Large-size additive-subtractive-integrated FDM printing head

A printing head, adding and subtracting material technology, applied in the field of additive manufacturing, can solve the problems that affect the surface accuracy and surface finish of printed parts, poor bonding force between parts, a large amount of plastic dust, etc., to achieve a good processing environment and a consistent surface Good performance, low land occupation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

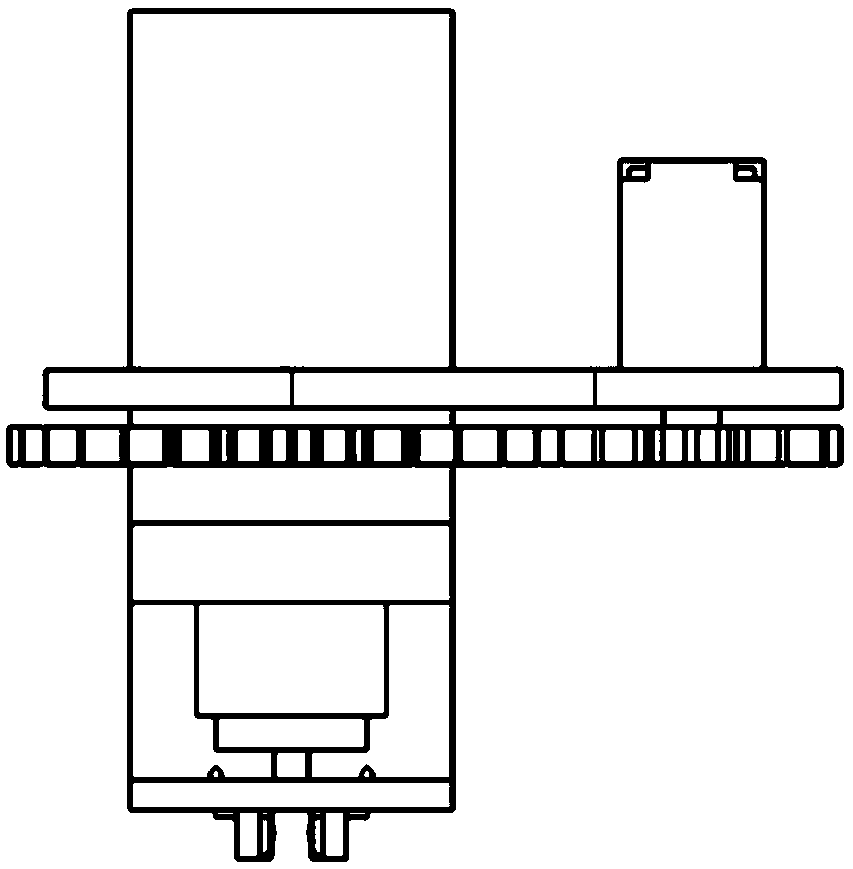

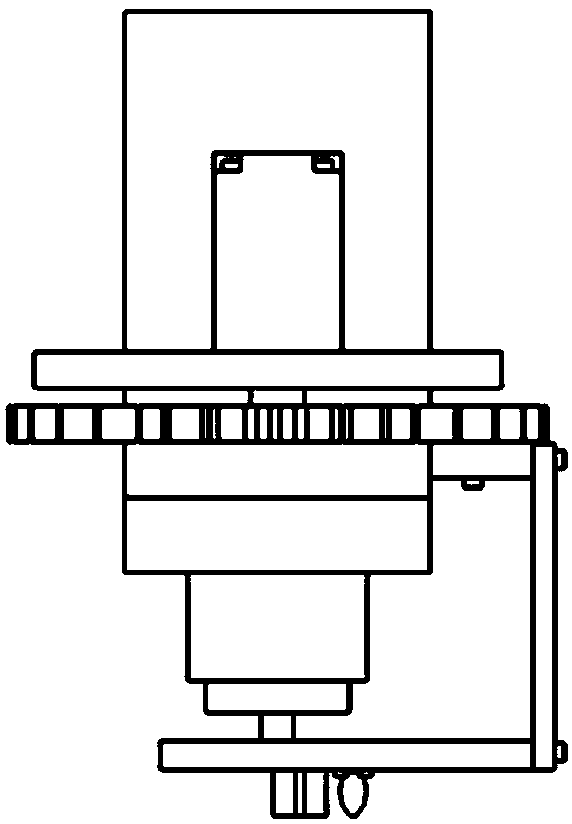

[0034] see figure 1 , figure 2 and image 3 , the present invention discloses an FDM print head integrating large-scale addition and subtraction materials, the print head includes a barrel 1, a motor 2, a motor mounting plate 3, a first fixing plate 4, a second fixing plate 5, a driving gear 6, Moving gear 7, print head 8, wedge-shaped heat channel 9, heat roller 10, rotating shaft 11, ball 12, flange 13, printing end 14, third fixing plate 15, cutting device 16, printing centerline 17, fixing Pile 18, cutter head 19.

[0035] see image 3 and Figure 4 , the upper surface of the motor mounting plate 3 is fixedly provided with a material cylinder 1 and the motor 2, and the material cylinder 1 and the motor 2 are not in contact; the lower surface of the motor mounting plate 3 is fixedly provided with a rotating shaft 11, the axis of the rotating shaft 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com