Composite microbial treatment agent for fermenting silage and hay silages and preparation method thereof

A technology of compound microorganisms and treatment agents, applied in the biological field, can solve the problems of low overall utilization rate, death of dynamic storage materials, moldy silage, etc., and achieve the effects of improving taste, increasing nutritional value, and reducing ammonia nitrogen content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

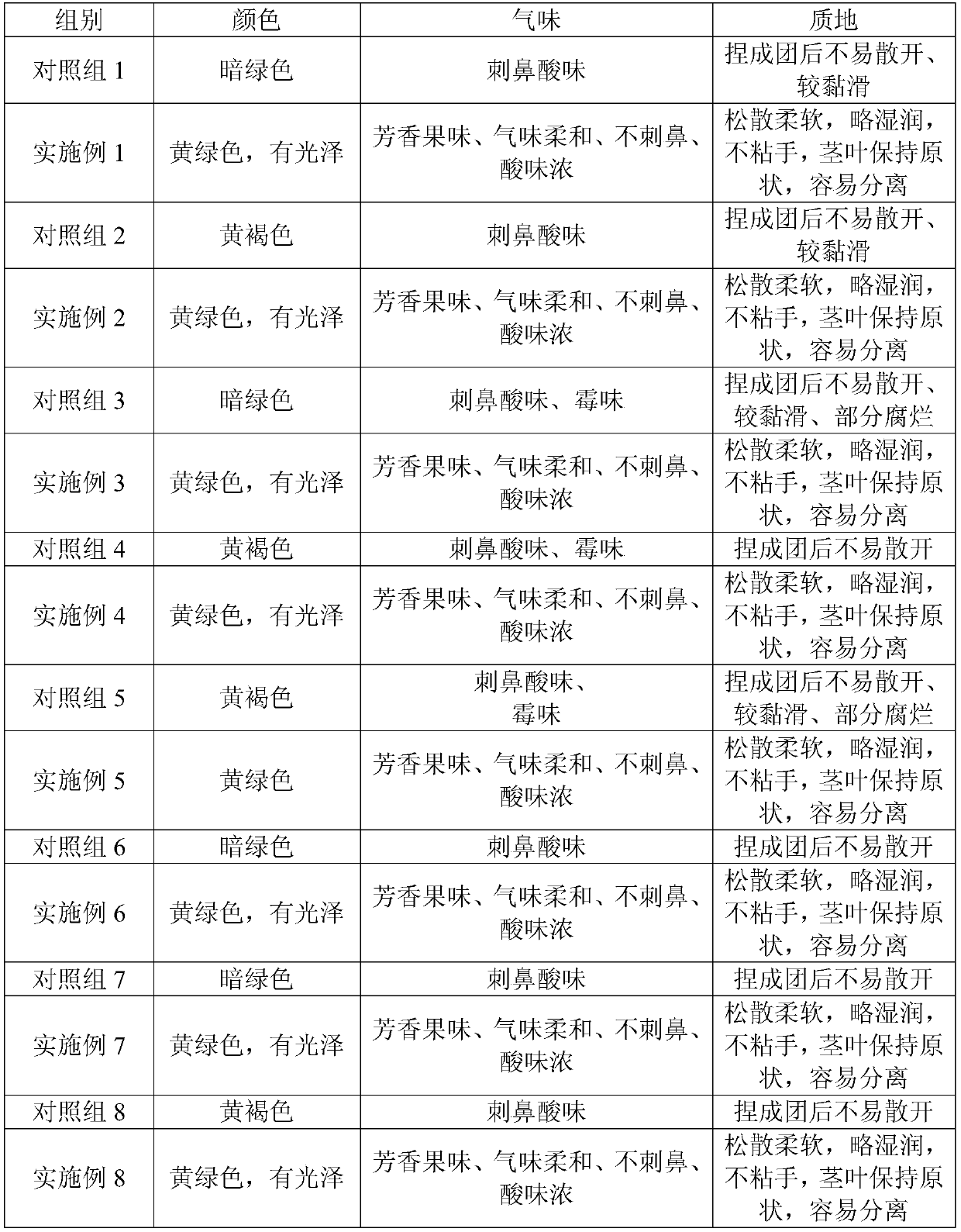

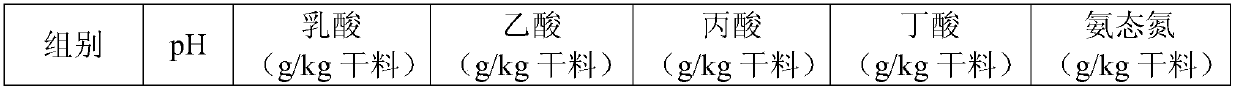

Examples

Embodiment 1

[0017] The number of effective viable bacteria after the fermentation of the microbial bacterial agent is 5.6×10 9 CFU / mL, including 30 parts of Lactobacillus plantarum, 20 parts of Bacillus coagulans, 30 parts of Lactobacillus rhamnosus and 20 parts of Lactobacillus Brucella, in parts by weight.

[0018] The crop stalks used for silage are whole corn stalks, crush the crop stalks to 2-3cm, control the water content of the material to 65%, the amount of material per ton of silage / yellow silage is 250mL, and the compound microbial agent is mixed with 2 kg of water per 200mL , sprayed into the silage / yellow silage material with a sprayer, tied tightly with a baling and coating machine, and the material moisture was fermented at 33-35° C. for 26 days to obtain silage.

Embodiment 2

[0020] The number of effective viable bacteria after the fermentation of the microbial bacterial agent is 8.5×10 9 CFU / mL, including 30 parts of Lactobacillus plantarum, 30 parts of Bacillus coagulans, 20 parts of Lactobacillus rhamnosus and 20 parts of Lactobacillus Brucella, in parts by weight.

[0021] The crop stalks used for silage are the whole corn stalks. Crush the crop stalks to 2-3cm, control the water content of the material to 60%, the amount of material per ton of silage / yellow silage is 300mL, and the compound microbial agent is mixed with 2 kg of water per 200mL , sprayed into the silage / yellow silage material with a sprayer, tied tightly with a baling and coating machine, and the material moisture was fermented at 30-35° C. for 28 days to obtain silage.

Embodiment 3

[0023] The number of effective viable bacteria after the fermentation of the microbial bacterial agent is 7.6×10 9 CFU / mL, including 25 parts of Lactobacillus plantarum, 30 parts of Bacillus coagulans, 20 parts of Lactobacillus rhamnosus and 25 parts of Lactobacillus Brucella, in parts by weight.

[0024] The crop straw used for silage is wheat straw, and the crop straw is crushed to 2-3cm, and the water content of the material is controlled to 60%. The sprayer is sprayed into the silage / yellow silage material, and it is tightly bound with a baling and wrapping machine. The moisture content of the material is fermented at 28-33°C for 32 days to obtain silage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Effective viable count | aaaaa | aaaaa |

| Effective viable count | aaaaa | aaaaa |

| Effective viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com