Coal mining machine memory cutting system with strong robustness and long and short term memory capability

A long-short-term memory and shearer technology, applied in the field of signal processing and deep learning, can solve problems such as low accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

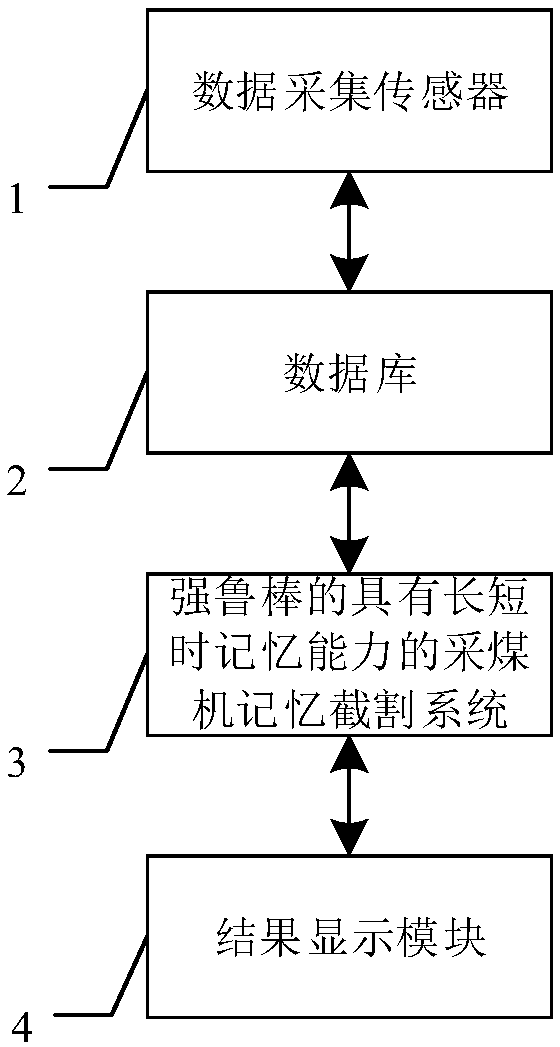

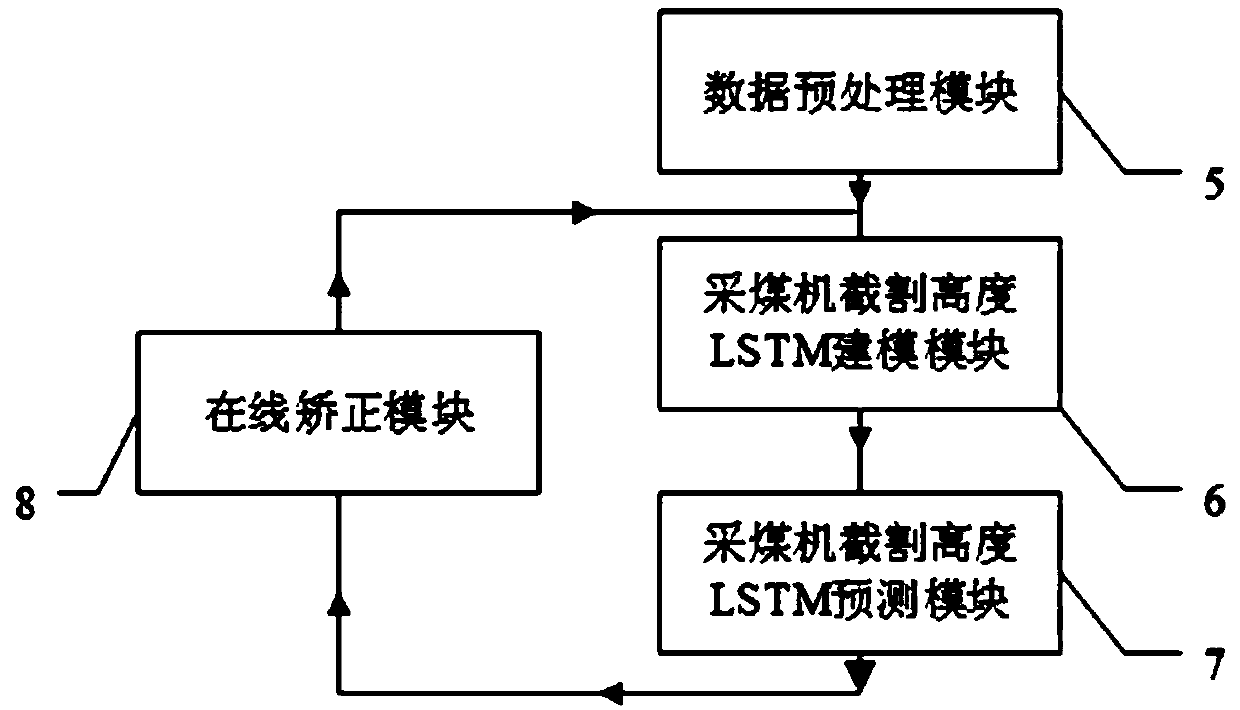

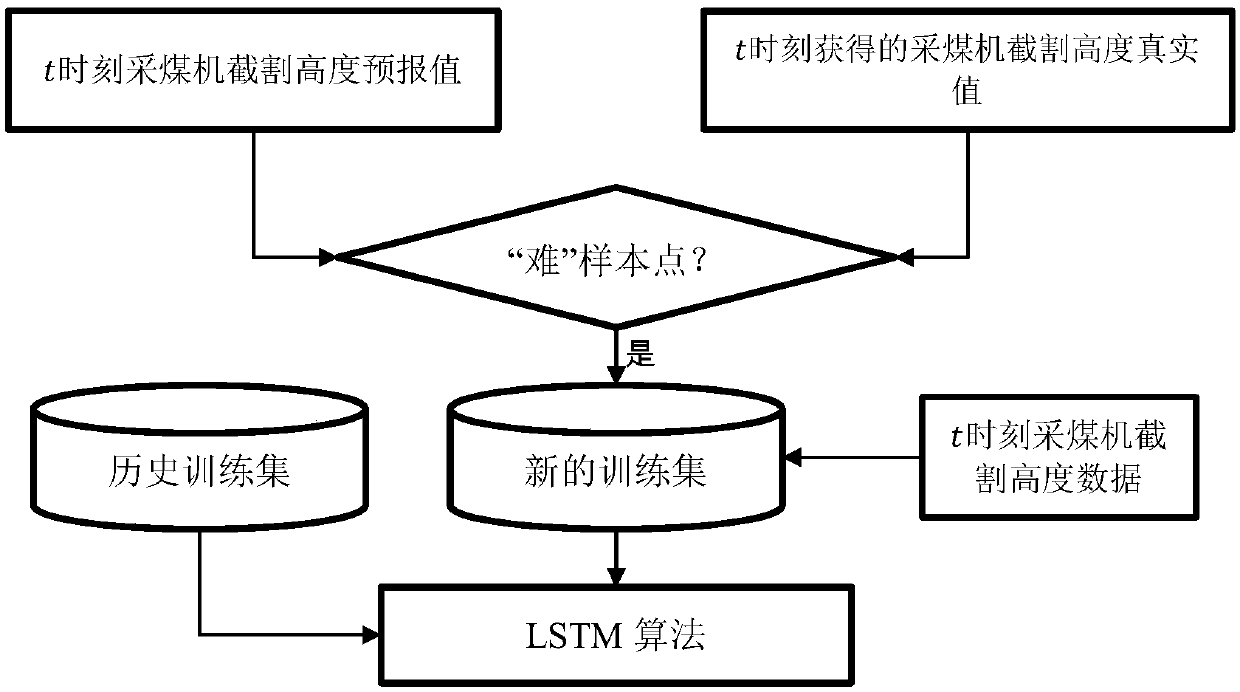

[0051] refer to figure 1 , figure 2 , image 3 , a shearer memory cutting system with strong long-short-term memory capability, including data preprocessing module 5, shearer cutting height long-short-term memory network model (LSTM) modeling module 6, shearer cutting Highly long short-term memory network model (LSTM) prediction module 7 and online correction module 8. The data acquisition sensor 1, the database 2, the robust shearer memory cutting system 3 with long-short-term memory capability and the result display module 4 are connected in sequence, and the data acquisition sensor 1 performs the historical cutting height signal of the shearer. The data is collected and stored in the database 2. The database 2 contains historical shearer cutting height data to provide data support for a robust shearer memory cutting system 3 with long and short-term memory capabilities. The results predicted by the strong and robust shearer memory cutting system 3 with long and short-te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com