Light steel keel fast-connection structure

A technology of fast connection and light steel keel, which is applied in the direction of building components, building structure, construction, etc., can solve the problems of easy deformation, complexity and low construction efficiency of the keel frame, and achieve the convenience of modular installation, improvement of firmness, and construction high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

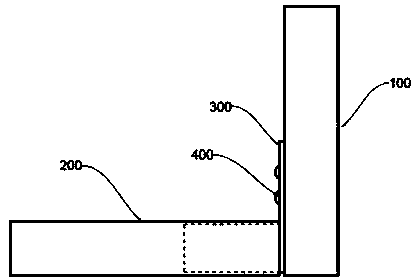

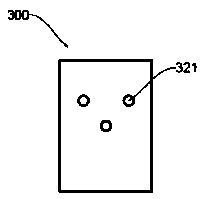

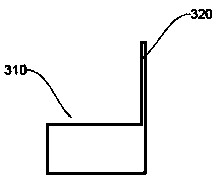

[0036] Reference attached Figure 1-8 , a light steel keel quick connection structure, comprising a longitudinal keel 100, a horizontal keel 200 perpendicular to the longitudinal keel 100, the longitudinal keel 100 and the horizontal keel 200 are fixedly connected by a right-angle connector 300, and the right-angle connector 300 includes The horizontal insertion part 310 inserted into the keel groove of the horizontal keel 200 and the longitudinal connecting plate 320 for connecting the longitudinal keel 100, the horizontal insertion part 310 and the inner wall of the keel groove of the horizontal keel 200 are fit and clamped, and the side panel of the longitudinal keel 100 is connected to the The longitudinal connecting plate 320 is bonded and connected, and the side panels of the longitudinal keel 100 and the longitudinal connecting plate 320 are uniformly provided with a plurality of groups of first through holes from bottom to top, and the longitudinal connecting plate 320 ...

Embodiment 2

[0041] Reference attached Figure 9-17, a light steel keel quick connection structure, including a longitudinal keel 100, a horizontal keel 200 perpendicular to the longitudinal keel 100, the longitudinal keel 100 and the horizontal keel 200 are fixedly connected by a right-angle connector 300, and the right-angle The connector 300 includes a horizontal insertion part 310 for inserting into the keel groove of the horizontal keel 200 and a longitudinal connecting plate 320 for connecting the longitudinal keel 100 , the horizontal insertion part 310 is attached to the inner wall of the keel groove of the horizontal keel 200 The side panel of the longitudinal keel 100 is fitted and connected with the longitudinal connecting plate 320, and the side panels of the longitudinal keel 100 and the longitudinal connecting plate 320 are uniformly opened in sequence from bottom to top. A set of first through holes, the longitudinal connection plate 320 is provided with a connection structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com