Transfer box automatic locking device

A technology of automatic lock and turnover box, which is applied in the field of luggage, can solve the problems of unfavorable disassembly and recycling, safety performance cannot be guaranteed, and the advent of the world, so as to reduce solid waste and environmental pollution, improve market competitiveness, The effect of reducing packaging costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

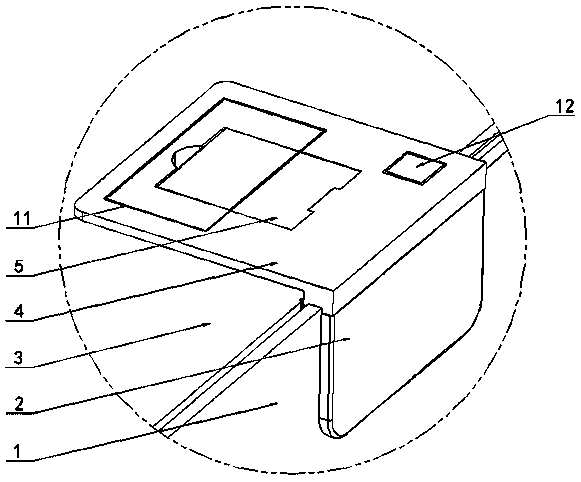

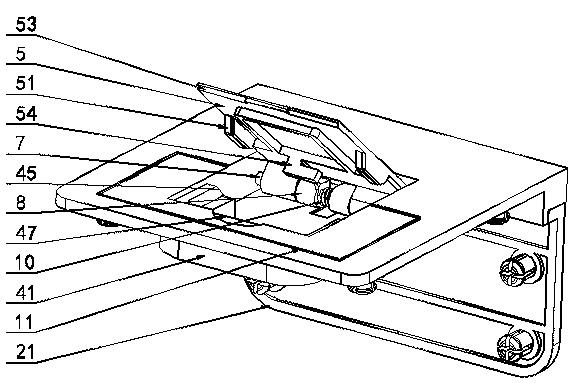

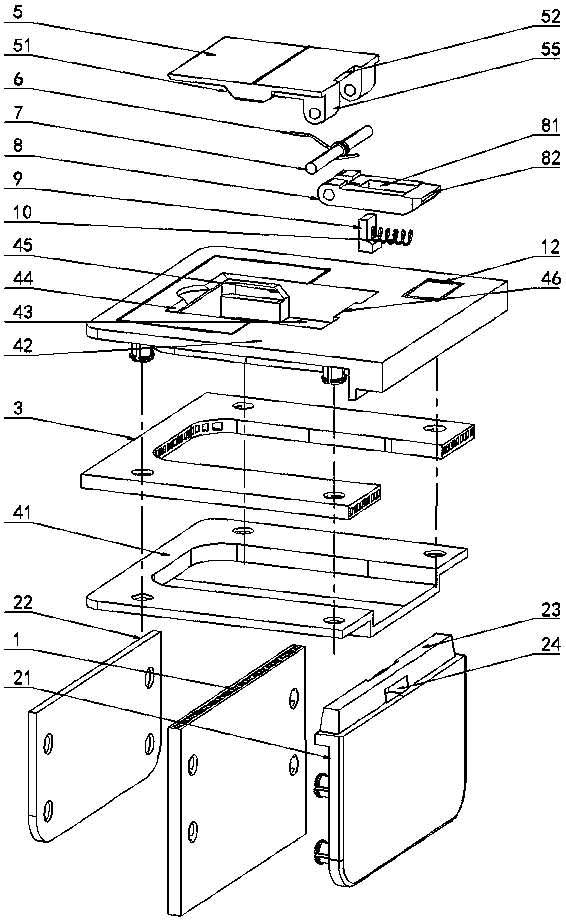

[0019] Figure 1 to Figure 5 As shown, it is a specific embodiment of the automatic locking device for the turnover box created by the present invention, which includes the box cover locking mechanism 4 fixed on the box cover 3 by the box cover fixing plate 41, and fixed on the box body by the box body fixing plate 22. The box body locking mechanism 2 on 1, the box lid locking mechanism 4 includes the box lid fixing seat 42, the handle 5 for unlocking and opening the box, the deadbolt body 8, the deadbolt positioning block 9, the spring 10, and the box lid is fixed The seat 42 is correspondingly provided with a handle notch 43 matched with the handle 5 for unlocking and unpacking and a deadbolt chute 48 that is slidably matched with the deadbolt body 8 and communicated with the notch 43 of the handle. It is arranged on the handle notch 43 and is provided with a rotating arm 55. The dead bolt body 8 is provided with a spring groove 81. The dead bolt body 8 is slidably arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com