Nitrogen-doped hollow carbon sphere/nickel sulfide/graphene ternary active multilayer/multi-structure composite material and

A technology of hollow carbon spheres and composite materials, applied in the field of dye-sensitized solar cells, to achieve good electrochemical stability, no pollution to the environment, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

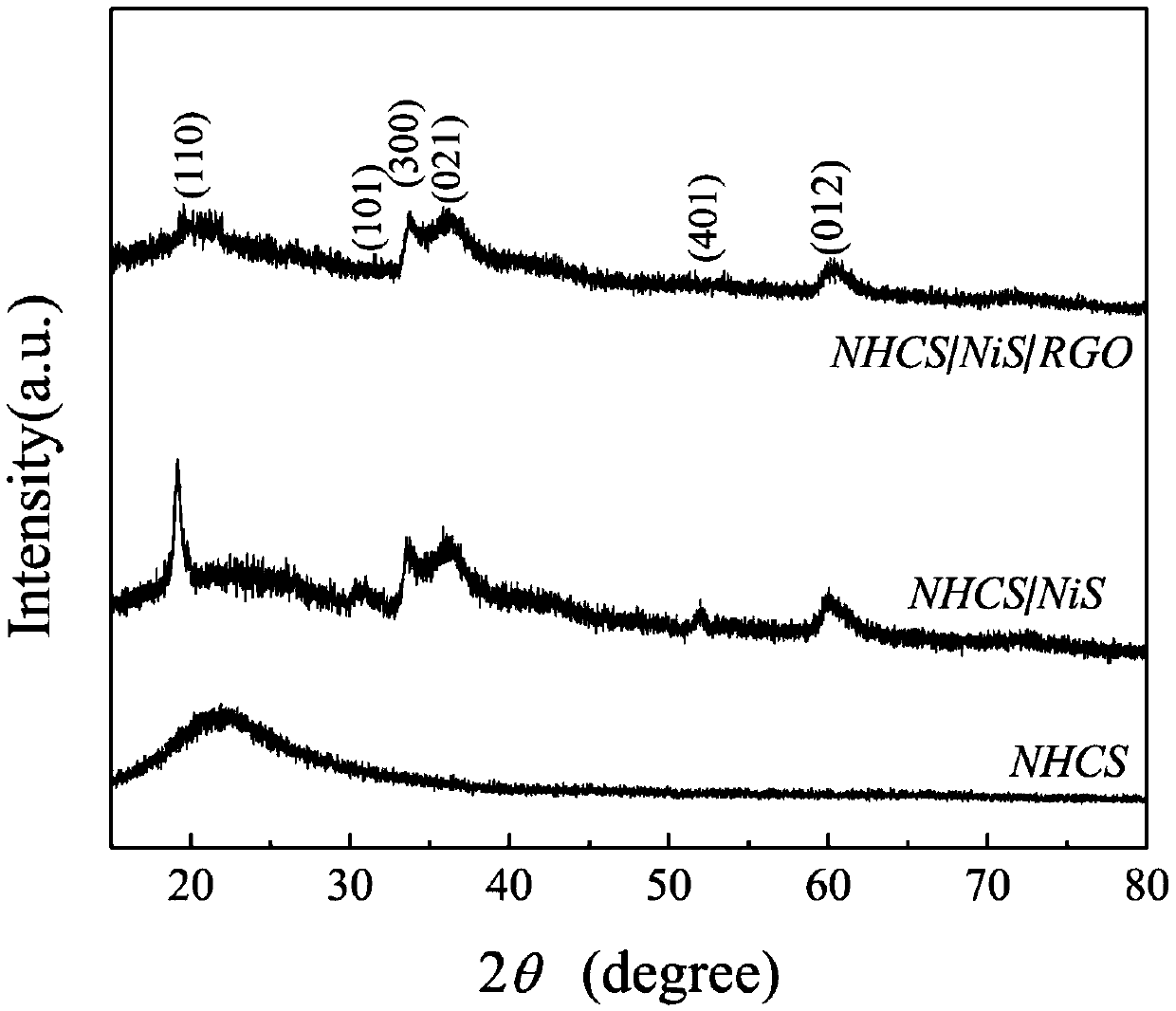

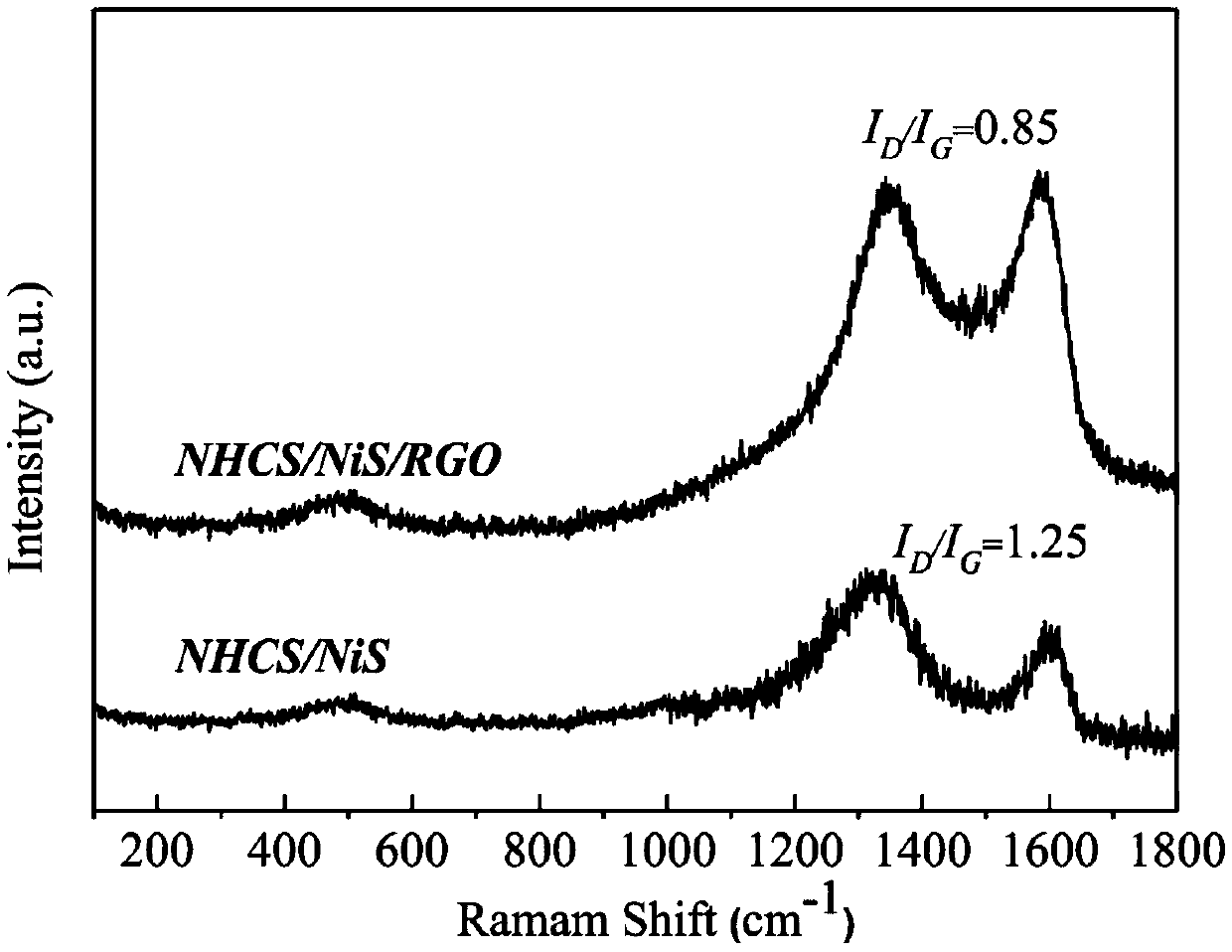

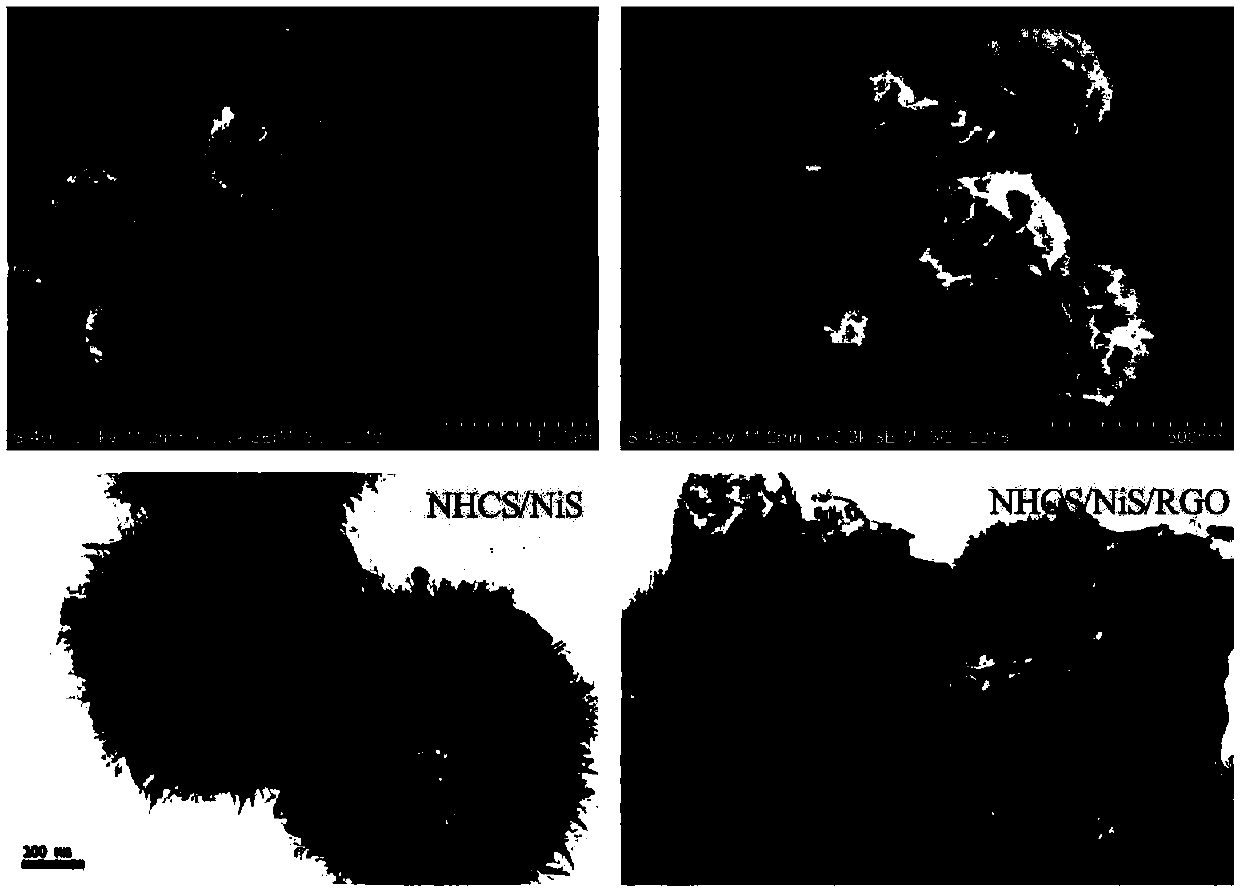

Examples

Embodiment 1

[0045] A preparation method of a nitrogen-doped hollow carbon sphere / nickel sulfide / graphene ternary active multilayer / multiple structure composite material: comprising the following steps:

[0046] (1) 2mL tetraethyl orthosilicate (C 8 h 20 o 4 Si) and 0.04g of dopamine hydrochloride (C 8 h 11 NO 2 HCl) is slowly poured into the mixed solution in turn, and continuously stirred for 36 hours until it is fully mixed;

[0047] Described mixed solution is dehydrated alcohol (C 2 h 6 O), ammonia (NH 3 ·H 2 O, 25%), and deionized water (H 2 O), the volume ratio of the three is 5:1:8.

[0048] (2) After cooling to room temperature, the solution in step (1) is subjected to high-speed centrifugation, and the centrifugation speed is controlled to be 8000-10000r / min, and the obtained precipitate is repeatedly centrifuged and washed with deionized water for 3-4 times until the supernatant It is a clear and transparent liquid, and the obtained final product is dried in a freeze ...

Embodiment 2

[0065] A kind of silicon dioxide / nitrogen-doped hollow carbon spheres (SiO 2 / N-doped carbon spheres) preparation method: comprise the following steps:

[0066] (1) 2mL tetraethyl orthosilicate (C 8 h 20 o 4 Si) and 0.04g of dopamine hydrochloride (C 8 h 11 NO 2 HCl) is slowly poured into the mixed solution successively, and continuously stirred for 36h until it is fully mixed;

[0067] Described mixed solution is dehydrated alcohol (C 2 h 6 O), ammonia (NH 3 ·H 2 O, 25%), and deionized water (H 2 O), the volume ratio of the three is 5:1:8.

[0068] (2) After cooling to room temperature, the solution in step (1) is subjected to high-speed centrifugation, and the centrifugation speed is controlled to be 8000-10000r / min, and the obtained precipitate is repeatedly centrifuged and washed with deionized water for 3-4 times until the supernatant It is a clear and transparent liquid, and the obtained final product is dried in a freeze dryer for 10 hours. The temperature o...

Embodiment 3

[0071] A preparation method of nickel silicide / nitrogen-doped hollow carbon sphere mixture (NHCS / NiSi composites): comprising the following steps:

[0072] (1) 2mL tetraethyl orthosilicate (C 8 h 20 o 4 Si) and 0.04g of dopamine hydrochloride (C 8 h 11 NO 2 HCl) is slowly poured into the mixed solution successively, and continuously stirred for 36h until it is fully mixed;

[0073] Described mixed solution is dehydrated alcohol (C 2 h 6 O), ammonia (NH 3 ·H 2 O, 25%), and deionized water (H 2 O), the volume ratio of the three is 5:1:8.

[0074] (2) After cooling to room temperature, the solution in step (1) is subjected to high-speed centrifugation, and the centrifugation speed is controlled to be 8000-10000r / min, and the obtained precipitate is repeatedly centrifuged and washed with deionized water for 3-4 times until the supernatant It is a clear and transparent liquid, and the obtained final product is dried in a freeze dryer for 10 hours. The temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com