Thread self-locking lateral compressing mechanism

A pressing mechanism and self-locking technology, applied in the directions of metal processing machinery parts, clamping, support, etc., can solve the problems of increasing the manufacturing cost of tooling, the opening of the processing surface, affecting the efficiency of CNC machining, and the non-opening of the processing surface. The danger of the knife, the reliable clamping, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

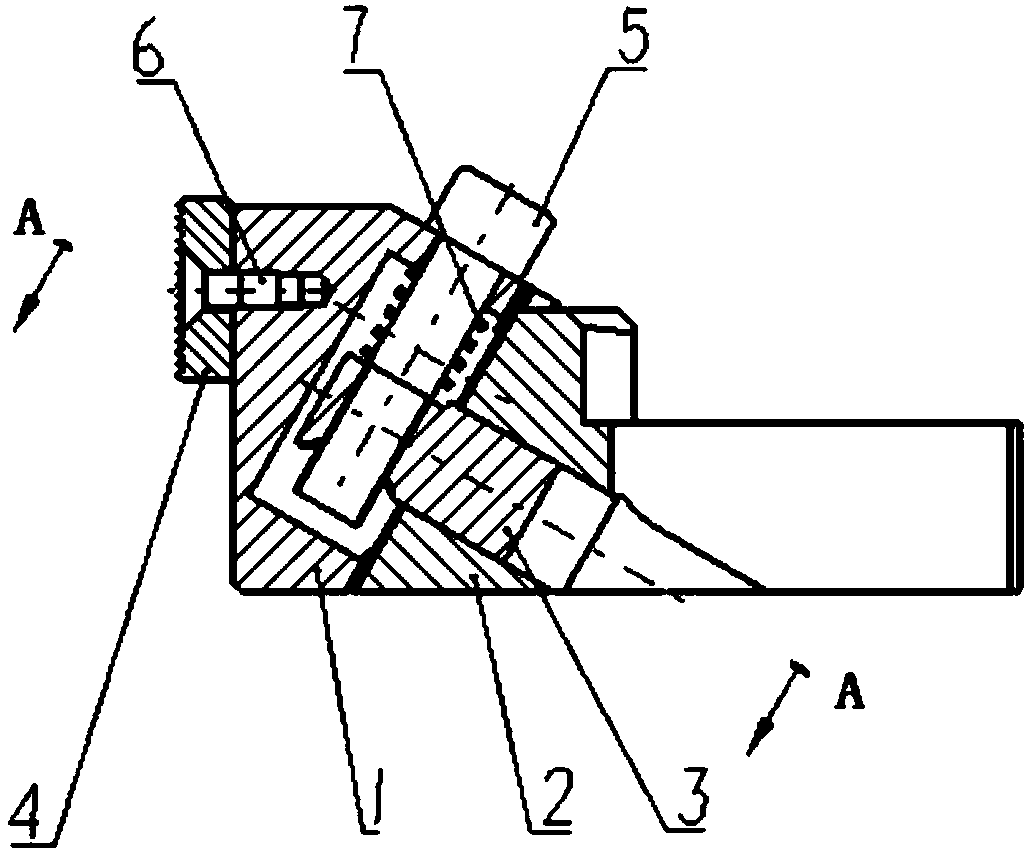

[0019] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

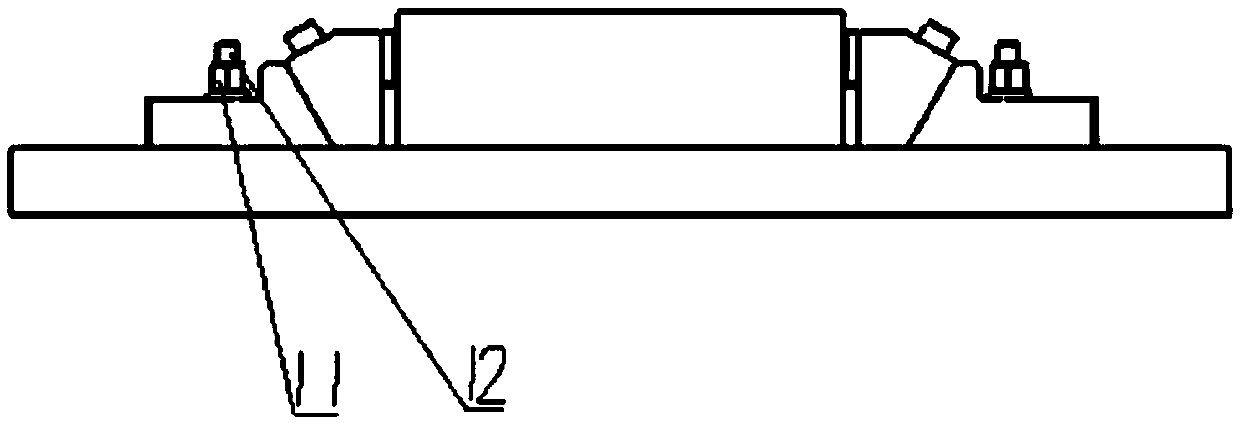

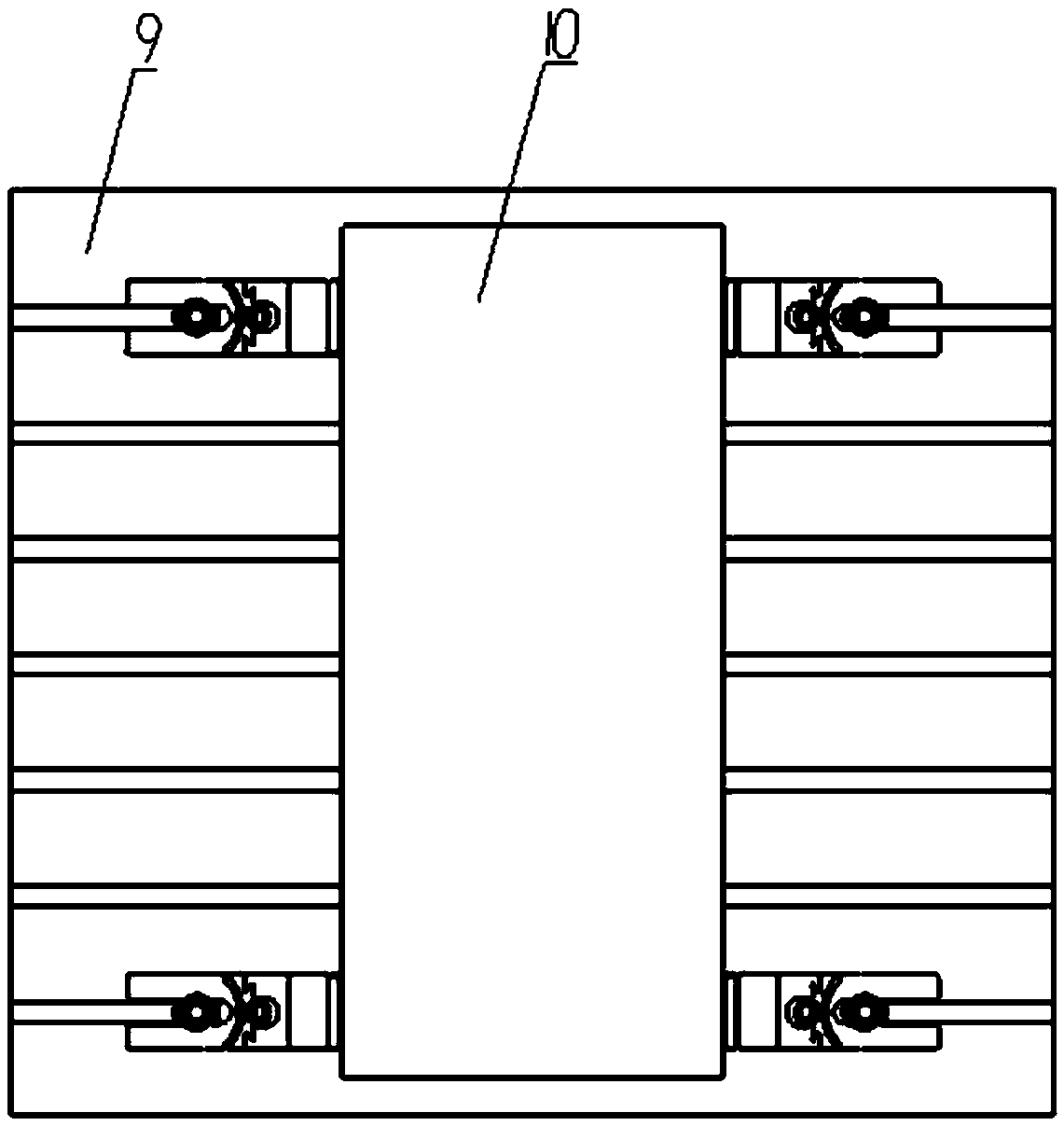

[0020] Such as figure 1 As shown, a threaded self-locking lateral pressing mechanism includes a main body part, a T-slot table 9, a shoulder nut 11 and a T-bolt 12;

[0021] The main parts are symmetrically fixed on the T-shaped groove workbench 9, and the parts 10 are placed between the symmetrical main parts to realize the compression of the parts 10; the main parts include a movable pressure head 1, a fixed body 2, a self-locking nut 3, Toothed pressure plate 4, compression screw 5, countersunk screw 6, helical compression spring 7 and cylindrical pin 8;

[0022] The fixed body 2 is in the shape of a V-shaped block, with a U-shaped groove at the horizontal end, and is connected with the T-shaped groove worktable 9 through shoulder nuts 11 and T-shaped bolts 12; the inclined end of the fixed body 2 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com