Gravity sensing automatic vending machine

A vending machine and gravity sensing technology, applied in the field of vending machines, can solve the problems of inability for customers to make choices, troublesome operation process, and long time to pick up goods, and achieve the effect of small deformation, increased deformation space, and good fixed support rods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

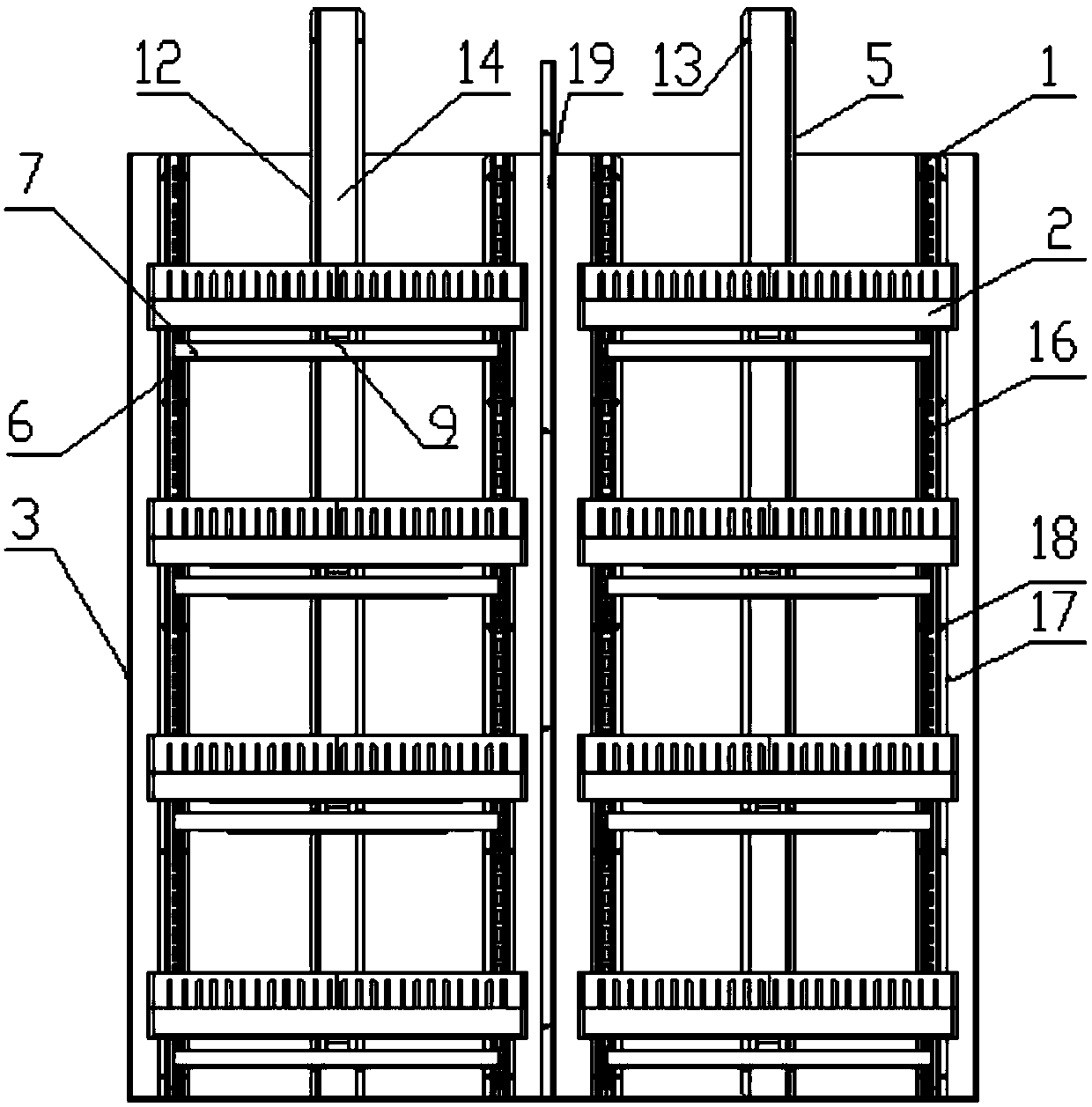

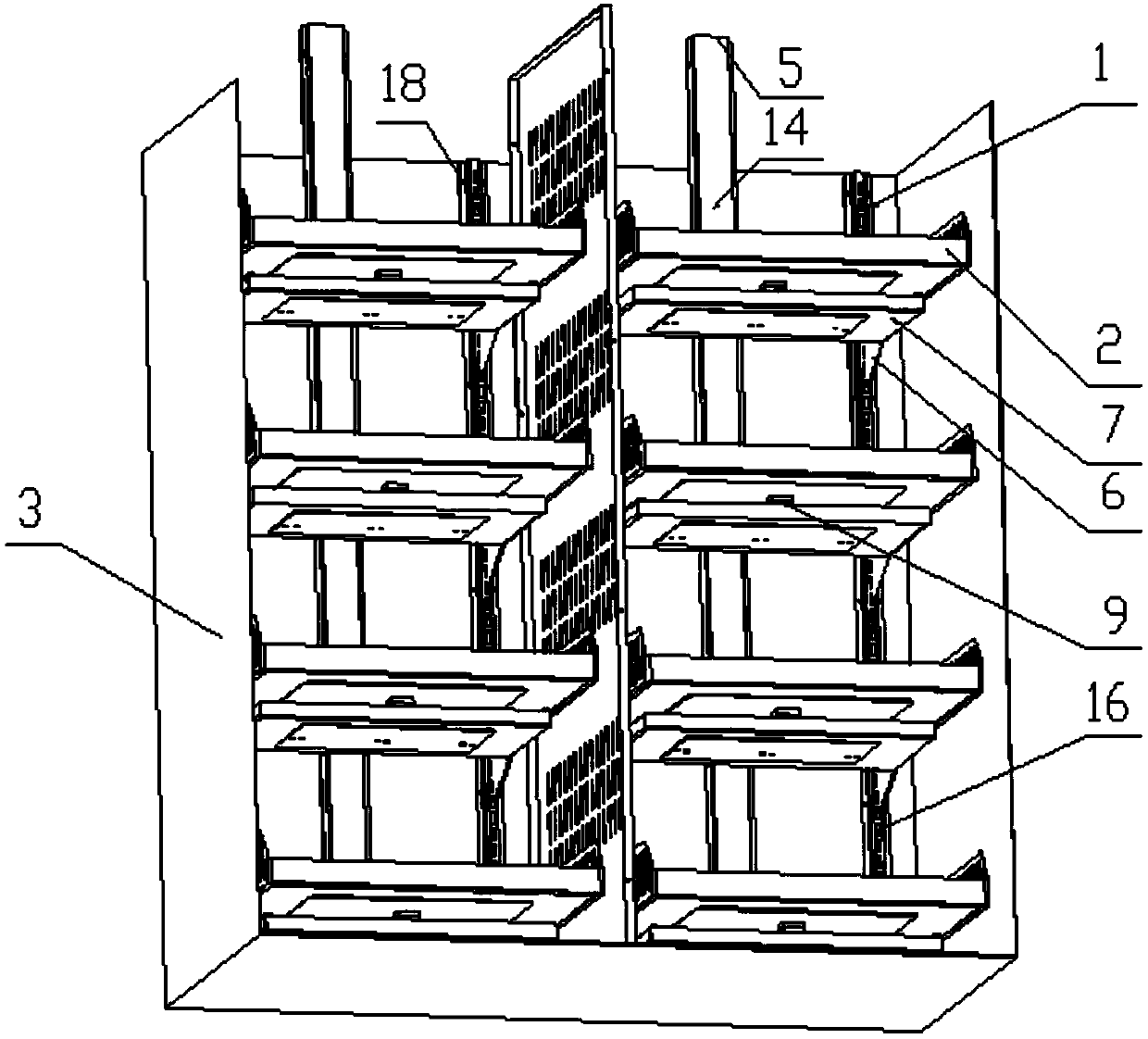

[0027] Such as Figure 1-3 As shown, the present invention provides a gravity-sensing automatic vending machine, comprising a shelf body 3 and a support rod 1; the inner and rear sides of the shelf body 3 are provided with a partition 19, a support rod 1 and a wiring trough 5; the partition 19 is arranged on At the inner and rear central axis of the shelf body 3, there are four sets of support rods 1, and the four support rods 1 are symmetrical to the center of the partition 19. Symmetrical, and a single set of wiring troughs 5 is set at the central axis of two groups of support rods 1; a number of magic holes 16 are equidistantly distributed up and down the support rod 1, and a support frame 7 is arranged on the support rod 1, and the bottom end surface of the support frame 7 has two sides. Both sides are fixedly connected to the clip 6, and the clip 6 is engaged with the magic hole 16; the center point of the top surface of the support frame 7 is provided with a gravity sens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com