Preparation and application of compound catalyst for preparing diphenyl carbonate

A technology of diphenyl carbonate and dimethyl carbonate, applied in the field of composite heterogeneous catalysts, can solve problems such as low activity and selectivity of heterogeneous catalysts, and achieve the effect of ensuring activity and selectivity and good technical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

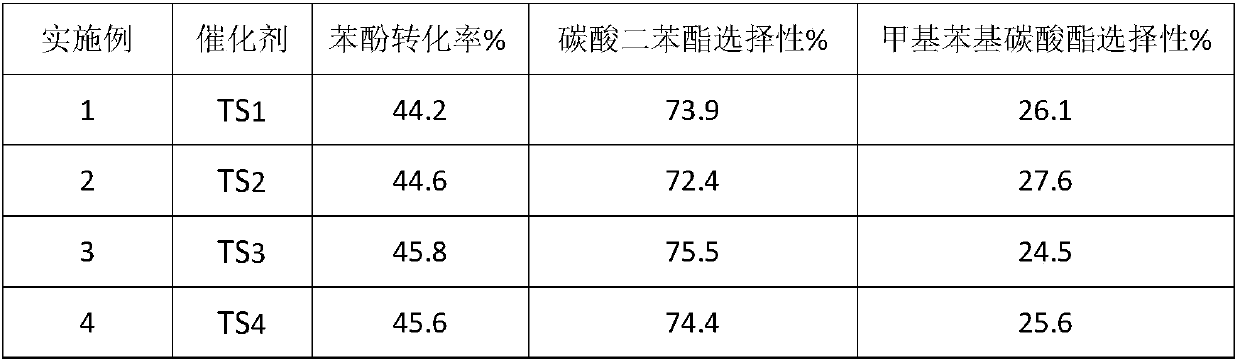

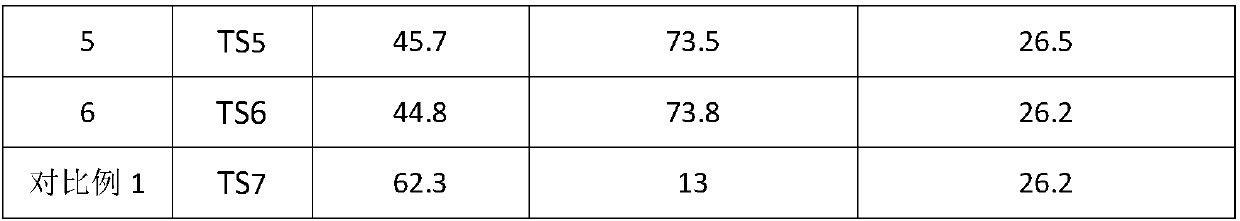

Examples

Embodiment 1

[0029] Dissolve 8g of tetrapropylammonium hydroxide and 0.1g of sodium hydroxide in 60ml of deionized water, add 3g of carbon nanospheres (20nm in diameter), heat at 80°C for 3h, add 20.8g of tetraethyl silicate and stir, transfer to In the autoclave, let it stand at 160°C for 3 days, wash the solid and dry it, then roast it at 400°C for 24h.

[0030] To obtain 10g of solid, dissolve 6g of titanium tetrachloride in 10g of toluene, mix and stir for 30min, extract the solvent toluene to obtain a white solid, impregnate with 10g of phenol, add methanol, filter and wash to obtain catalyst sample TS1. The catalyst loading is 20%, the pore size is 20nm, and the molecular sieve diameter is about 300nm.

Embodiment 2

[0032] Dissolve 8g of tetrapropylammonium hydroxide and 0.1g of sodium hydroxide in 60ml of deionized water, add 4g of carbon nanospheres (30nm in diameter), heat at 80°C for 3h, add 20.8g of tetraethyl silicate and stir, transfer to In the autoclave, let it stand at 170°C for 4 days, wash the solid and dry it, then roast it at 500°C for 24h.

[0033] To obtain 10g of solid, dissolve 6g of tetrabutyl titanate in 10g of toluene, mix and stir for 30min, extract the solvent toluene to obtain a white solid, impregnate with 10g of phenol, add methanol, filter and wash to obtain catalyst sample TS2 , The catalyst loading is 20%, the pore size is 30nm, and the molecular sieve diameter is about 400nm.

Embodiment 3

[0035] Dissolve 8g of tetrapropylammonium hydroxide and 0.1g of sodium hydroxide in 60ml of deionized water, add 5g of carbon nanospheres (50nm in diameter), heat at 80°C for 3h, add 20.8g of tetraethyl silicate, stir, and transfer to In the autoclave, let it stand at 170°C for 6 days, wash the solid and dry it, then roast it at 400°C for 48h.

[0036] Obtain 10g of solid, dissolve 6g of titanium sulfate in 10g of water, mix and stir for 30min, draw out the solvent water to obtain a white solid, impregnate with 10g of phenol, add methanol, filter, and wash to obtain a catalyst sample TS3 with catalyst loading The amount is 20%, the pore size is 50nm, and the molecular sieve diameter is about 500nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com