Optical fiber cutter capable of instantly storing cut optical fibers

A technology of optical fiber cutter and optical fiber, which is applied in the coupling direction of optical waveguide, can solve the problems of inability to realize the arc swing of the pendulum rod, complex structural design, and increased operation steps, so as to ensure the smoothness of automatic knife return and reduce the cutting process Effect of steps, stable opening and closing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

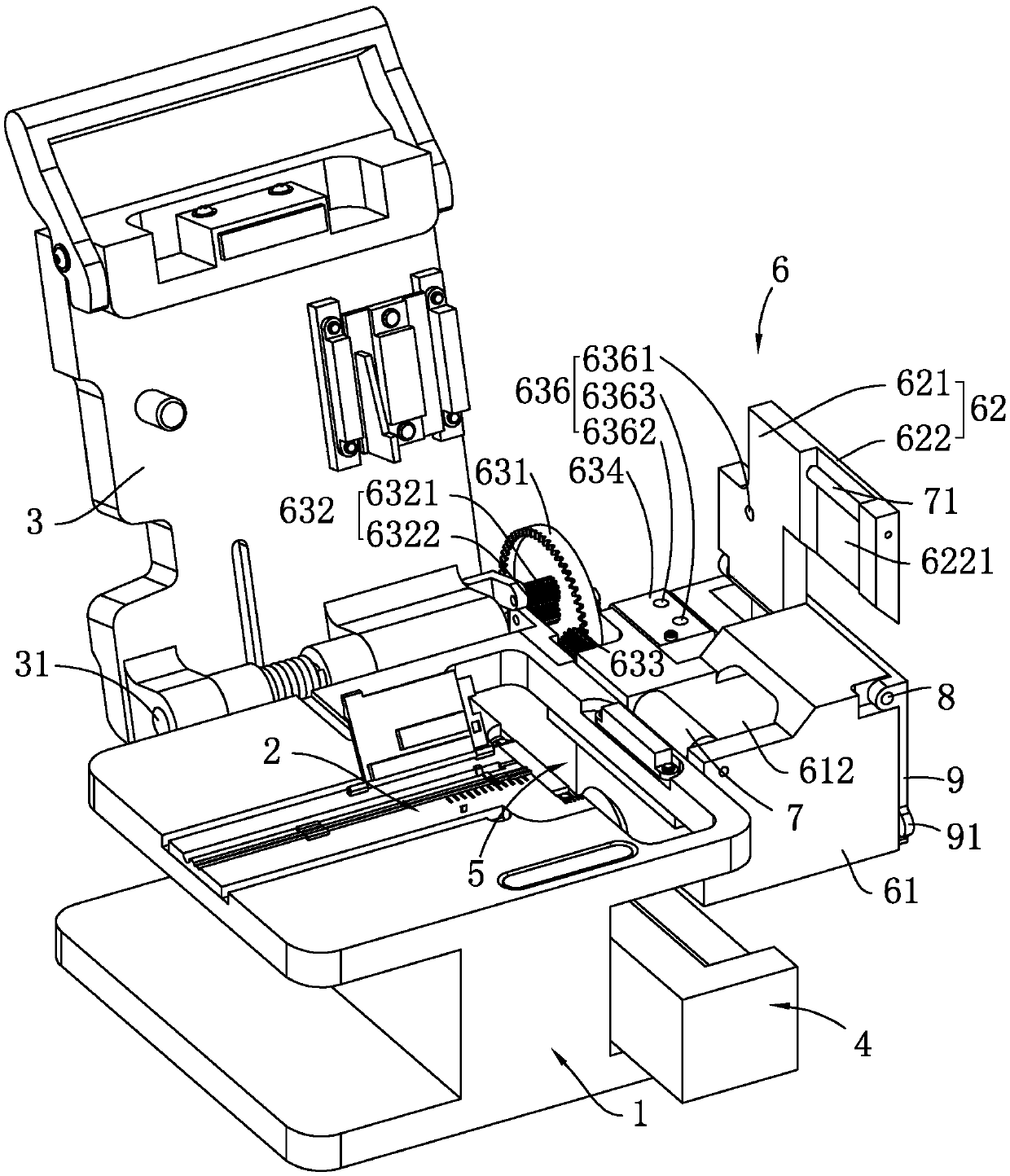

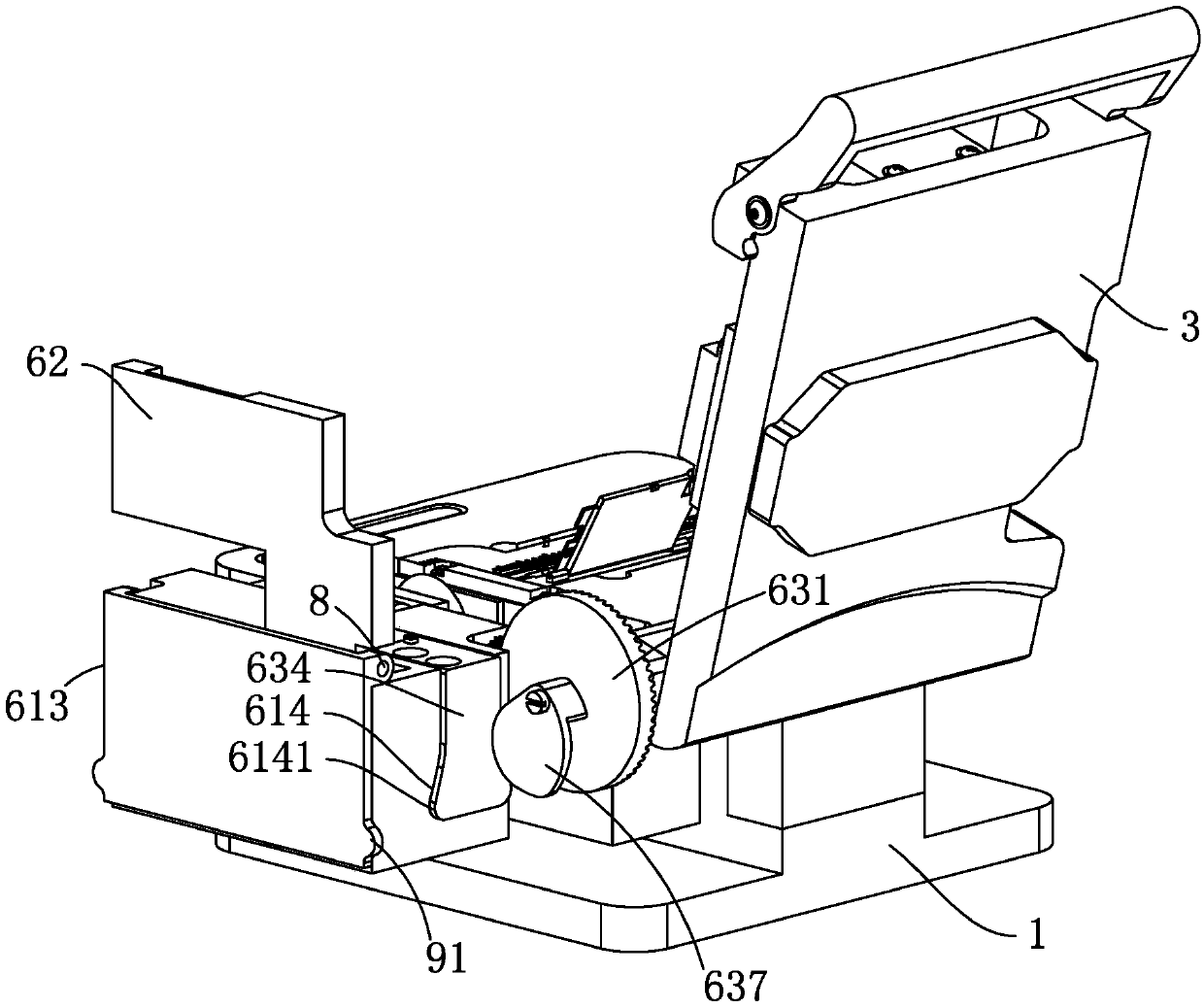

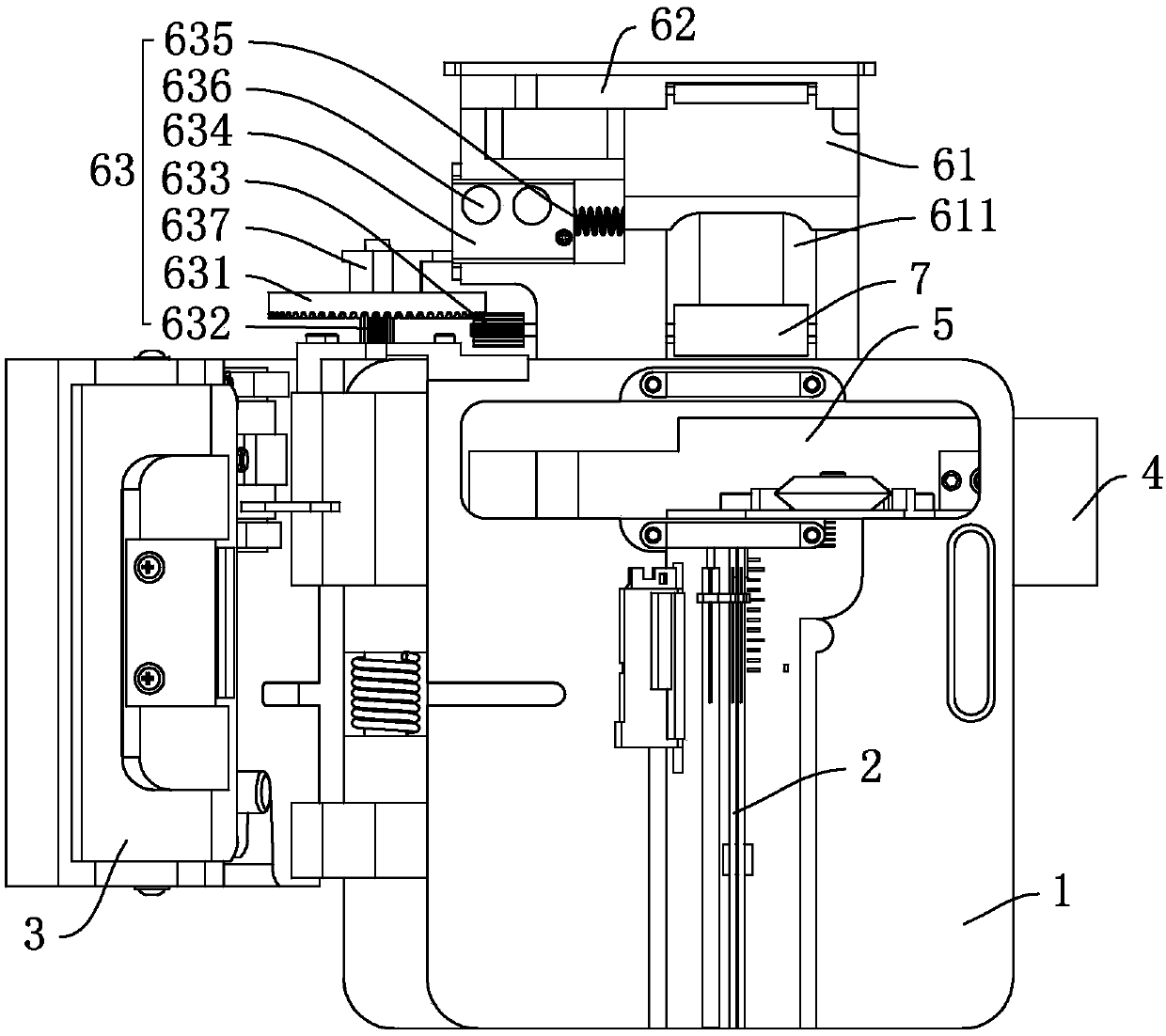

[0064] Reference figure 1 , Which is an optical fiber cleaver capable of instantaneously accommodating broken optical fibers after cleavage according to the present invention, including a main body 1, a gland 3 and a sliding cutting assembly 4. Among them, the main body 1 has an optical fiber guide portion 2 arranged on the upper surface, and its main function is to position the optical fiber; the gland 3 is hinged on a horizontal gland shaft 31 arranged on the main body 1 and parallel to one side of the optical fiber guide portion 2. On one side of the main body 1, the pressing cover 3 is turned up and opened relative to the upper surface of the main body 1 with the horizontal pressing shaft 31 as an axis, and is turned down to cover the optical fiber guide portion 2; the sliding cutting assembly 4 is slidably connected to the main body 1, It is located below the notch 5 at the end of the fiber guiding end, and can be configured to cut the optical fiber through the notch 5 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com