Oil filtering device for electrified oil filter of ultra-high voltage transformer

A transformer and ultra-high voltage technology, which is applied in the field of oil filtration equipment for ultra-high voltage transformers, which are charged and finely filtered for nine indicators of transformer oil, can solve the problems of low efficiency, high cost, and long working time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

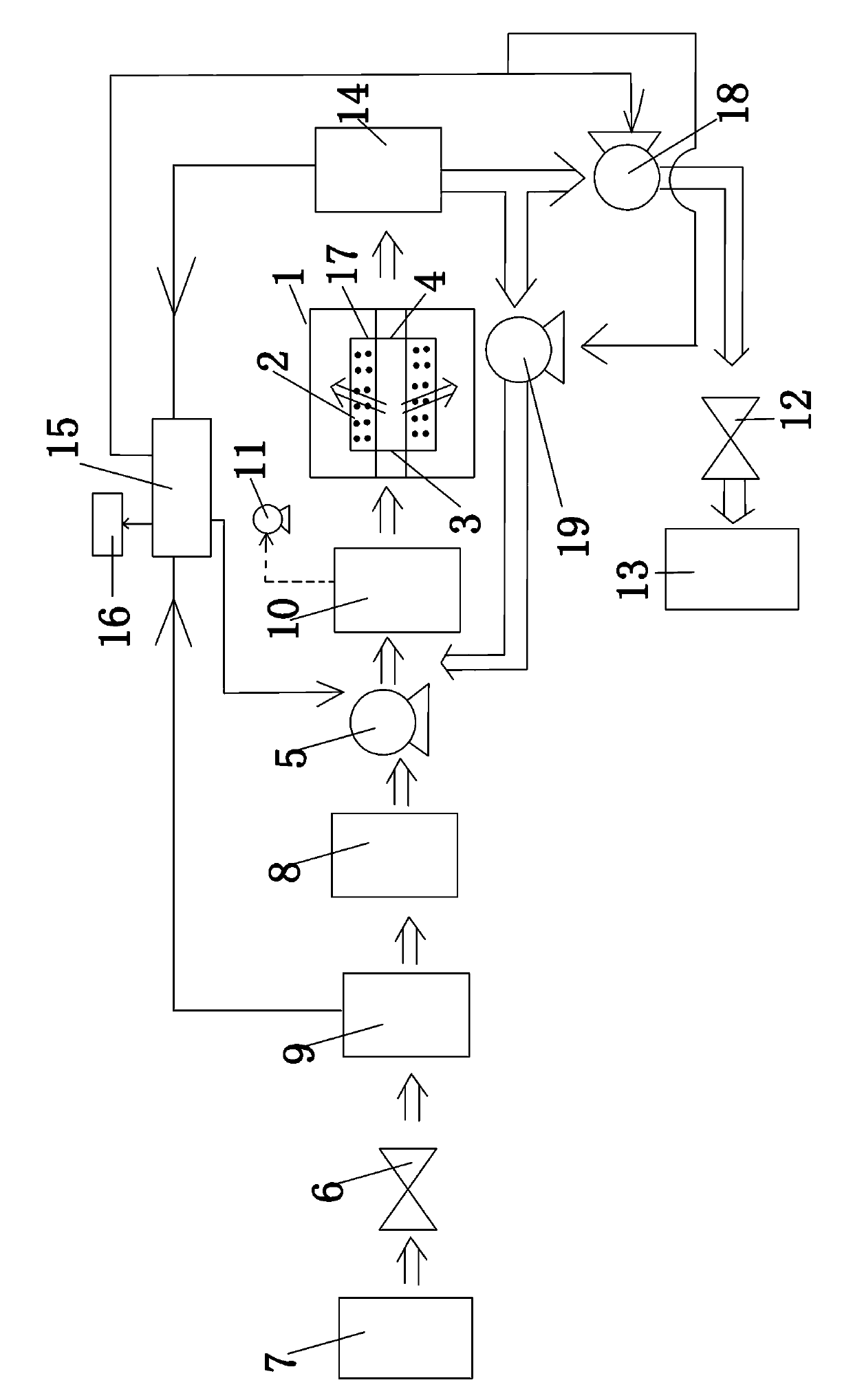

[0034] An oil filtering device for live oil filtering of ultra-high voltage transformers, comprising a filter tank 1.

[0035] There is a filter element 2 (composite solid filter element) inside the filter tank 1. The filter tank 1 includes the outer shell of the filter element, and the filter element 2 is arranged inside the outer shell of the filter element. The filter element 2 is a cylinder. Body inlet 3, and the other end is core body outlet 4.

[0036] The outer casing of the filter element has an inlet of the outer casing of the filter element, the pipeline is connected to the inlet 3 of the core body, and the outlet 4 of the core body is sealed by a sealing plate 17 . The sealing plate 17 is fixedly supported in the outer casing of the filter element at the same time.

[0037] There is a gap between the filter element 2 and the outer housing of the filter element. The outer casing of the filter element also has an outlet of the outer casing of the filter element, whi...

Embodiment 2

[0063] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0064] The filter element 2 is mainly made of 3.5 parts of activated clay, 6 parts of silica gel and 0.5 part of adsorbent.

[0065] The curing agent is a resin, and the quality of the resin is 9% of the sum of the mass of activated clay, silica gel and adsorbent.

[0066] The ingredients of the filter element 2 are used when the oil medium loss value is 1-4% at 90°C.

Embodiment 3

[0068] Embodiment 2 is basically the same as Embodiment 1, and its difference is:

[0069] The filter element 2 is mainly made of 9.5 parts of silica gel and 0.5 parts of adsorbent.

[0070] The curing agent is resin, and the mass of resin is 10% of the sum of silica gel and adsorbent mass.

[0071] The ingredients of the filter element 2 are used when the oil medium loss value is 0.5-1% at 90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com