Processing method of black tea with strong flower fragrance

A processing method and a flower-flavor technology, which are applied to the processing field of floral-flavor high-fragrance dark tea, can solve the problems of non-revealing black tea's floral fragrance and low efficiency, and achieve the effects of strong endoplasmic taste, ensuring safety, and balanced water distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

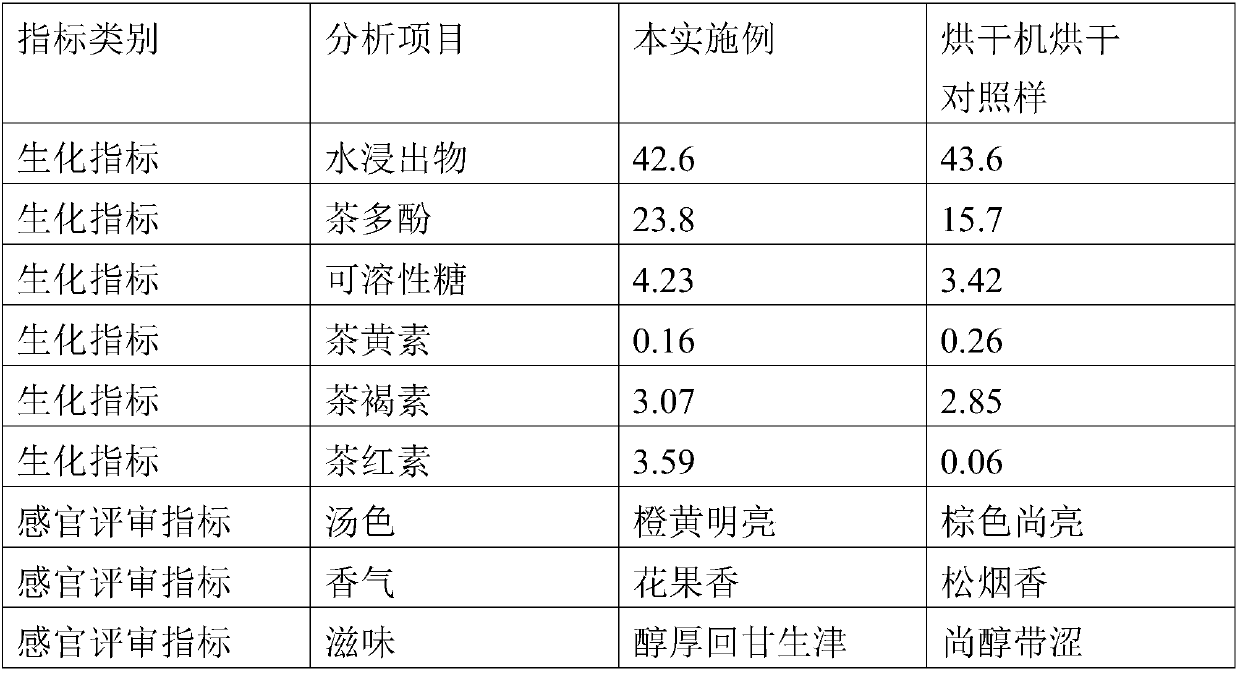

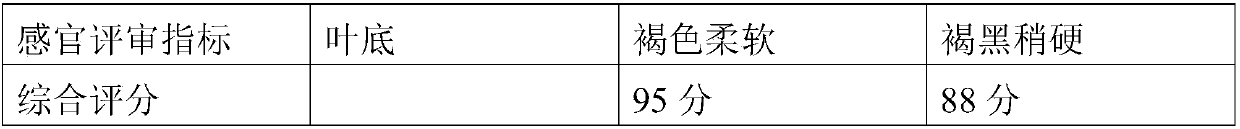

Examples

Embodiment 1

[0023] Embodiment 1 The embodiment proposes a kind of processing method of flower-flavor type high fragrance dark tea, comprises the following steps:

[0024] A. Picking: pick the fresh leaves of Blue Mountain big-leaf bitter tea with one bud and four or five leaves;

[0025] B. Spread green: spread the picked fresh leaves on bamboo mats with a thickness of 4.5cm for 1.5 hours;

[0026] C. Sunshine: Before ten o'clock in the morning and after four o'clock in the afternoon, put the fresh leaves and bamboo mats in the sun for 30 minutes, and turn them once in the middle;

[0027] D. Cooling: Take the fresh leaves exposed to the sun together with bamboo mats to the greening workshop for cooling for 1 hour;

[0028] E. Sprinkling and grouting: pile the cooled tea leaves into piles, prepare water according to the weight ratio of tea leaves: water = 1:0.2, and sprinkle water into the piles of tea leaves, turn the piles and stir to mix the water and tea evenly;

[0029] F. High-tem...

Embodiment 2

[0049] The present embodiment proposes a kind of processing method of flower-flavor type high fragrance black tea, comprises the following steps:

[0050] A. Picking: pick the fresh leaves of Blue Mountain big-leaf bitter tea with one bud and four or five leaves;

[0051] B. Green spreading: Spread the picked fresh leaves on bamboo mats with a thickness of 4cm for 2 hours;

[0052] C. Sunshine: Before ten o'clock in the morning and after four o'clock in the afternoon, put the fresh leaves and bamboo mats in the sun for 30 minutes, and turn them once in the middle;

[0053] D. Cooling: Take the fresh leaves exposed to the sun together with bamboo mats to the greening workshop for cooling for 1 hour;

[0054] E. Sprinkling and grouting: pile the cooled tea leaves into piles, prepare water according to the weight ratio of tea leaves: water = 1:0.2, and sprinkle water into the piles of tea leaves, turn the piles and stir to mix the water and tea evenly;

[0055] F. High-temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com