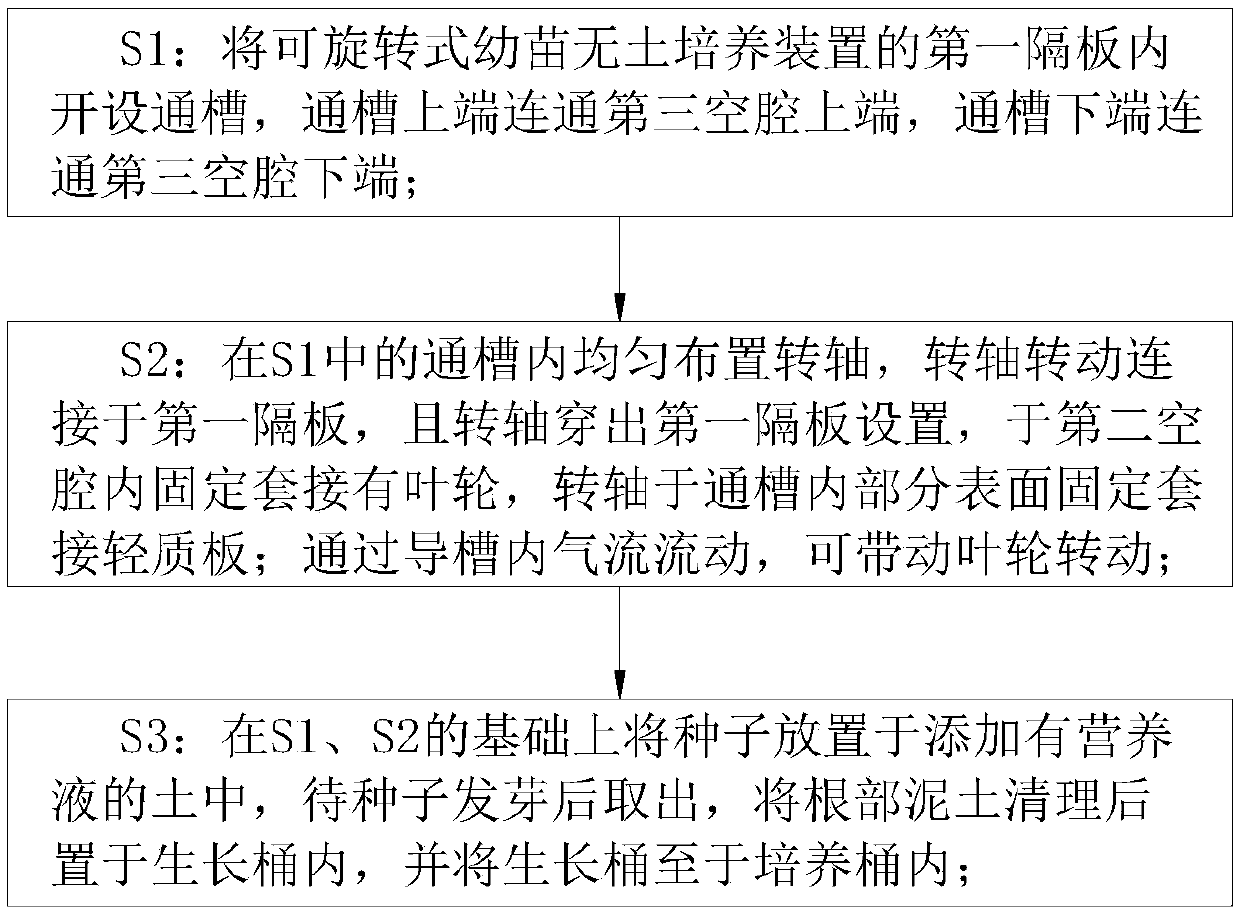

Soilless culture process for young seedling

A technology for soilless culture and seedlings, applied in soilless culture, cultivation, botany equipment and methods, etc., can solve the problems of complicated garbage sedimentation and cleaning, easy to damage seedling rhizomes, complicated water changing steps, etc., to achieve convenient disassembly, prevent The effect of garbage precipitation and growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

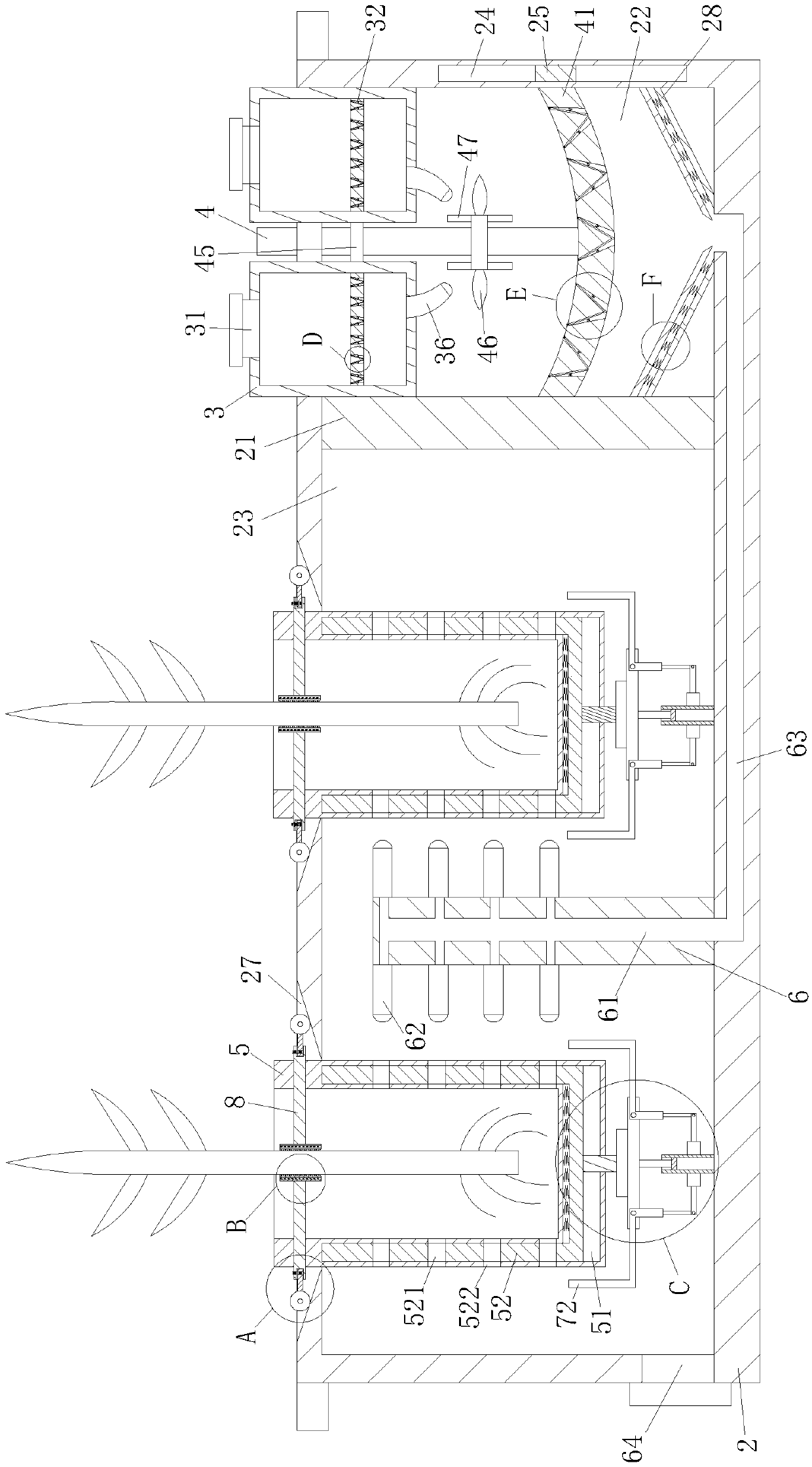

[0040] As an embodiment of the present invention, the engaging unit 85 includes a fifth fixing rod 851, a graphite plate 852 and a fifth spring 853; the end of the sliding rod 81 away from the clamping plate 82 is provided with a groove 86; One end of the fifth fixed rod 851 penetrates into the groove 86, and the other end is fixedly connected with the roller 83; the graphite plate 852 is located between the fifth fixed rod 851 and the bottom inner wall of the groove 86; There is a fifth through hole 854 communicating with the groove 86; the surface of the fifth fixed rod 851 is provided with a sixth through hole 855, and the fifth through hole 854 can communicate with the sixth through hole 855; the fifth spring 853 is located at the first In the five through holes 854 and the sixth through holes 855, the fifth fixed rod 851 can be fixedly connected with the slide bar 81; during use, the disassembly and installation of the roller 83 can be facilitated by the fifth spring 853, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com