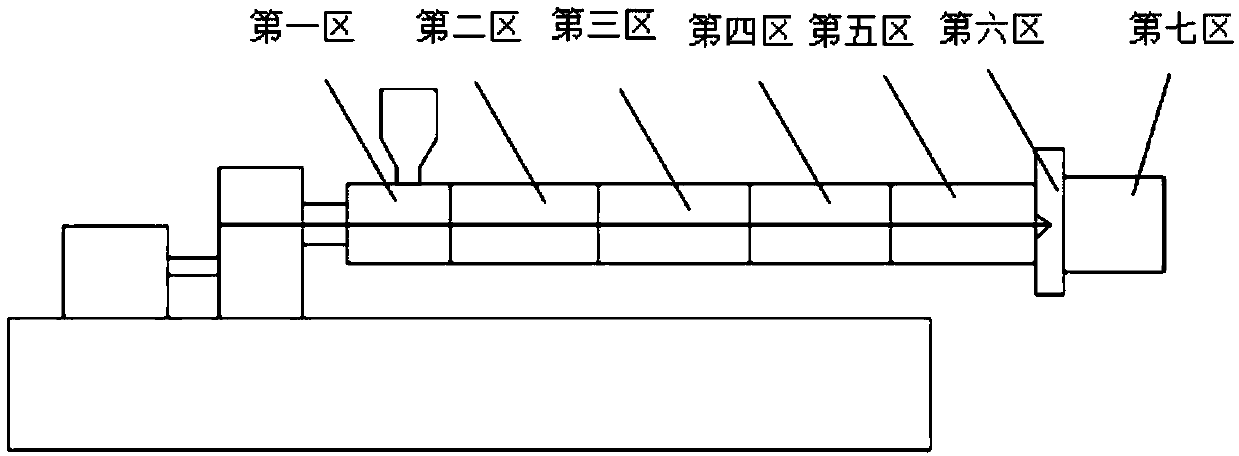

[0029] Such as figure 1 As shown, the temperature of each zone and die of the twin-screw extruder: Zone 1: 120±5°C, Zone 2: 240±5°C, Zone 3: 260±5°C, Zone 4: 265±5°C, Zone 5: 270 ±5℃, six zones: 265±5℃, seven zones: 260±5℃, eight zones: 255±5℃, nine ...

Embodiment 2

[0033] On the basis of Example 1, the components and their mass percentages of the high temperature and humidity resistant PET heat shrinkable tube material of this example are: PET 54%, PEN 20%, PCTG 15%, TPE 2%, TPEE 6% , Anti-hydrolysis stabilizer monomer carbodiimide 2%, antioxidant 1%. Antioxidant is a compound of 1010 and 168.

[0034] The first and second steps of the extrusion process are the same as in Example 1.

Embodiment 3

[0036] On the basis of Example 1, the components and mass percentages of the high temperature and humidity resistant PET heat shrinkable tube material of this example are: PET 64%, PEN 15%, PCTG 15%, TPE 1%, TPEE 6% , Anti-hydrolysis stabilizer monomer carbodiimide 2%, antioxidant 2%. Antioxidant is a combination of 1010 and 168.

[0037] The first and second steps of the extrusion process are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com