Coal-fired flue gas pretreatment system and method

A coal-fired flue gas and pretreatment technology, applied in the preparation of test samples, etc., can solve the problems affecting the accuracy and stability of the experiment, fluctuate the flue gas composition, and the experimental process is cumbersome, etc., to achieve high efficiency of gas pretreatment , Reduce the maintenance workload and ensure the best adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The application will be further described below in conjunction with the accompanying drawings and embodiments.

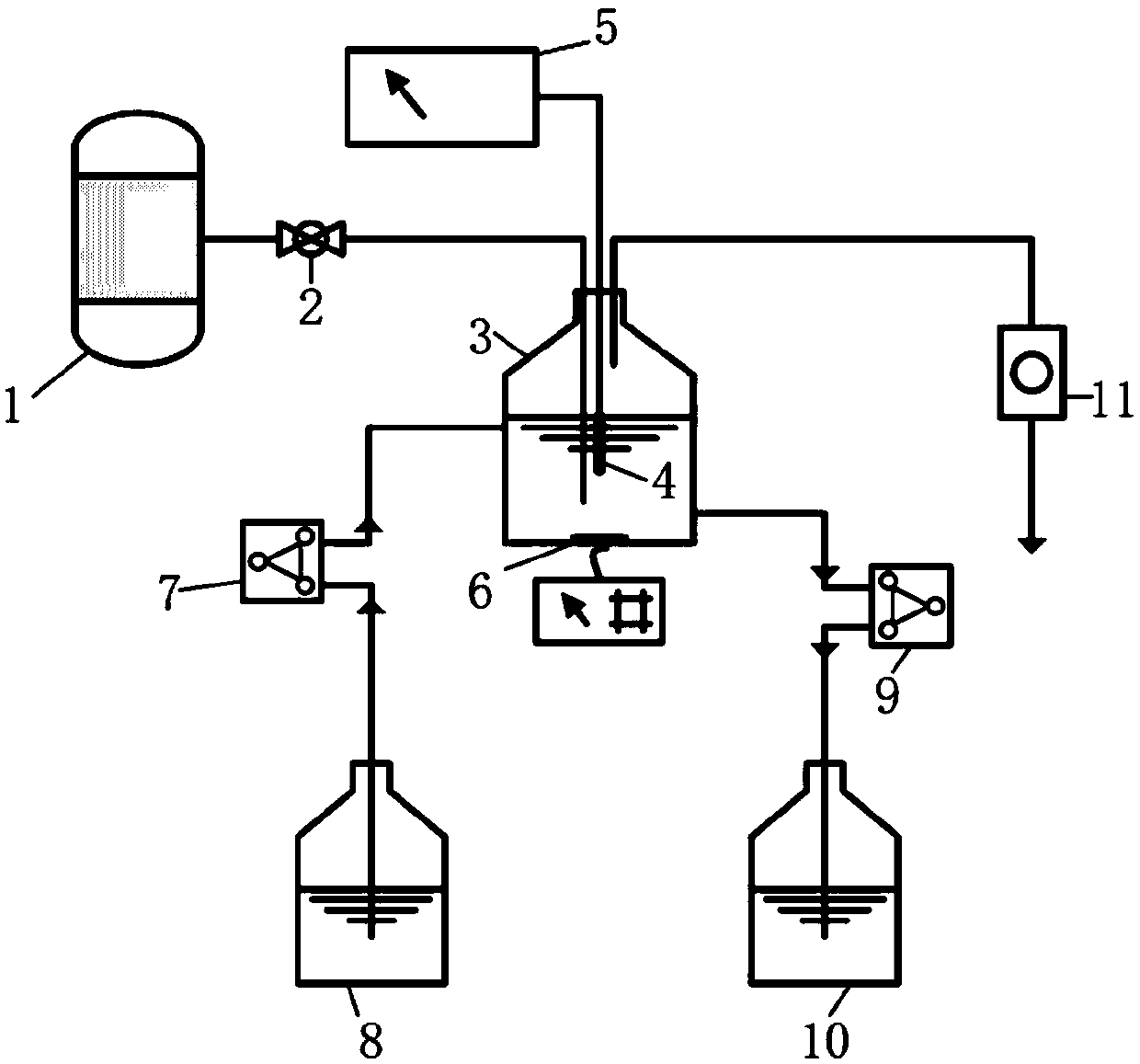

[0034] The application relates to a method and device for pretreatment of coal-fired flue gas. The device can improve the efficiency of gas pretreatment and reduce costs. As shown in the figure: it mainly includes the flow control device (2) reaction container (3) pH detector (5) first peristaltic pump (7) fresh test solution storage bottle (8) connected to the flue (1) A second peristaltic pump (9), a waste liquid storage bottle (10) and an exhaust gas treatment device (11).

[0035] Wherein, the pH detector (5) controls the operation of the first peristaltic pump (7) and the second peristaltic pump (9) through the control system, and when the indication value of the pH detector (5) is less than a certain reference value, the control system controls The first peristaltic pump (7) and the second peristaltic pump (9) run, when the indication value of the pH d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com