Honeycombed cement pipe and manufacturing process thereof

A manufacturing process and technology of cement pipes, applied in the direction of manufacturing tools, pipes, rigid pipes, etc., can solve the problems of inability to improve the strength of cement pipes, affect production efficiency, and solidify for a long time, so as to reduce the materials used, Improve production efficiency and reduce the effect of solidification time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

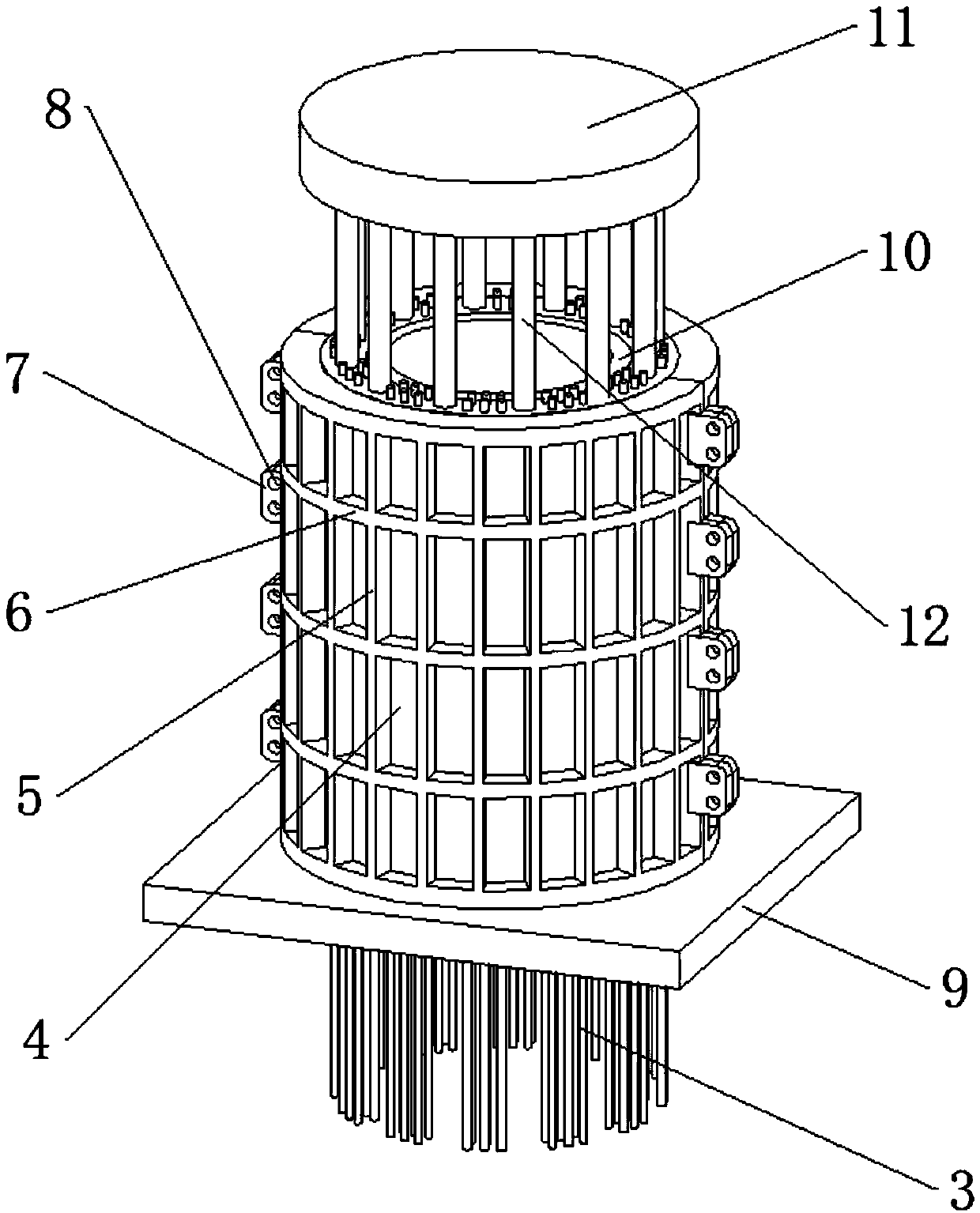

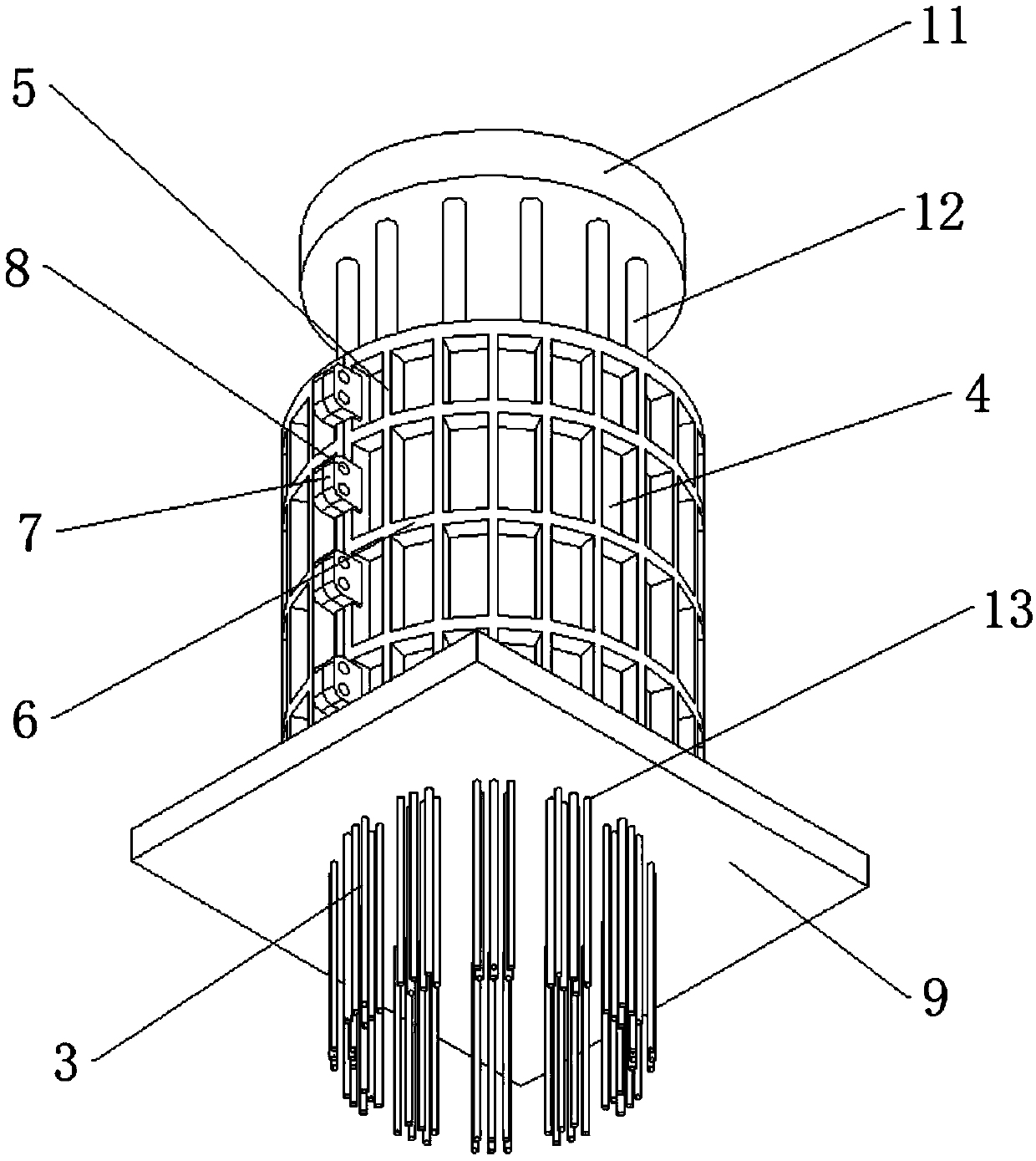

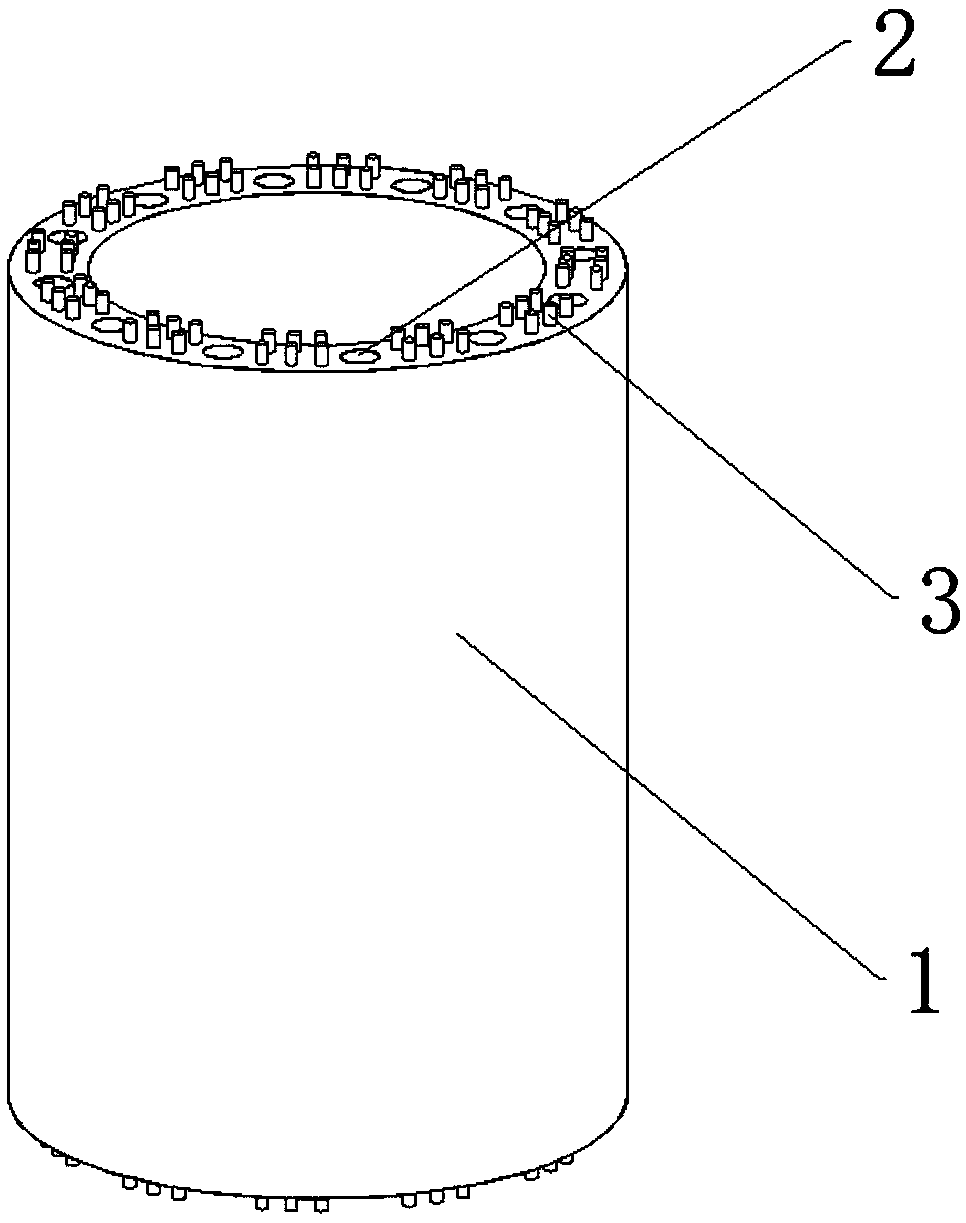

[0043] see Figure 3-4, a porous cement pipe, comprising a porous cement pipe 1, the porous cement pipe 1 is provided with a plurality of uniformly distributed through holes 2, the through holes 2 run through up and down, and the interior of the porous cement pipe 1 is fixedly connected with a plurality of uniformly distributed Steel bar 3, the diameter of steel bar 3 is 4-8 millimeter.

[0044] The material of the porous cement pipe 1 is concrete, and the strength grade of the concrete is C30. The raw materials of the concrete include water, cement, sand, stones and concrete additives. The cement surplus coefficient of the concrete is 1.00, and the maximum particle size of the coarse aggregate is 20 mm. The density is 35-50 mm, the sand rate is 28-30%, the water-cement ratio is 0.36-0.39, the concrete reference ratio is: cement: sand: gravel: water = 1:1.54:2.88:0.43, the concrete capacity is 2400kg / m3; cement dosage: 410kg / m3; sand: 632kg / m3; gravel: 1181kg / m3; water: 175k...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com