An intermittent fixed explosives incineration treatment device

A technology for processing devices and explosives, applied in the direction of incinerators, combustion types, combustion methods, etc., can solve major combustion explosion accidents, serious injuries, etc., and achieve a high level of safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

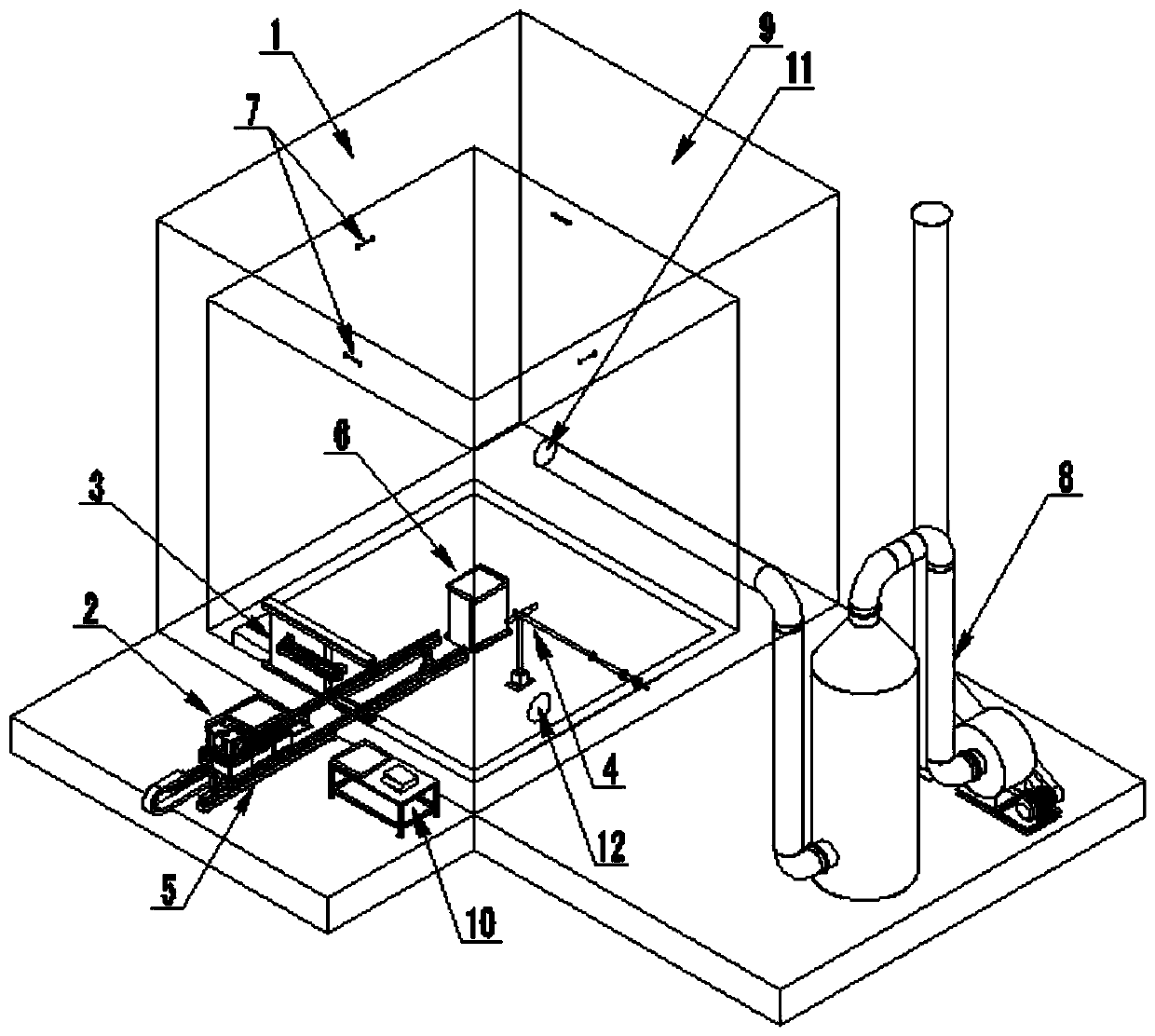

[0025] The present invention provides an intermittent fixed explosives incineration treatment device, which realizes a single feeding of 10kg TNT equivalent through automatic ignition and remote operation, and a maximum daily processing capacity of 100-150kg TNT equivalent, which can ensure the incineration and removal of waste explosives The rate is above 99%.

[0026] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0027] Take the destruction of waste composite propellants as an example, such as figure 1 , 2 As shown, an intermittent fixed explosive incineration treatment device related to the present invention mainly includes an incineration main body 1, a feed transportation device 2, an anti-explosion transfer window 3, an automatic ignition system 4, a feed guide rail 5, an incineration platform 6, Sprinkler system 7, dust absorption device 8, explosion suppression chamber 9, weighing device 10, air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com