An intelligent handling robot for concrete pc components

A technology of intelligent handling and robotics, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of high labor energy consumption, low safety of mold tables, inaccurate positioning, etc., and achieve good synchronization and accurate positioning , good level effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

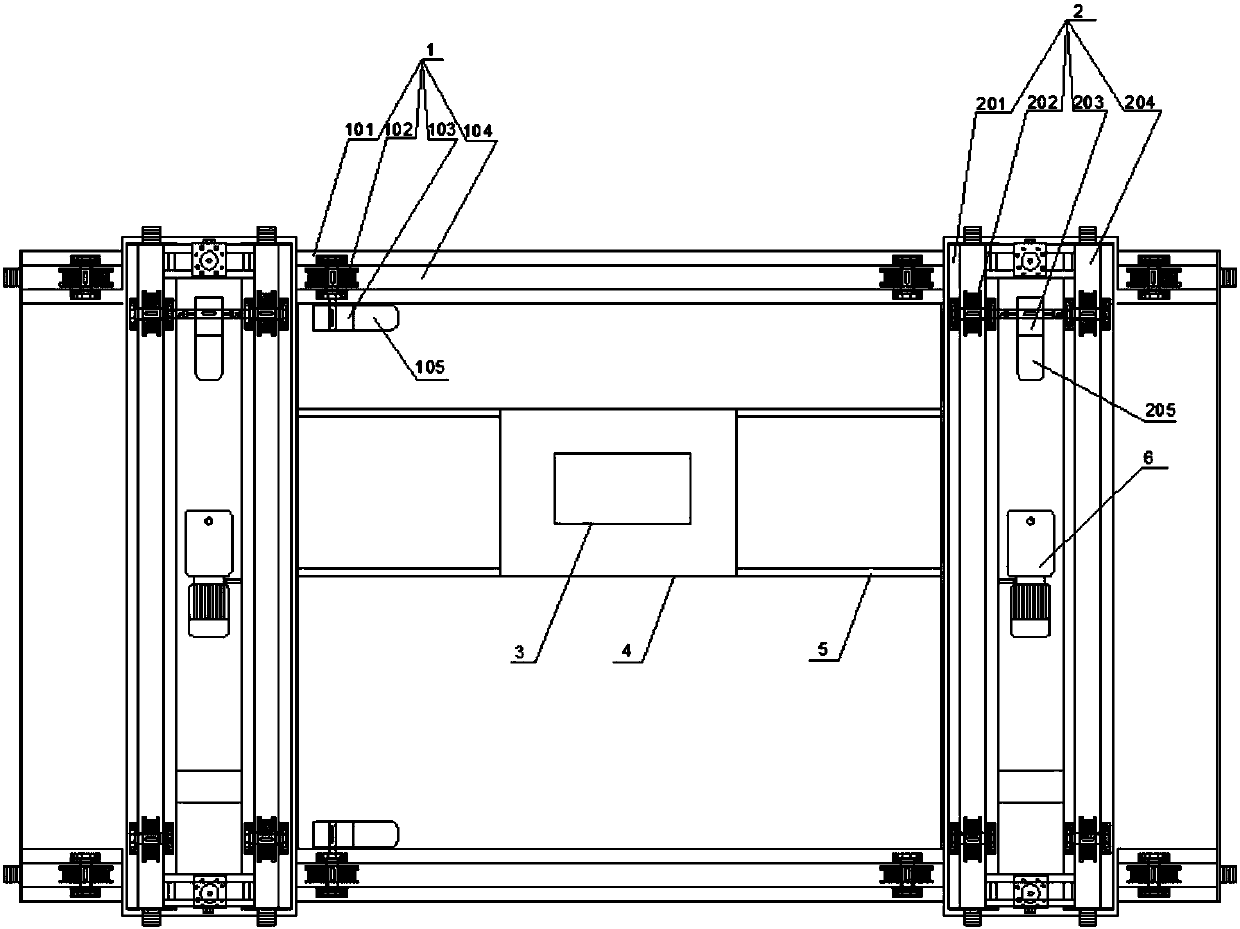

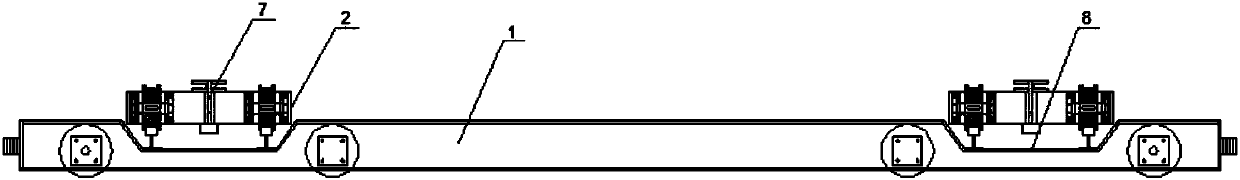

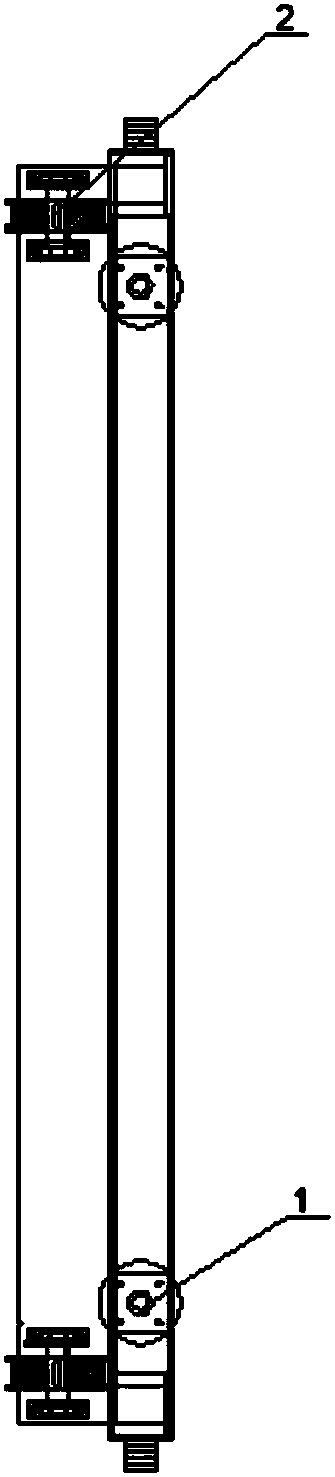

[0018] An intelligent handling robot for concrete PC components, such as Figure 1-4 As shown, it includes a bottom trolley 1 and two upper trolleys 2, the bottom trolley 1 is provided with a groove 8, and the groove 8 is provided with an upper trolley 2. Through the groove 8, the overall height of the intelligent handling robot is reduced, which prevents the intelligent handling robot from being unable to enter under the mold table due to its high height.

[0019] The bottom trolley 1 comprises a bottom frame 101, a bottom roller 102, a bottom trolley driving mechanism 103, a bottom guide rail 104, and a bottom positioning perception system 105. The perception system 105 controls the rotation of the bottom roller 102 through the bottom trolley driving mechanism 103; the bottom driving mechanism 103 drives the bottom roller 102 to slide on the bottom guide rail 104, forming the lateral movement of the intelligent handling robot, thereby controlling the movement of the mold tab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com