Escalator floor slab support structure and support frame

A technology for escalators and supporting structures, which is applied to elevators, transportation and packaging in buildings. It can solve problems such as welding and assembly errors of support frames, increased demand for adjustment of support frames, and difficulties in adjusting the width of escalators, so as to ensure assembly Clearance, high assembly efficiency, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

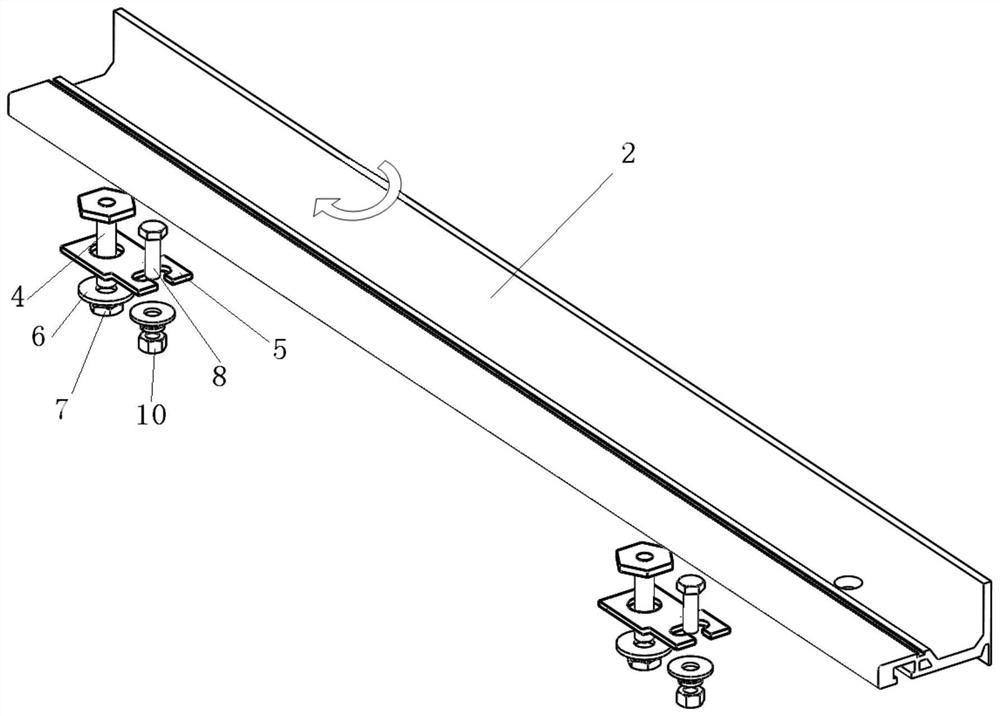

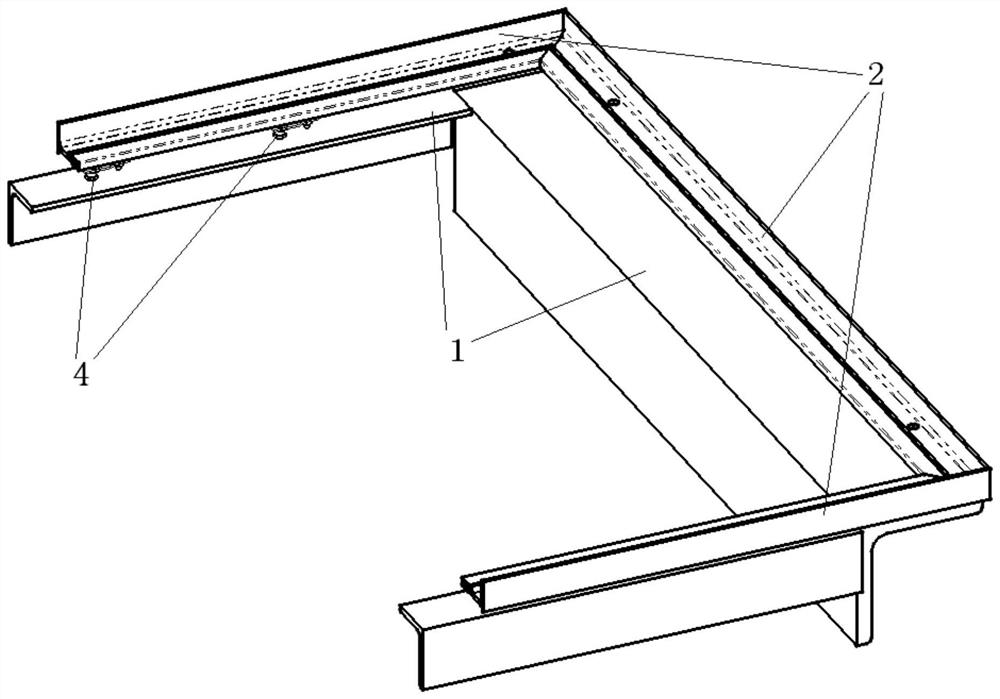

[0037] Such as figure 1 , figure 2 and image 3 As shown, the escalator floor plate support structure includes a support frame 2, a locking bracket 5, a support bolt 4, and a displacement bolt 8;

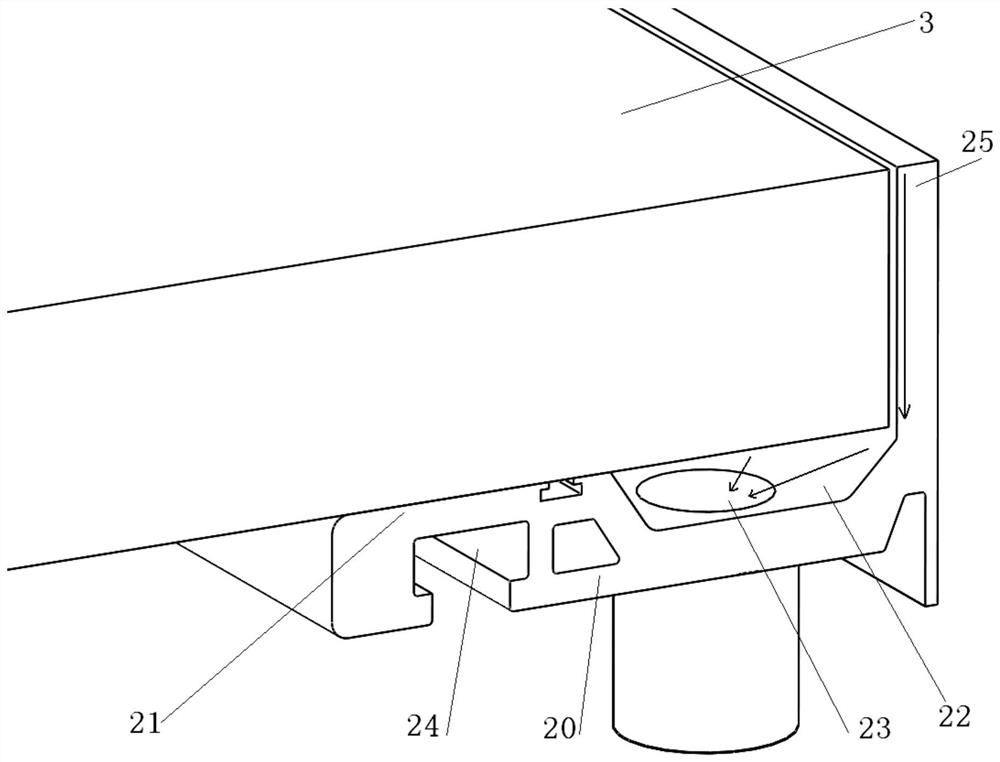

[0038] The supporting frame 2 includes a vertical surface 25 and a horizontal surface 20 that are vertically connected and fixed together;

[0039] The transverse surface 20 includes a supporting surface 21 and a sump 22;

[0040] The sump 22 is located between the supporting surface 21 and the vertical surface 25;

[0041] The bottom of the sump 22 is provided with a drainage hole 23;

[0042] The back of the support surface 21 is provided with a T-shaped groove 24;

[0043] The locking bracket 5 is provided with a support hole and a displacement hole;

[0044] The displacement bolt 8 has a head outer diameter larger than the width of the vertical part of the T-shaped slot 24 and smaller than the width of the transverse part of the T-shaped slot 24, and an outer diameter of ...

Embodiment 2

[0054] Based on the supporting structure of the escalator floor plate in Embodiment 1, the displacement hole is a waist-shaped hole.

[0055] In the supporting structure of the escalator floor plate in the second embodiment, the displacement bolt 8 can move in the width direction of the locking bracket 5, therefore, under the condition that the support bolt 4 is fixed, the translation of the supporting frame 2 in the width direction of the truss 1 can be realized .

Embodiment 3

[0057] Based on the first embodiment, the escalator floor support structure further includes a locking nut 7;

[0058] The lock nut 7 is sleeved on the screw rod of the support bolt 4 and is located between the lock bracket 5 and the escalator truss 1 .

[0059] Embodiment 1. In the supporting structure of the floor plate of the escalator, the locking nut 7 and the washer 6 are used together with the supporting bolt 4 to fix the locking bracket 5 after the position of the supporting frame 2 is adjusted.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com