A preparation method of an underwater superoleophobic oil-water separation membrane based on tannic acid modification

An oil-water separation mesh membrane, underwater superoleophobic technology, applied in separation methods, liquid separation, semi-permeable membrane separation and other directions, can solve the problems of cumbersome preparation process, high cost, unsuitable for industrial production and application, etc. Simple, easy to operate, low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

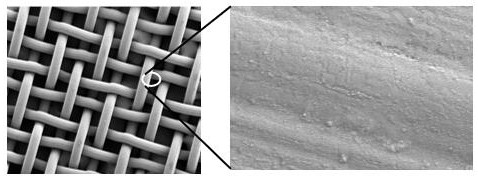

[0029] (1) Clean the 400-mesh stainless steel mesh and dry it for later use.

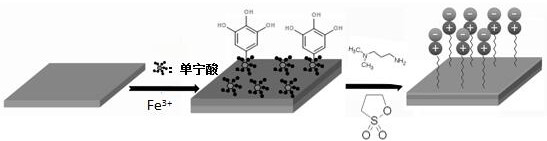

[0030] (2) Dissolving tannic acid in water, adjusting the pH to 8.3, to obtain a tannic acid solution with a mass percentage of tannic acid of 3%; dissolving ferric chloride in water to obtain the mass percentage of iron ions It is a 1% iron ion solution; N,N-dimethyl-1,3-diaminopropane is dissolved in water, and the mass percentage of N-dimethyl-1,3-diaminopropane is 5% The tertiary amine modified solution of 1,3-propane sultone was dissolved in methanol to obtain a zwitterion modified solution with a mass percentage of 1,3-propane sultone of 2%.

[0031] (3) Soak the dried stainless steel mesh in tannic acid solution, soak it for 10 seconds, take it out to dry; then soak it in iron ion solution, soak it for 5 seconds, take it out and dry it; repeat this process 6 times; After taking out, it is dried in a drying oven at 80°C for 6 hours to obtain a tannic acid modified fabric web;

[0032] (4) Im...

Embodiment 2

[0036] (1) Clean the 300-mesh stainless steel mesh and dry it for later use.

[0037] (2) Dissolving tannic acid in water, adjusting the pH to 8, to obtain a tannic acid solution with a mass percentage of tannic acid of 4%; dissolving ferric chloride in water to obtain the mass percentage of iron ions It is a 0.5% iron ion solution; N,N-dimethyl-1,3-diaminopropane is dissolved in ethanol, and the mass percentage of N-dimethyl-1,3-diaminopropane obtained is 2 % tertiary amine modification solution; dissolve 1,3-propane sultone in ethanol to obtain a zwitterion modified solution with a mass percentage of 1,3-propane sultone of 2%.

[0038] (3) Soak the dried stainless steel mesh in tannic acid solution, soak it for 1 hour, then take it out to dry; then soak it in iron ion solution, soak it for 20 seconds, then take it out to dry; this process is repeated 4 times; After taking out, it is dried in a drying oven at 60°C for 6 hours to obtain a tannic acid-modified fabric web;

[...

Embodiment 3

[0042] (1) Clean the 100-mesh copper mesh and dry it for later use.

[0043] (2) Dissolving tannic acid in ethanol, adjusting the pH to 9.0 to obtain a tannic acid solution with a mass percentage of tannic acid of 0.1%; dissolving ferric chloride in ethanol to obtain a mass percentage of iron ions Iron ion solution with a content of 0.01%; Dissolve N,N-dimethyl-1,3-diaminopropane in ethanol to obtain the mass percentage of N-dimethyl-1,3-diaminopropane 0.01% tertiary amine modification solution; dissolving γ-butyrolactone in ethanol to obtain a zwitterion modification solution with a mass percentage of γ-butyrolactone of 0.01%.

[0044] (3) Soak the dried copper mesh in the tannic acid solution, soak for 30 seconds, take it out and dry it; then soak it in the iron ion solution, soak it for 30 seconds, take it out and dry it; repeat this process 15 times; After taking it out, dry it in a drying oven at 50°C for 0.5 hour to obtain a tannic acid modified fabric net;

[0045] (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com