Luban stone coating system and construction method thereof

A construction method and painting technology, applied in the direction of coating, construction, building structure, etc., can solve the problems of inability to express, roughness, etc., and achieve the effect of strong decorative effect, strong texture and good waterproofness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

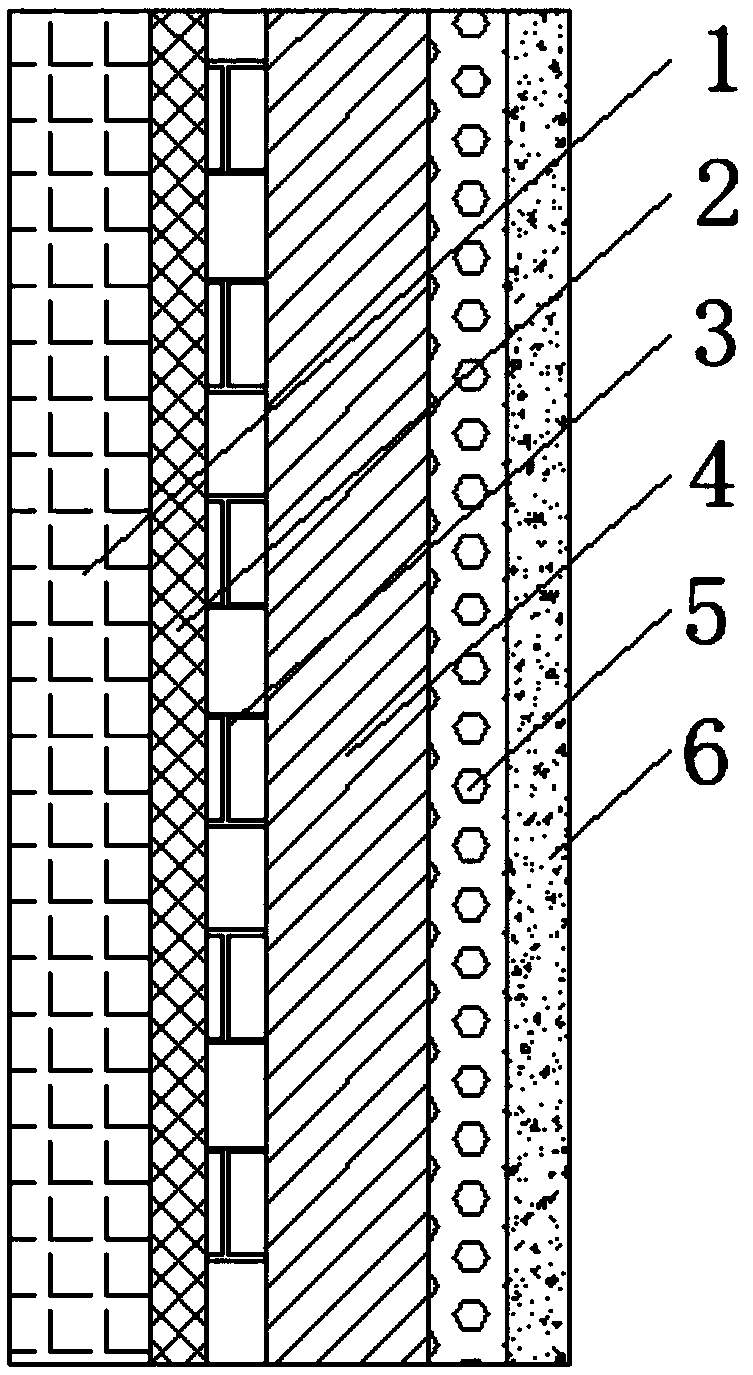

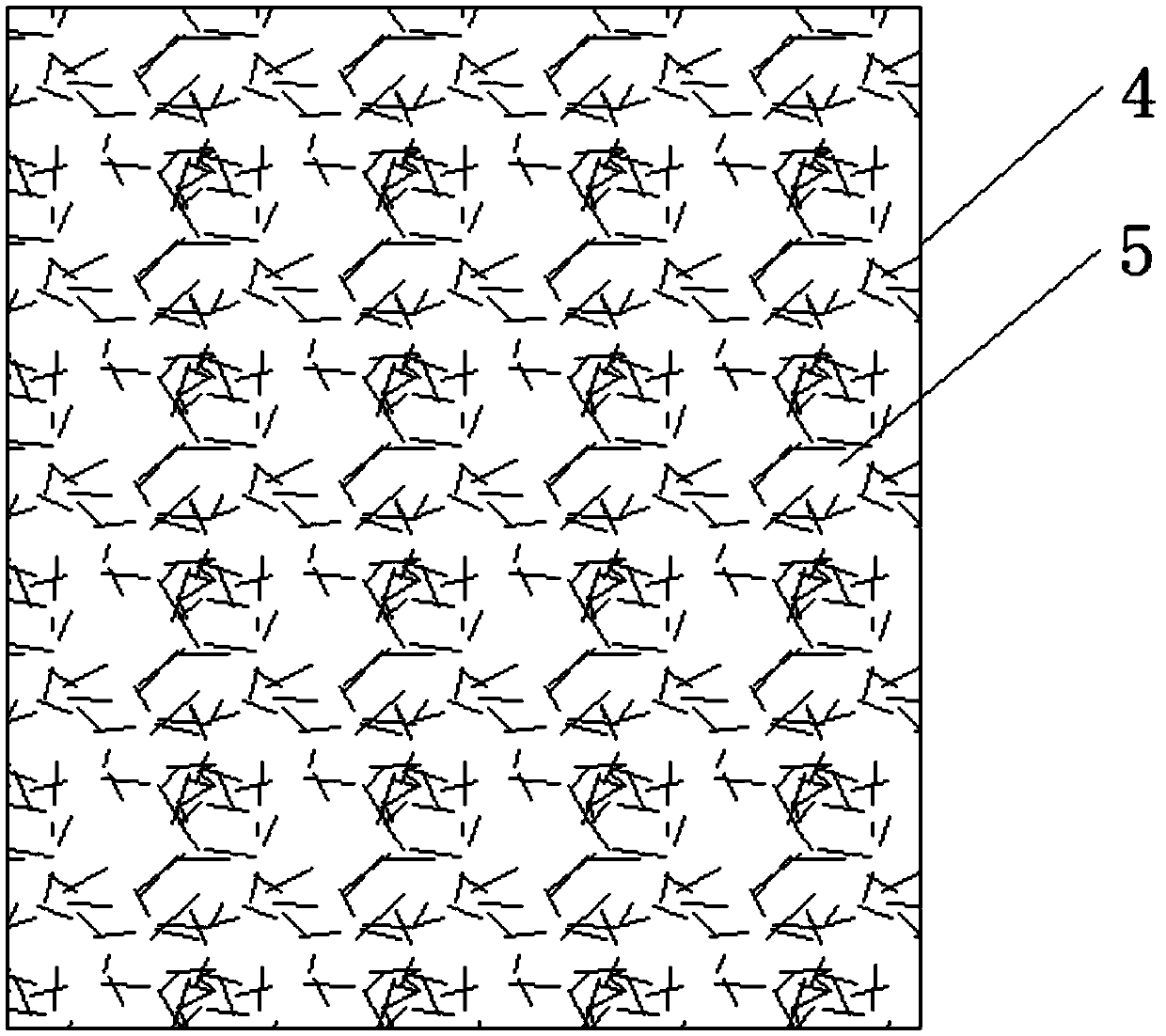

[0028] see Figure 1-2 , the present invention provides a kind of technical scheme: a kind of Luban stone coating system, comprises base layer 1, and the upper surface of base layer 1 is coated with putty layer 2, and the outer layer of putty layer 2 is coated with primer layer 3, and primer layer 3 The outer layer is sprayed with Luban stone bonding medium coating 4, the Luban stone bonding medium coating 4 is sprayed with aggregate sand 5, and the Luban stone bonding medium coating 4 is made of pure acrylic emulsion combined with inorganic weather-resistant pigments and fillers, auxiliary The Luban stone bonding medium coating 4 includes the raw materials of the following weight components: 70-80 parts of inorganic weather-resistant pigments, 10-20 parts of fillers, 5-10 parts of auxiliary agents, and the inorganic weather-resistant pigments are composed of inorganic mixed oxides Uniformly mixed with nano-metals, inorganic weather-resistant pigments include raw materials wit...

Embodiment 2

[0033] see Figure 1-2 , the present invention provides a kind of technical scheme: a kind of Luban stone coating system, comprises base layer 1, and the upper surface of base layer 1 is coated with putty layer 2, and the outer layer of putty layer 2 is coated with primer layer 3, and primer layer 3 The outer layer is sprayed with Luban stone bonding medium coating 4, the Luban stone bonding medium coating 4 is sprayed with aggregate sand 5, and the Luban stone bonding medium coating 4 is made of pure acrylic emulsion combined with inorganic weather-resistant pigments and fillers, auxiliary The Luban stone bonding medium coating 4 includes the raw materials of the following weight components: 70-80 parts of inorganic weather-resistant pigments, 10-20 parts of fillers, 5-10 parts of auxiliary agents, and the inorganic weather-resistant pigments are composed of inorganic mixed oxides Uniformly mixed with nano-metals, inorganic weather-resistant pigments include raw materials wit...

Embodiment 3

[0038] see Figure 1-2 , the present invention provides a kind of technical scheme: a kind of Luban stone coating system, comprises base layer 1, and the upper surface of base layer 1 is coated with putty layer 2, and the outer layer of putty layer 2 is coated with primer layer 3, and primer layer 3 The outer layer is sprayed with Luban stone bonding medium coating 4, the Luban stone bonding medium coating 4 is sprayed with aggregate sand 5, and the Luban stone bonding medium coating 4 is made of pure acrylic emulsion combined with inorganic weather-resistant pigments and fillers, auxiliary The Luban stone bonding medium coating 4 includes the raw materials of the following weight components: 70-80 parts of inorganic weather-resistant pigments, 10-20 parts of fillers, 5-10 parts of auxiliary agents, and the inorganic weather-resistant pigments are composed of inorganic mixed oxides Uniformly mixed with nano-metals, inorganic weather-resistant pigments include raw materials wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com