Coarse composite foaming material for sneaker soles as well as preparation method and application of coarse composite foaming material

A technology of composite foaming and sports shoes, which is applied in the field of footwear materials, can solve the problems of functional properties that need to be improved, and achieve the effects of reducing physical energy consumption, excellent resilience, excellent resilience and compression resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] Correspondingly, an embodiment of the present invention provides a method for preparing a coarse-cell composite foam material for sports shoes as described above, including the following steps:

[0063] The expandable elastomer composite material is sequentially kneaded and granulated, and then foamed, and the foaming is IP injection foaming and / or small foaming to obtain a coarse-pore composite foaming material for sports shoes.

Embodiment 1

[0073] 1) Weigh the following components by mass parts: polyolefin elastomer Engage8003 17PHR, ethylene vinyl acetate copolymer EVA7470M / EVA40L-03 (the mass ratio of the two is 60 / 40) 45PHR, olefin block copolymer OBC9107 33PHR, polyethylene N -150 5phr.

[0074] 2) Put all the ingredients weighed in step 1) into the Lena machine in order for mixing. The mixing time is 8-10 minutes and the temperature is 110-115°C.

[0075] 3) Weigh the following components by mass parts: high transparent calcium 5PHR, stearic acid 1842 0.5PHR, odorless crosslinking agent 14S-F1 0.75PHR, Poly Foam foaming agent 3.8PHR.

[0076] 4) Add all the ingredients weighed in step 3) to the mixed material in step 2), and use a twin-screw extruder to mix again. The mixing time is 5-7 minutes and the temperature is 115-118 ° C.

[0077] 5) The mixture obtained in step 4) is granulated with a granulator, the granulation time is 9-11 minutes, and the temperature is 110°C-120°C.

[0078] 6) Foaming the mixt...

Embodiment 2

[0080] Corresponding to Example 1, the only difference is that step 6) conducts small foaming for 550-600 seconds at a foaming temperature of 150°C-160°C to obtain a coarse-cell composite foaming material for sports shoe soles.

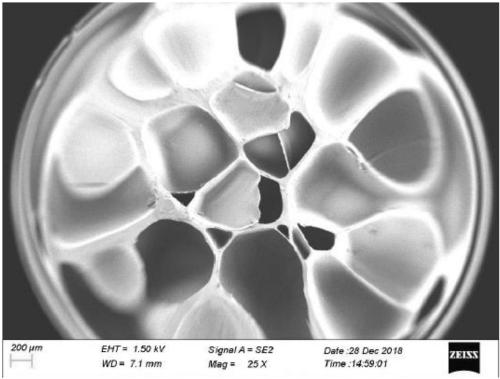

[0081] Carry out electron microscope test to described foam composite material, the result sees figure 1 with figure 2 , figure 1 It is a scanning electron micrograph of the foamed composite material obtained in Example 1 of the present invention at a magnification of 5 mm × 3.1, figure 2 is a ZEISS scanning electron micrograph (200 μm). It can be seen from the figure that the foamed composite material has a coarse-pored and open-celled spherical cell structure with a pore diameter of 0.2-1.0 mm. In addition, the cell structure of the products prepared by the two processes of IP foaming and small foaming is the same.

[0082] Figure 3-5 It is a physical photo of the foamed composite material used as the sole, image 3 It is the magnification ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com