Integral gas heating device

A gas heating device, integrated technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of difficult adjustment of heating speed and power, interference of experimental results, precision interference, etc., and achieve modularization Layout, enhanced layout flexibility, fast and uniform heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

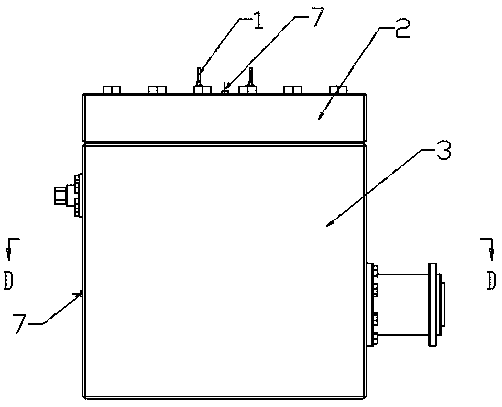

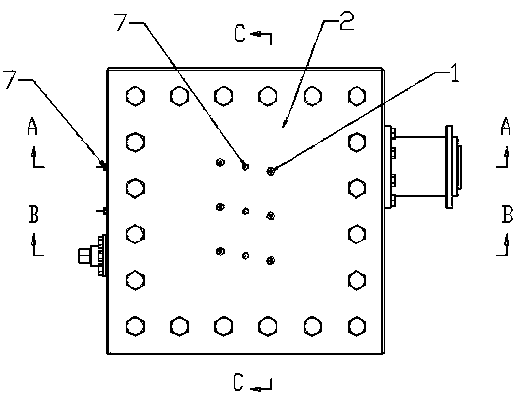

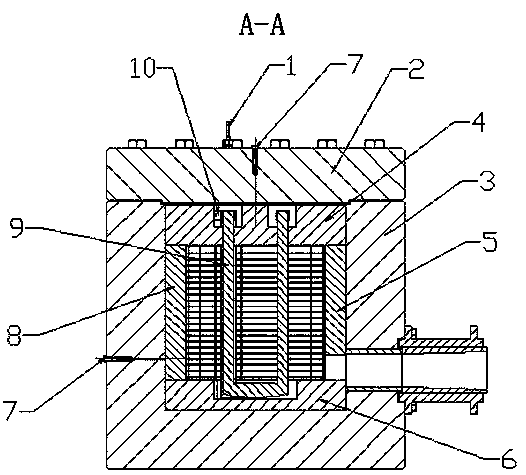

[0036] figure 1 , 2 A front view and a top view of an integral gas heating device are shown; image 3 , 4 , 5 shows figure 2 Schematic cross-sections at A-A, B-B and C-C. This integral gas preheating device includes a heating core, an electrode 1, a heater shell 3, an end cover 2 and a thermocouple probe 7, the upper ceramic bushing 4 has a square groove, and the upper end of the U-shaped silicon carbide rod 9 extends to the The silicon carbide rod clip 10 is clamped in the square groove, and the silicon carbide rod clip 10 is connected with the electrode 1 inserted on the end cover 2 through an aluminum strip, and supplies power to the U-shaped silicon carbide rod 9 . 9 sets of U-shaped silicon carbide rods are set in the heating inner core, and the heating inner core uses the upper ceramic bushing 4, the outlet ceramic b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com