Inverted defoaming device for conductive adhesive and application method thereof

A conductive adhesive and defoaming technology, applied in separation methods, chemical instruments and methods, circuits, etc., can solve the problems of unable to discharge a large amount of air from the piston and conductive adhesive, continuous and stable supply of conductive adhesive, and deterioration of dispensing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

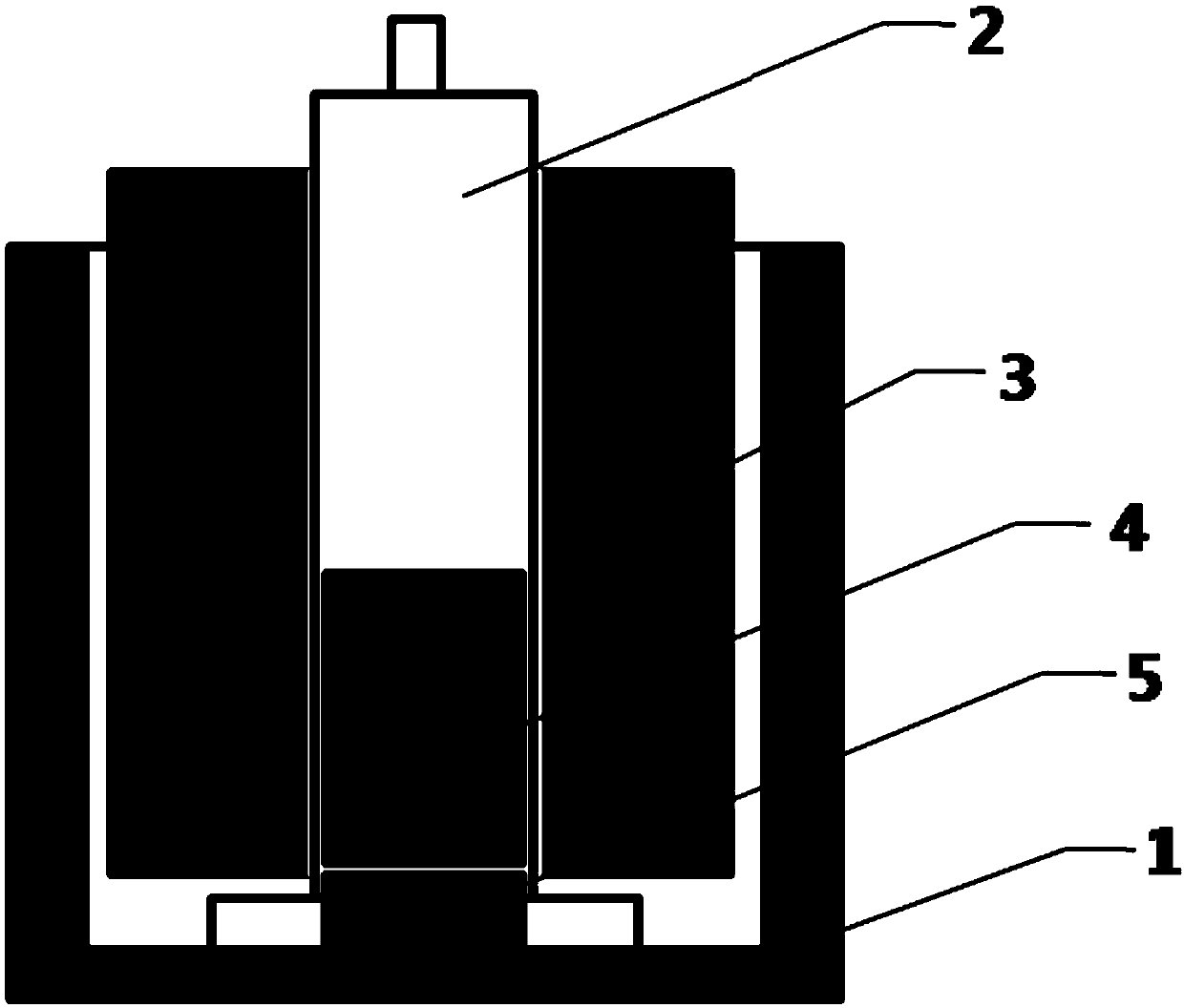

[0024] This embodiment provides a kind of conductive glue pouring defoaming device, such as figure 2 , the conductive adhesive inverted defoaming device includes a centrifuge, the centrifuge is provided with a base 1, a needle tube fixing fixture 3 and a needle tube 2, the outer shape of the base 1 is adapted to the centrifuge, and the inside of the base 1 is drawn out empty, and the inner surface is a thread structure; the needle tube fixing fixture 3 is a circular cylinder, and the outer surface of the needle tube fixing fixture 3 is a thread structure and matches the thread structure of the inner surface of the base 1; the outer surface of the typical needle tube fixing fixture of the present invention The size of the diameter is 0.2 mm smaller than the inner diameter of the base 1, and the inner diameter of a typical needle tube fixing fixture is 0.2 mm larger than that of the needle tube 2. Under this size, the devices are more closely matched.

[0025] Further, the need...

Embodiment 2

[0028] This embodiment provides a method for using a conductive adhesive inverted defoaming device, including the conductive adhesive inverted defoaming device provided in Example 1, specifically including the following steps:

[0029] S1. Install the conductive adhesive fixing device 3 on the base of the centrifuge;

[0030] S2. Pack the conductive adhesive in the barrel into the needle tube 2 after returning to temperature;

[0031] S3. Stand the needle tube 2 upside down, pull the piston of the needle tube 2 back to the bottom, break the piston push rod, and insert the needle tube upside down into the needle tube fixing fixture 3;

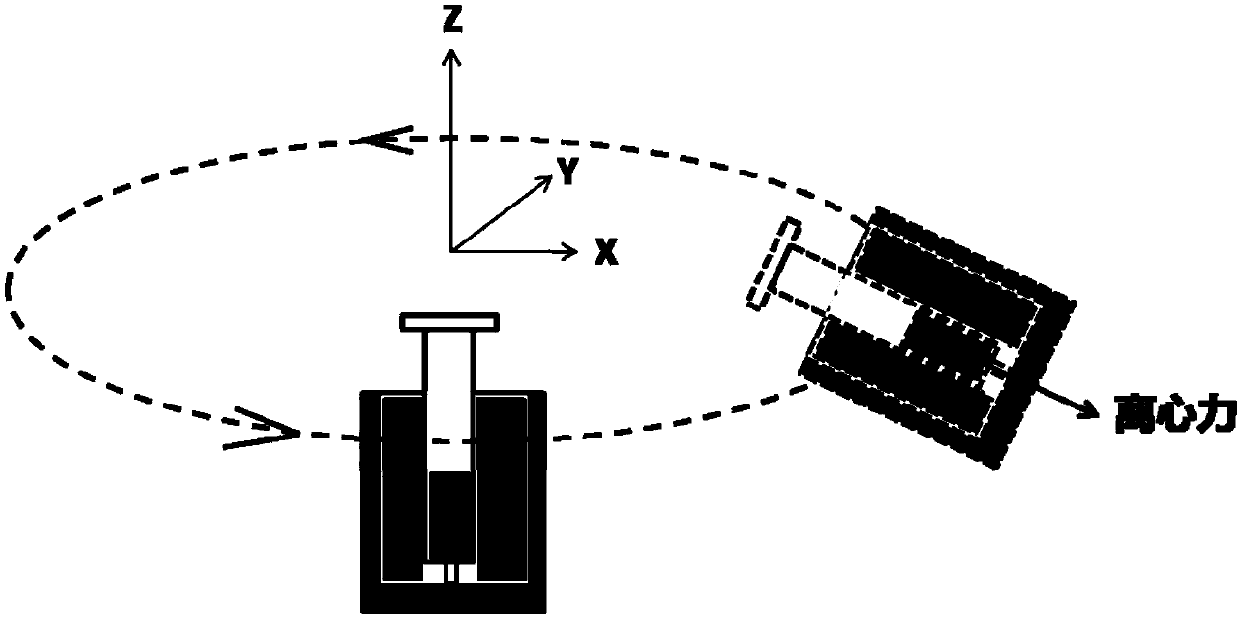

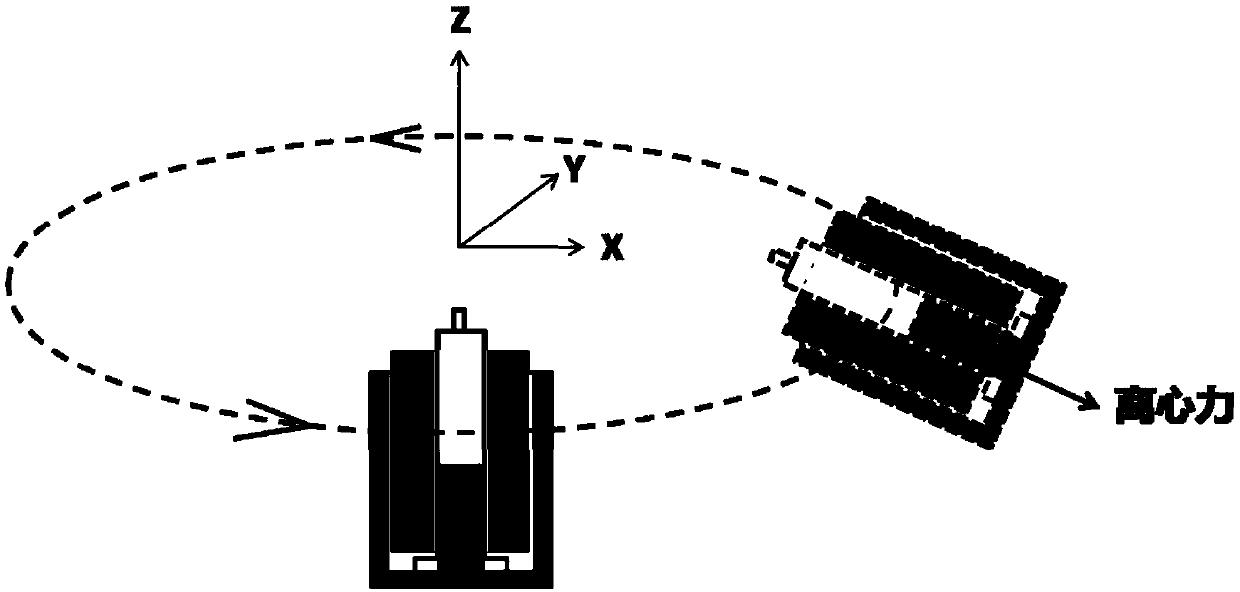

[0032] S4, together with the needle tube fixing fixture 3 and the needle tube 2, put them all into the base 1 of the centrifugal rotating device for centrifugal degassing, at this time, the centrifugal force on the conductive adhesive is outward, so that the air bubbles in the conductive adhesive are separated from the tip of the needle tube;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com