A thin-walled metal tube stretch bending method

A metal tube and thin-walled technology, which is applied in the field of metal processing and forming, can solve problems such as the need for compression length, thin-walled metals are prone to instability, and tube wall fractures, and achieve the effect of reducing risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Embodiments of the present invention are described in detail below, and it should be understood that the embodiments are exemplary and are only used for explaining the present invention, and should not be construed as limiting the present invention.

[0013] A thin-walled metal pipe stretch bending method provided by the present invention will be further described and explained below in conjunction with the accompanying drawings.

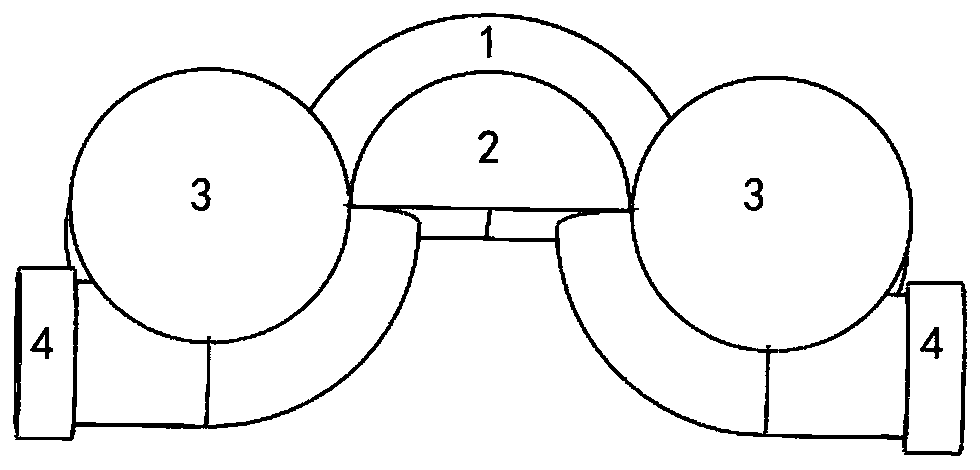

[0014] Such as figure 1 As shown, a thin-walled metal pipe stretch bending method proposed by the present invention is to use a stretch bending device to stretch and bend the thin-walled metal pipe. Add two profiling rollers 3 for auxiliary deformation, the diameter of the profiling rollers 3 is the same as that of the mold 2, and the shape of the profiling rollers 3 matches the shape of the blank pipe 1.

[0015] The stretch-bending device further includes a collet 4, which is arranged at a position corresponding to the profiling roller 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com